Graphene/deimpurity polyaniline-containing anticorrosive coating and preparation method thereof

An anti-corrosion coating, graphene technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problems of single anti-corrosion method, general anti-corrosion effect, limited use scope, etc., to achieve excellent anti-corrosion performance and cheap application scope Pollution-free, wide-ranging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

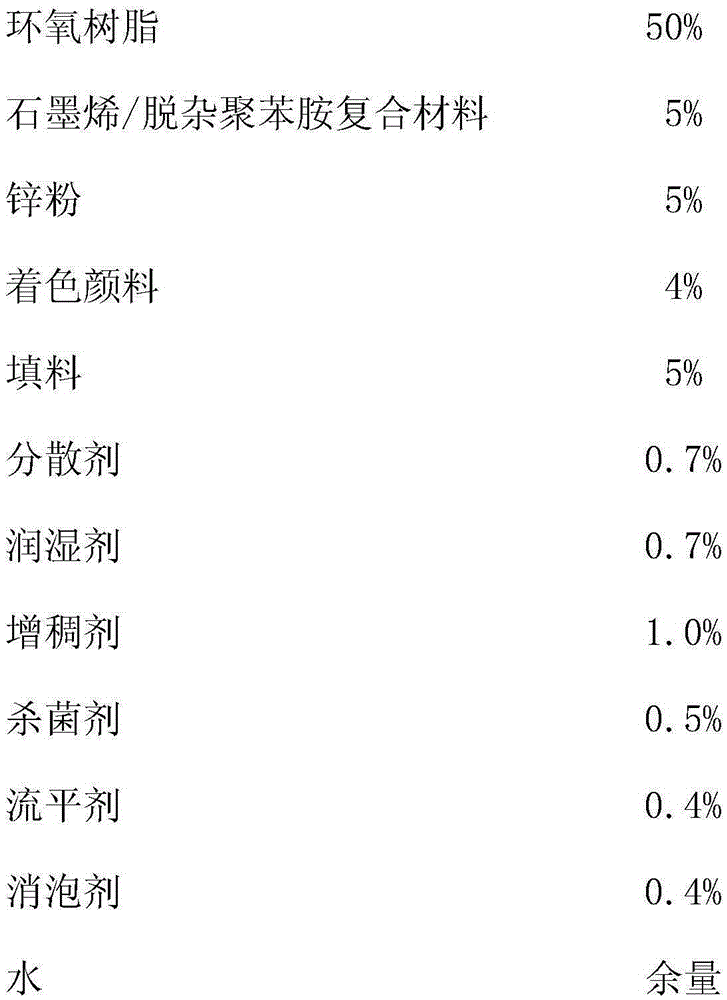

[0019] Proportioning each component according to the following mass percentages:

[0020]

[0021] (1) Prepare a hydrochloric acid solution containing aniline, add 300 mesh graphene and mix evenly, then pre-cool to 0°C, wherein the concentration of aniline is 0.2mol / L, the concentration of hydrochloric acid is 0.3mol / L, and the concentration of graphene is 20mg / mL;

[0022] (2) Prepare an aqueous solution of ammonium persulfate containing hydrochloric acid, and pre-cool to 0° C., wherein the concentration of ammonium persulfate is 0.2 mol / L, and the concentration of hydrochloric acid is 0.3 mol / L;

[0023] (3) Add the dispersion liquid obtained in the first step into the reactor, stir at a constant speed and slowly add the solution prepared in the second step dropwise, control the temperature at 0°C for 5 hours, filter and wash, then put in 0.1mol / L NaOH solution Soak in medium for 2 hours, filter, wash, dry and grind to 250 mesh to prepare graphene / depurified polyaniline c...

Embodiment 2

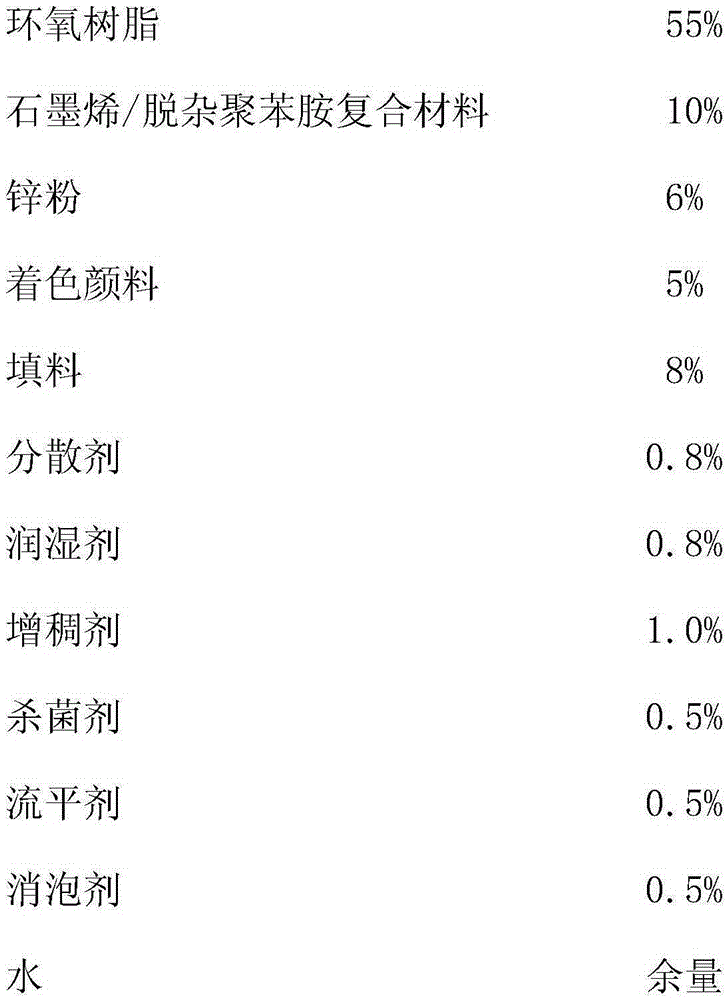

[0026] Proportioning each component according to the following mass percentages:

[0027]

[0028] (1) Prepare a hydrochloric acid solution containing aniline, add 300 mesh graphene and mix evenly, then pre-cool to 8°C, wherein the concentration of aniline is 0.3mol / L, the concentration of hydrochloric acid is 0.4mol / L, and the concentration of graphene is 30mg / mL;

[0029] (2) Prepare an aqueous solution of ammonium persulfate containing hydrochloric acid, and pre-cool to 0°C, wherein the concentration of ammonium persulfate is 0.3mol / L, and the concentration of hydrochloric acid is 0.4mol / L;

[0030] (3) Add the dispersion obtained in the first step into the reactor, stir at a constant speed and slowly add the solution prepared in the second step dropwise, control the temperature at 0°C for 8 hours, filter and wash, and put in 0.2mol / L NaOH solution Soak in medium for 2 hours, filter, wash, dry and grind to 350 mesh to prepare graphene / depurified polyaniline composite mat...

Embodiment 3

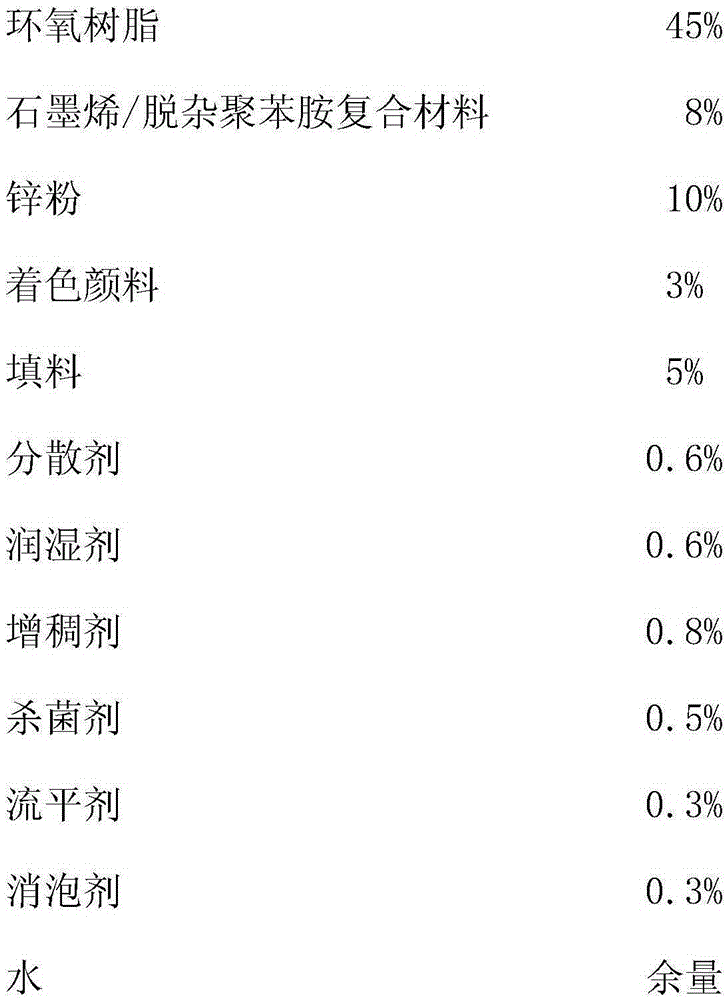

[0033] Proportioning each component according to the following mass percentages:

[0034]

[0035] (1) Prepare a hydrochloric acid solution containing aniline, add 250 mesh graphene and mix evenly, and pre-cool to 5°C, wherein the aniline concentration is 0.5mol / L, the hydrochloric acid concentration is 0.6mol / L, and the graphene concentration is 50mg / mL;

[0036] (2) Prepare an aqueous solution of ammonium persulfate containing hydrochloric acid, and pre-cool to 5° C., wherein the concentration of ammonium persulfate is 0.5 mol / L, and the concentration of hydrochloric acid is 0.5 mol / L;

[0037] (3) Add the dispersion obtained in the first step into the reactor, stir at a constant speed and slowly add the solution prepared in the second step dropwise, control the temperature at 5°C for 6 hours, filter and wash, and put in 0.1mol / L NaOH solution Soak in medium for 4 hours, filter, wash, dry and grind to 250-350 mesh to prepare graphene / depurified polyaniline composite mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com