Method for removing phosphorous based on high-efficiency promotion of spongy iron corrosion in process of nitrogen removal by denitrification

A technology of nitrification and denitrification and sponge iron, which is applied in the field of environmental engineering, can solve the problems of increasing operation and management costs, and achieve the effects of improving phosphorus removal efficiency, improving denitrification effect, and promoting corrosion and phosphorus removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

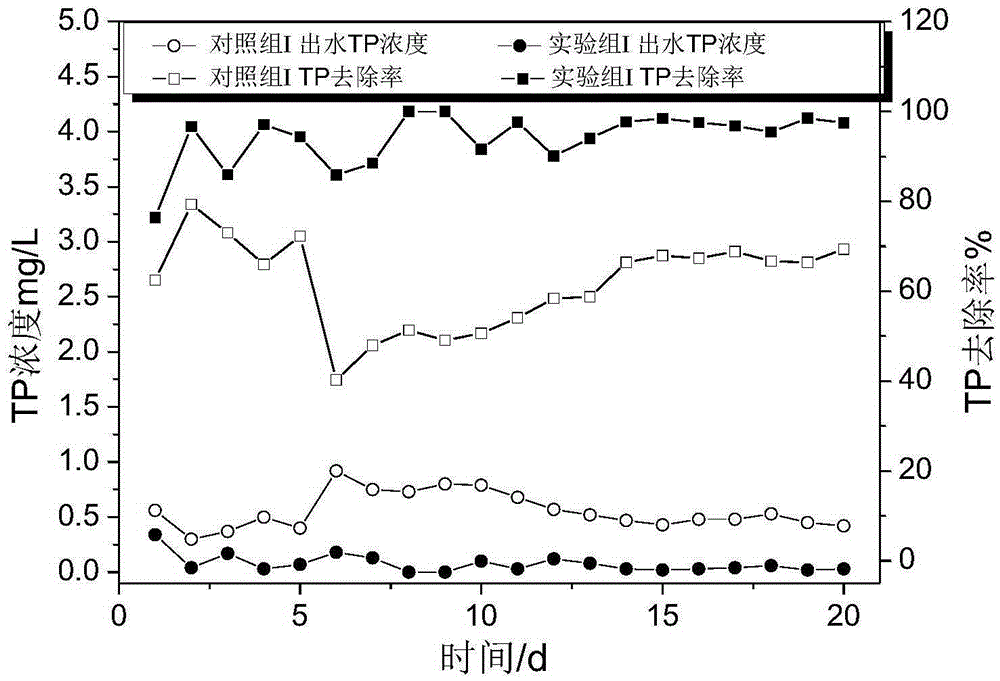

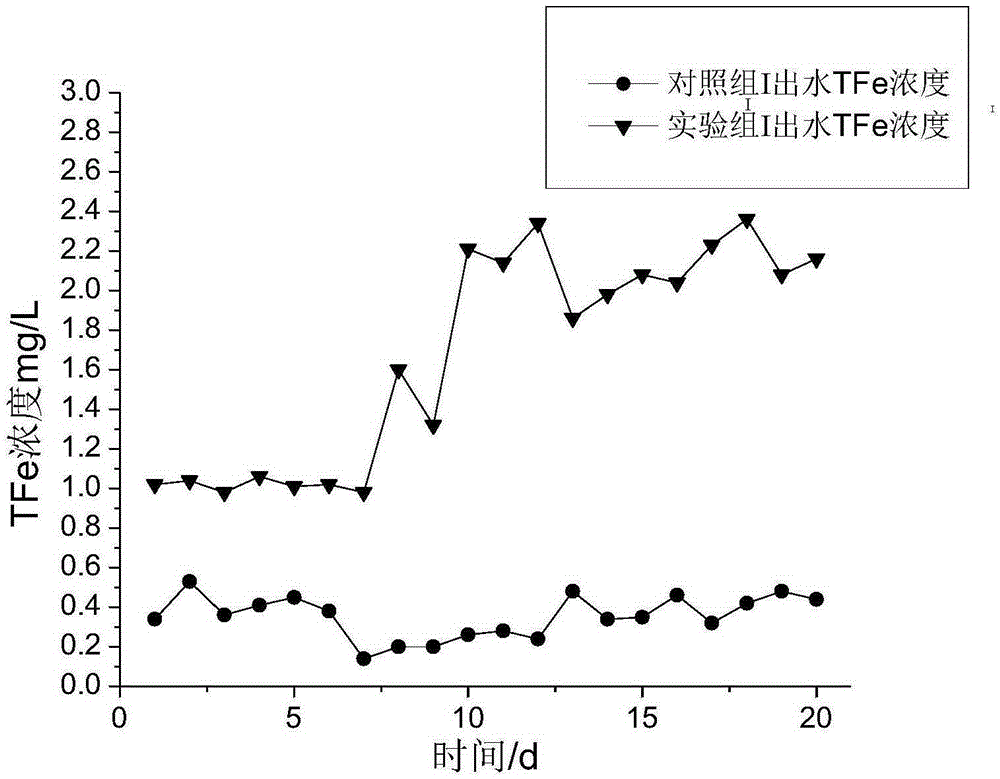

[0029] The test water is to add a certain amount of CH to tap water 3 COONa, KNO 3 and KH 2 PO 4 Artificial water distribution for simulating the secondary effluent of a sewage treatment plant. Control the concentration of TN and TP as follows: ρ(TN)=ρ(NO 3 -N)=35mg.L -1 , ρ(H 2 PO 4 -P)=1.3mg.L -1 . At the same time with 1mol L -1 of hydrochloric acid and 1mol·L -1 Sodium hydroxide solution is used to adjust the pH value of the distribution water to maintain at 6.8-7.2.

[0030]Experimental group I was filled with 150g of sponge iron particles with a particle size of 4-5mm and 100g of sulfur particles with a particle size of 2-3mm, which were mixed evenly and placed in a 500mL conical flask. The filler of the control group I used the same quality of sponge iron particles, and other control conditions were the same as those of the test group I. The hydraulic retention time HRT is 24h, the shaker speed is controlled at 64r / min, and the temperature is 28±2°C.

Embodiment 2

[0032] The experimental water is to add a certain amount of CH to tap water 3 COONa, KNO 3 and KH 2 PO 4 Artificial water distribution for simulating the secondary effluent of sewage treatment plant. Control the concentration of TN and TP as follows: ρ(TN)=ρ(NO 3 -N)=30mg.L -1 , ρ(H 2 PO 4 -P)=1.5mg.L -1 . At the same time with 1mol L -1 of hydrochloric acid and 1mol·L -1 Sodium hydroxide solution is used to adjust the pH value of the distribution water to maintain at 7.0-7.5.

[0033] The reactor adopts a plexiglass column with an inner diameter of 25 cm, a height of 0.6 m, and an effective volume of 8 L. The filler composition of experimental group II and control group II is shown in Table 1, wherein the particle size of sponge iron is 5-8mm, and the particle size of sulfur is 2-3mm. The hydraulic retention time HRT is controlled at 2h, 4h and 8h respectively.

[0034] Table 1 Reactor packing composition

[0035]

[0036] In the above implementation mode, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com