Plasma water bed cutting platform assembly

A cutting platform and plasma technology, applied in plasma welding equipment, separation methods, filtration and separation, etc., can solve the problems of poor discharge of fine powder on the cutting platform, increase material cost and manufacturing cost, increase labor intensity of workers, etc., and achieve structural Simple, reduces the difficulty of disassembly and assembly, and has the effect of rapid slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

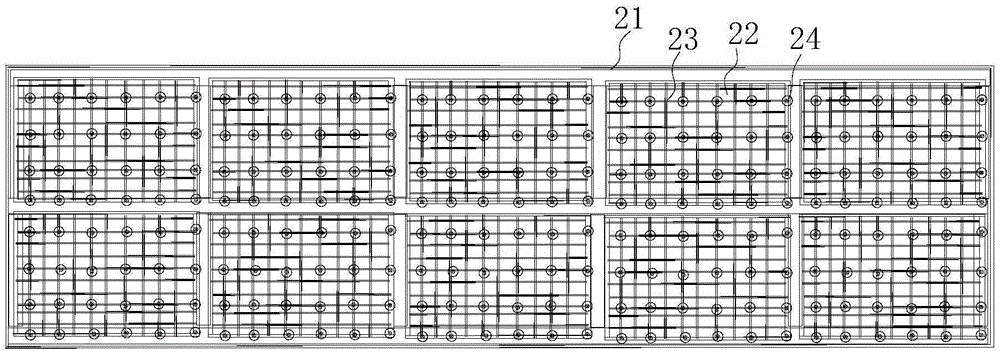

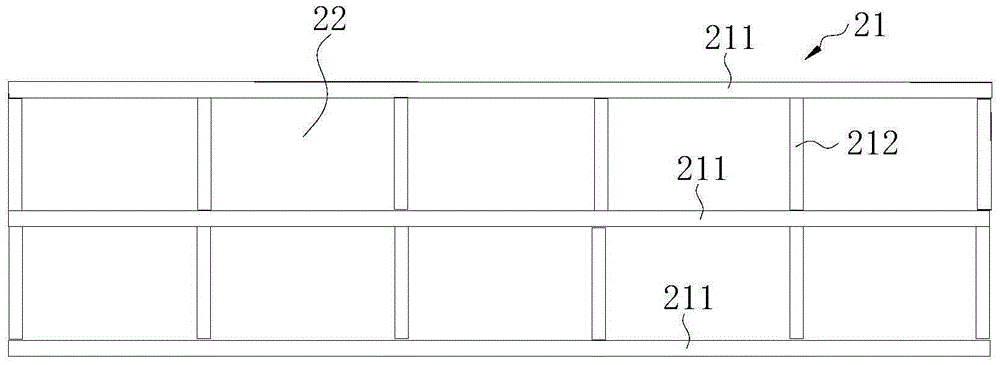

[0034] Such as Figures 1 to 5As shown, in the first embodiment of the present invention, the plasma water bed cutting platform assembly includes a pool 1, a support platform 2, a water baffle 3 and a dust hopper 4, and a double air inlet device and a double exhaust device are arranged in the water pool 1, The support platform 2 is installed obliquely above the pool 1, the water baffle 3 is arranged between the pool 1 and the support platform 2, one end of the water baffle 3 is connected with the dust hopper 4, and the dust hopper 4 is arranged between the support platform 2 and the pool 1 and is located at the inclined lower end of the support platform 2, there is a gap 5 between the dust hopper 4 and the side wall of the pool 1, the support platform 2 includes a frame 21, and a plurality of instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com