A kind of preparation method and application of small grain silicoaluminophosphate molecular sieve

A technology of silicoaluminophosphate and small crystal grains, which is applied in the direction of molecular sieve catalyst, molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc. It can solve the problems that have not been discovered and reported, and can improve the diffusion performance, The effect of reducing side reactions, simple preparation and catalytic process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

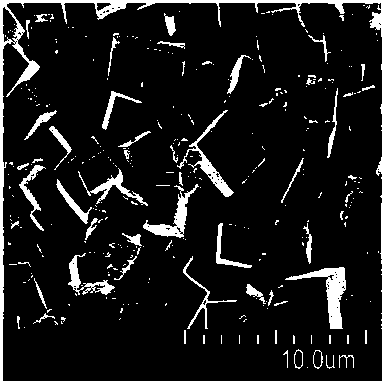

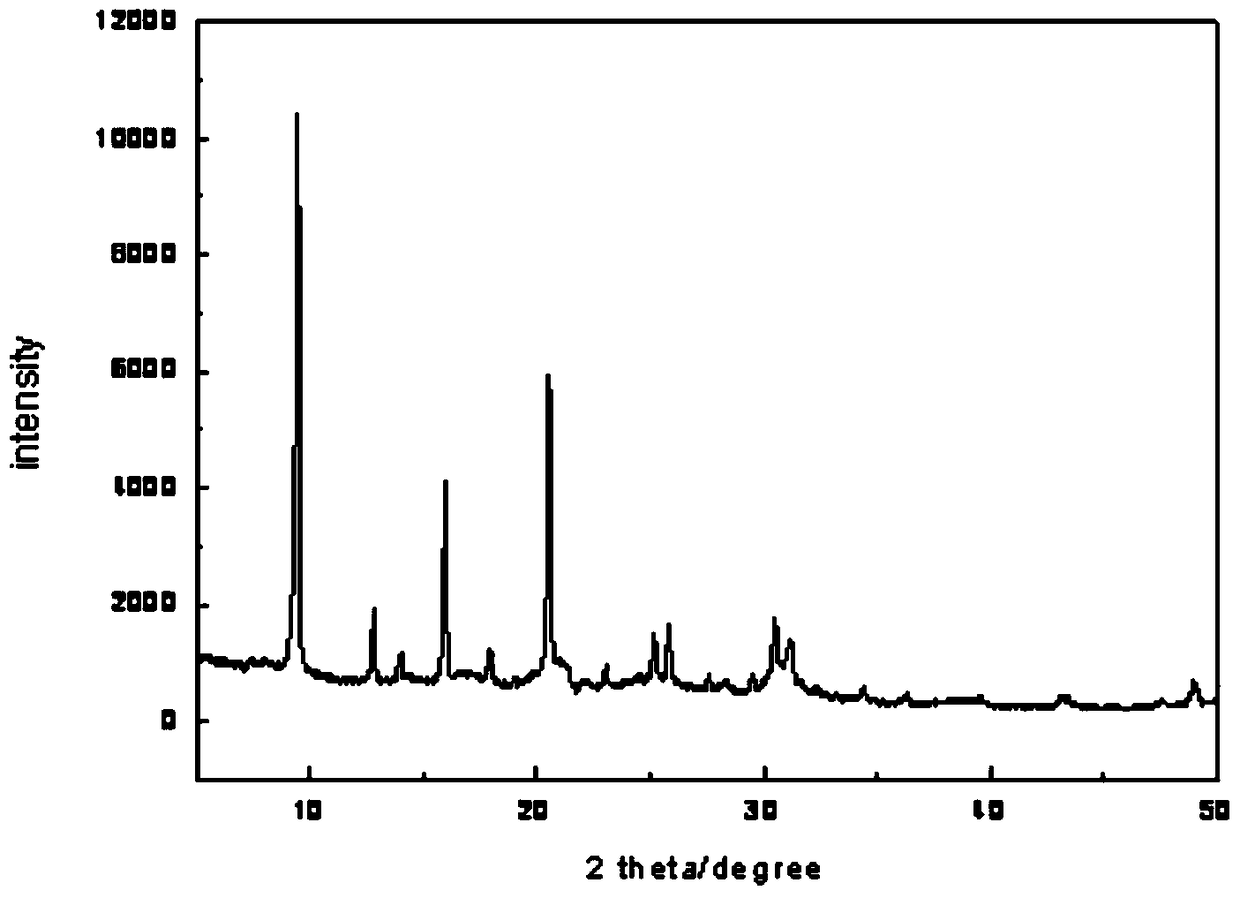

[0032] The preparation method of the small grain silicoaluminophosphate molecular sieve of the present embodiment comprises the following steps:

[0033] Step 1, according to the molar ratio Al 2 o 3 :P 2 o 5 : SiO 2 :TEAOH:TEA:H 2 O: PEG = 1.0: 0.5: 0.25: 0.1: 2.15: 50: 0.05, weigh pseudo-boehmite, orthophosphoric acid, silica sol, tetraethylammonium hydroxide, triethylamine, deionized water and polyethylene Ethylene glycol, then stir the weighed pseudo-boehmite, orthophosphoric acid, silica sol, tetraethylammonium hydroxide, triethylamine and deionized water evenly, then add polyethylene glycol, stir again Obtain an initial gel mixture, then place the initial gel mixture in a crystallization tank, conduct hydrothermal crystallization at a temperature of 200°C for 48 hours, and obtain a crystallization liquid after natural cooling;

[0034] Step 2. Filter, wash and dry the crystallization solution described in step 1 in sequence. The drying temperature is 120°C, and the d...

Embodiment 2

[0038] The preparation method of the small grain silicoaluminophosphate molecular sieve of the present embodiment comprises the following steps:

[0039] Step 1, according to the molar ratio Al 2 o 3 :P 2 o 5 : SiO 2 :TEAOH:TEA:H 2 O: PEG = 1.0: 1.0: 0.5: 0.2: 2.0: 80: 0.1, respectively weigh pseudo-boehmite, orthophosphoric acid, silica sol, tetraethylammonium hydroxide, triethylamine, deionized water and polyethylene Ethylene glycol, then stir the weighed pseudo-boehmite, orthophosphoric acid, silica sol, tetraethylammonium hydroxide, triethylamine and deionized water evenly, then add polyethylene glycol, stir again Obtain an initial gel mixture, then place the initial gel mixture in a crystallization tank, conduct hydrothermal crystallization at a temperature of 220°C for 50 hours, and obtain a crystallization liquid after natural cooling;

[0040] Step 2. Filter, wash and dry the crystallization solution described in step 1 in sequence. The drying temperature is 120°...

Embodiment 3

[0043] The preparation method of the small grain silicoaluminophosphate molecular sieve of the present embodiment comprises the following steps:

[0044] Step 1, according to the molar ratio Al 2 o 3 :P 2 o 5 : SiO 2 :TEAOH:TEA:H 2 O: PEG = 1.0: 0.8: 0.35: 0.15: 2.1: 65: 0.08, respectively weigh pseudo-boehmite, orthophosphoric acid, silica sol, tetraethylammonium hydroxide, triethylamine, deionized water and polyethylene Ethylene glycol, then stir the weighed pseudo-boehmite, orthophosphoric acid, silica sol, tetraethylammonium hydroxide, triethylamine and deionized water evenly, then add polyethylene glycol, stir again Obtain an initial gel mixture, then place the initial gel mixture in a crystallization tank, conduct hydrothermal crystallization at a temperature of 180°C for 45 hours, and obtain a crystallization liquid after natural cooling;

[0045] Step 2. Filter, wash and dry the crystallization solution described in step 1 in sequence. The drying temperature is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com