Concentric-circular-arc-curve-arrangement micro-lens array light-equalization plate and manufacturing method thereof

A micro-lens array and concentric arc technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of low production precision of light homogenizers, low light uniformity, poor light guide stability, etc. Uniformity, dimensional accuracy and precise shape accuracy guaranteed results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention is not limited to the range indicated by the examples.

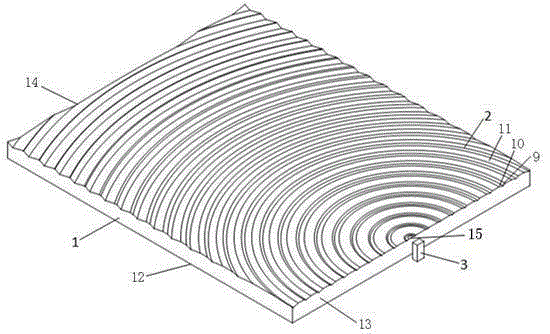

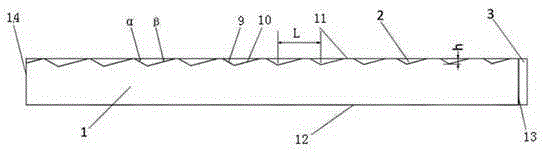

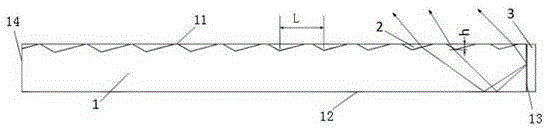

[0029] Such as figure 1 As shown, a microlens array homogenizing plate arranged in a concentric arc curve includes a single-sided side-entry acrylic plate 1, the lower surface of the acrylic plate 1 is a reflective surface 12, and a mirror reflective sticker is pasted on it. It is the light exit surface 11, and the side is the light incident surface 13 for placing the LED light source 3. A single LED light source 3 is placed at the midpoint of the light incident surface 13 of the acrylic plate 1. The LED light source 3 is facing the light incident surface 13, and is in line with the light incident surface The distance between the light surface 13 is 500-1000 μm. The light-emitting surface 11 is engra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com