Continuous type drilling equipment for front supports of safety frames of forklifts

A technology of processing device and drilling device, applied in positioning device, metal processing, boring/drilling and other directions, can solve the problems of long process flow, low work efficiency, waste of human resources, etc., and achieve good drilling processing effect, Simple structure and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

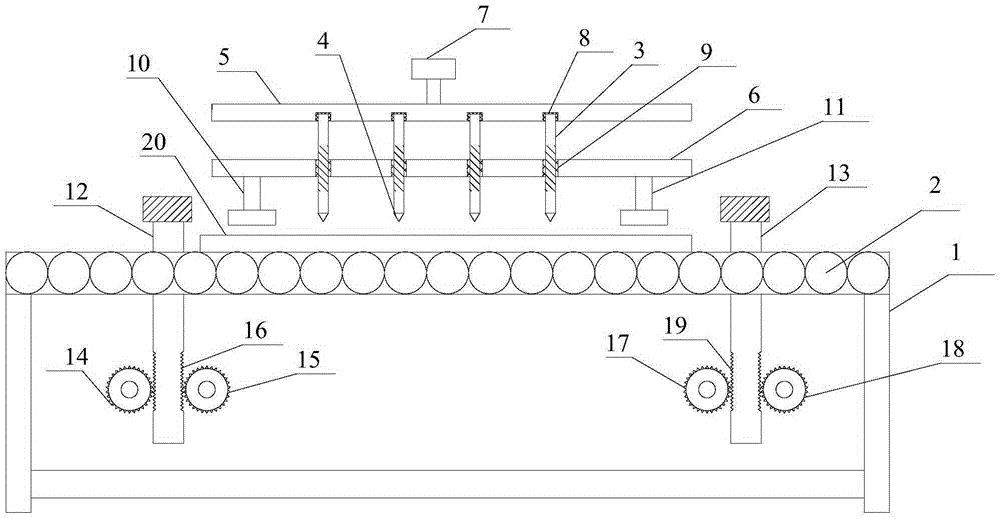

[0021] refer to figure 1 , figure 2 , image 3 , Figure 4 , the present invention proposes a continuous forklift safety frame front support drilling device, including a workbench 1, a drilling device for drilling the front support 20, and a limiting device for hindering the movement of the front support 20, wherein :

[0022] Between the feed end and the discharge end of the workbench 1 is provided a set of conveying rollers 2 for conveying the front support 20 .

[0023] In this embodiment, the drilling device is located above the conveying roller group 2, and the drilling device includes a first mounting frame 5, a second mounting frame 6, a third driving device 7, and a drilling unit for drilling the front support 20. And the fixing unit for fixing the front support 20, the drilling unit includes a plurality of drill rods 3 arranged side by side along the conveying direction of the conveying roller group 2, and the drill rods 3 are provided with a drill bit 4 near the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com