Condenser safety diaphragm plate for detecting trace leakage

A condenser and micro-quantity technology, applied in the direction of measuring the increase and decrease rate of fluid, steam/steam condenser, liquid tightness measurement using liquid/vacuum degree, etc., can solve the problem of steam turbine device efficiency, power influence, safety film Problems such as bulging, puncture or puncture not touching, etc., to achieve the effect of efficient and safe equipment work, prevention of sharp instrument stabbing, and more efficient equipment work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

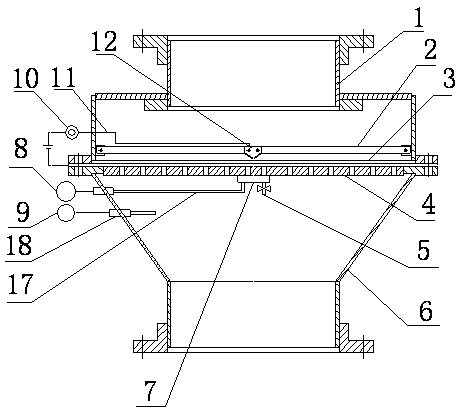

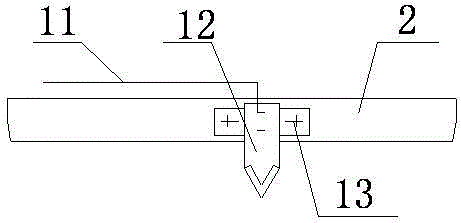

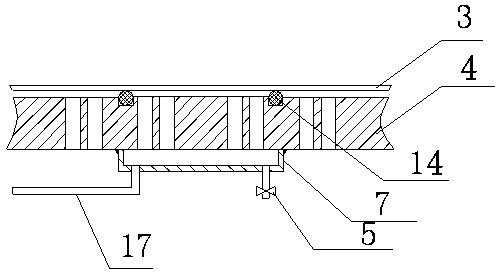

[0033] Such as figure 1 As shown, a condenser safety template for detecting trace leaks includes an upper shell 1 communicating with the atmosphere, a lower shell 6 for communicating with the inner cavity of the condenser, and the lower shell 6 and the end surface of the upper shell 1 For docking, a safety diaphragm 3 is provided between the lower housing 6 and the upper housing 1 to isolate the chambers of the upper and lower housings. Such as figure 2 As shown, a sharp 12 is fixed above the safety diaphragm 3 , a beam 2 is fixed on the upper housing 1 , the sharp 12 is fixed in the center of the beam, and an insulating layer 13 is arranged between the beam 2 and the sharp 12 . Both the safety diaphragm 3 and the sharps 12 are made of metal, and the tip of the sharps 12 points to the safety diaphragm 3 and keeps a certain distance from the safety diaphragm 3; A through hole for connecting the upper and lower spaces is arranged on the top, and the edge of the supporting ori...

Embodiment 2

[0038] The difference from Example 1 is:

[0039] like Figure 4 As shown, the supporting orifice plate is composed of a flange 19 provided with a grid 16 and a punching plate 15 arranged on the flange. like Figure 5 As shown, the sampling chamber is set in the middle of the flange, several grilles are connected between the sampling chamber and the flange, and a sealing ring is set between the port of the sampling chamber and the punching plate. It plays a certain supporting role for the safety template, and the gas cannot enter the sampling chamber through the gap between the two. Unless the template bulges and there is a gap between the two, the gas in the lower shell will enter the sampling chamber. The perforated plate is made of stainless steel.

[0040] In addition, if it is inconvenient to use pipelines to communicate with the sampling chamber and the lower casing, it is also possible to arrange sensitive pressure sensors in the sampling chamber 7 and the lower casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com