Engraving and milling machine for graphite rod production

An engraving and milling machine, graphite rod technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of easy cracking or breaking, easy breakage, low strength of graphite rods, etc., to improve processing accuracy, improve The effect of moving precision and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

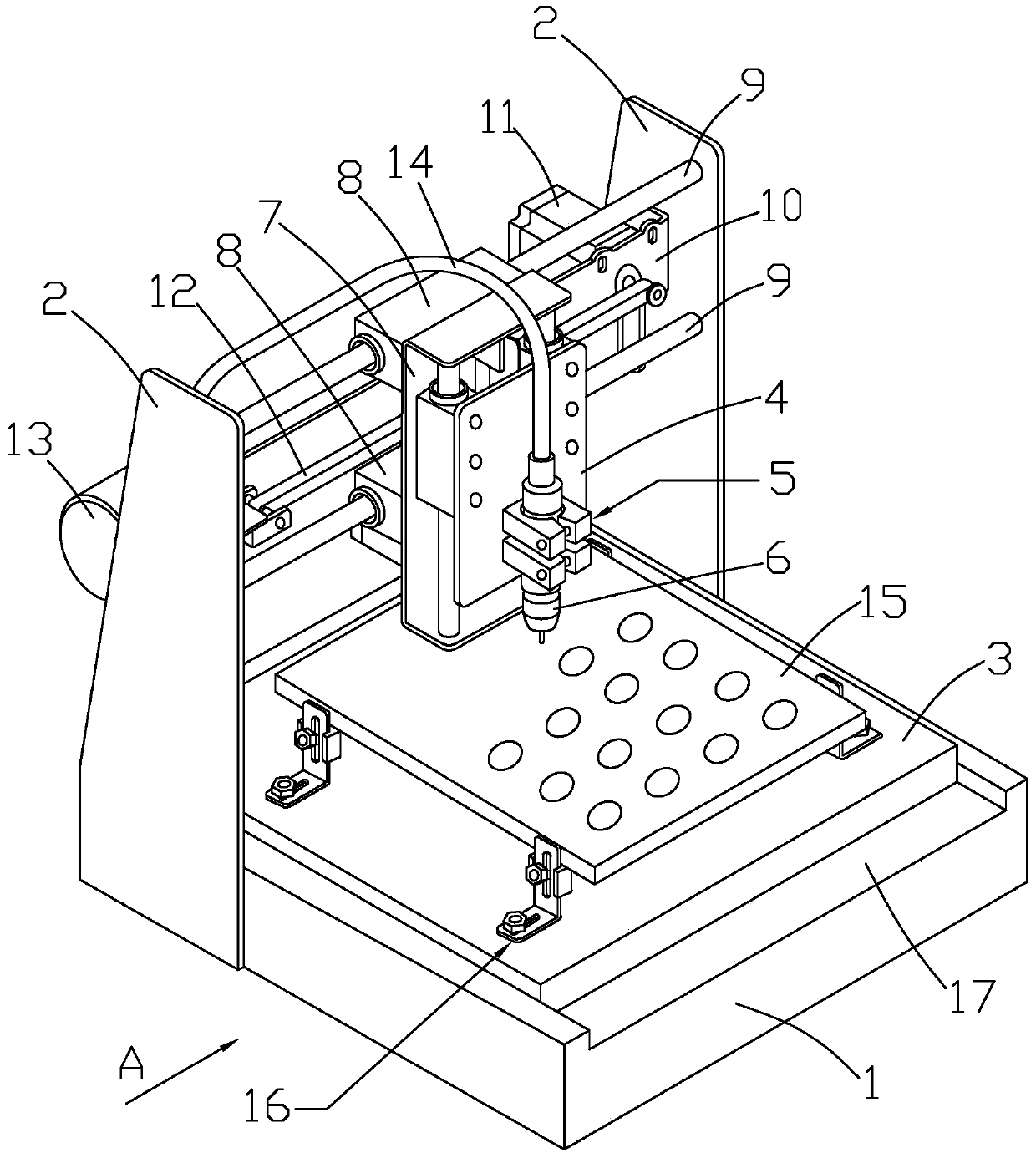

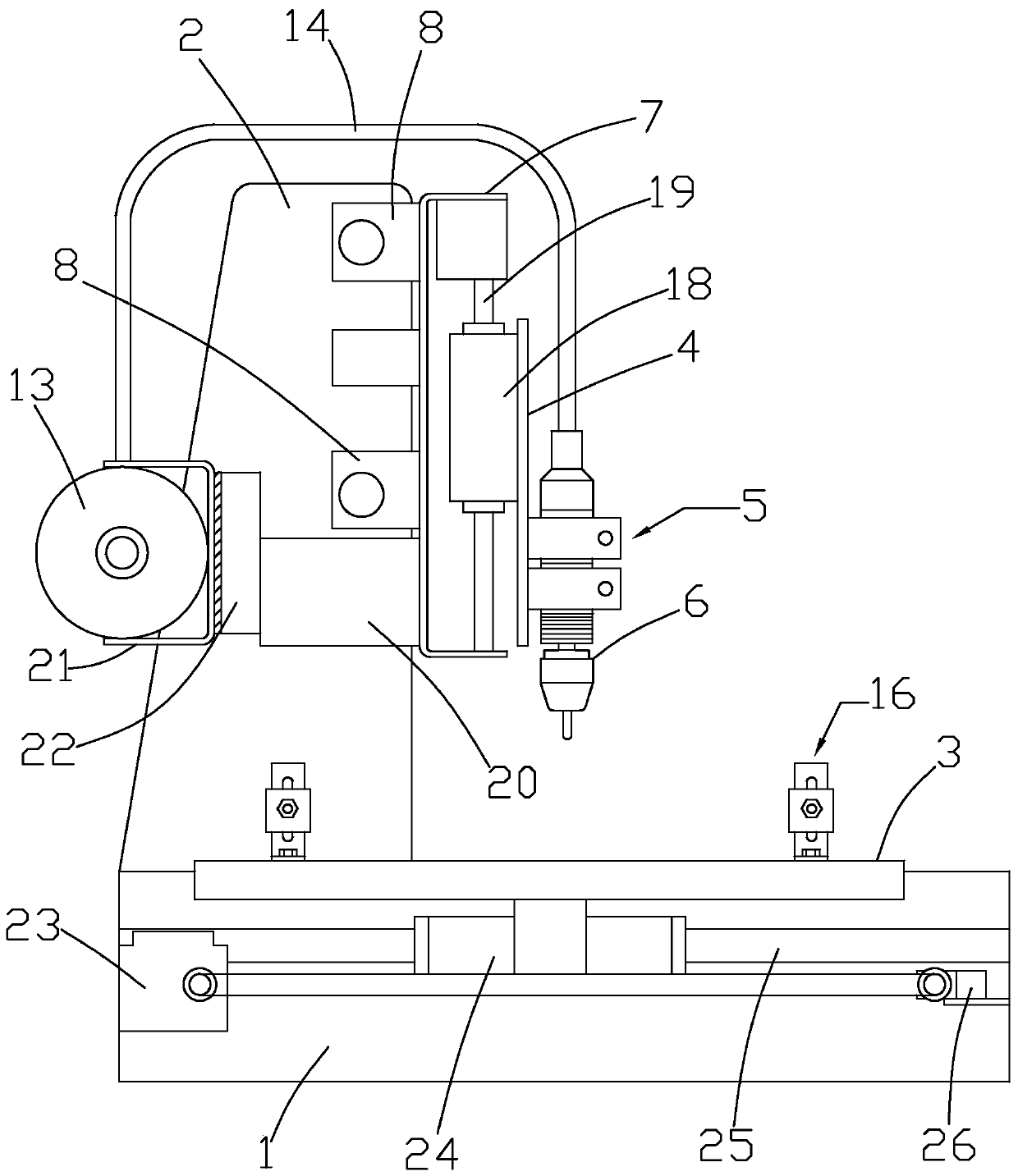

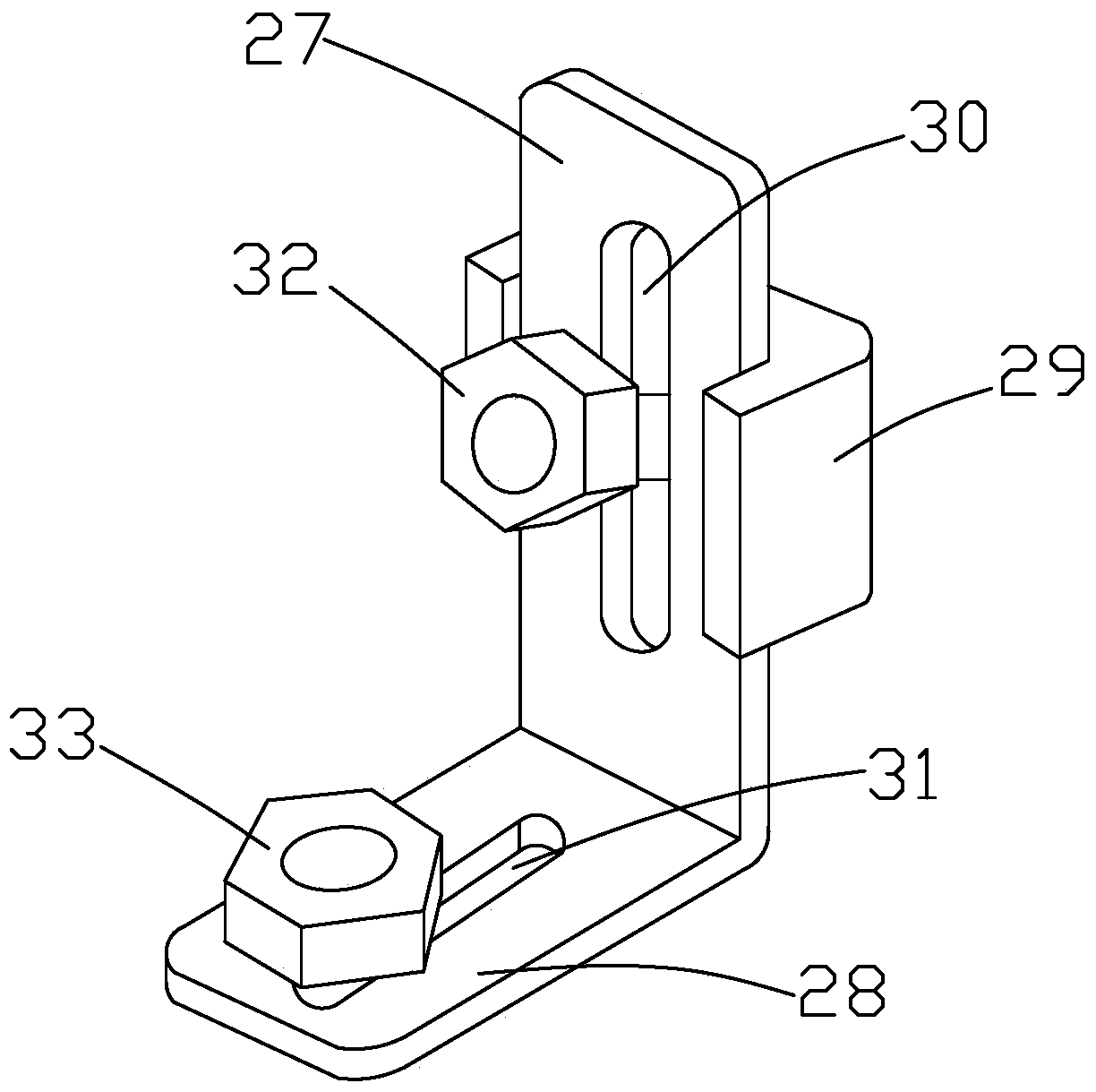

[0028] Such as Figure 1 to Figure 5As shown, it is an engraving and milling machine for the production of graphite rods of the present invention. The engraving and milling machine includes a machine base 1, a horizontal moving table 3, a support plate 2, a moving device and an engraving and milling mechanism, and the top surface of the machine base 1 A card slot 17 is provided, and the horizontal moving platform 3 is limited in the card slot 17. The horizontal moving platform 3 is connected to the base 1 through a driving mechanism, and the driving mechanism includes a second motor 23, a third slider 24, and a second horizontal slide rail 25 And stretching block 26, stretching block 26 is positioned at the opposite side of second motor 23, is connected by conveyor belt between second motor 23 and stretching block 26, and second horizontal slide rail 25 is positioned at second motor 23 and stretching block 26, the horizontal moving platform 3 is connected to the second horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com