Preparation method of orderly nanofiber membrane based on bacterial cellulose

A technology of bacterial cellulose membrane and bacterial cellulose, which is applied in the field of preparation of ordered nanofiber membranes, can solve problems such as influence and lack of antibacterial properties, and achieve the effects of expanding application fields, easy operation, and superior antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

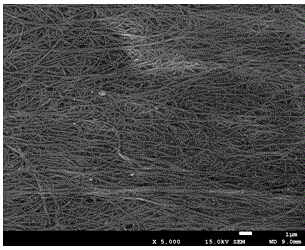

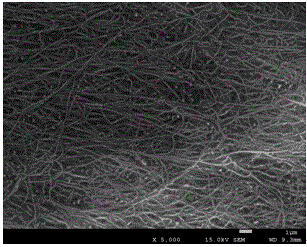

Image

Examples

Embodiment 1

[0026] Prepare 100 mL of seed culture with yeast extract (5 g / L), glucose (5 g / L), potassium dihydrogen phosphate (1 g / L), magnesium sulfate heptahydrate (15 g / L) and peptone (5 g / L) respectively base and 200 mL of fermentation medium. Put the seed medium and fermentation medium into a sterilizing pot at a temperature of 121°C and a pressure of 0.1MPa, and sterilize for 20 minutes. After the culture medium is cooled, add ethanol (20mL / L). The activated Acetobacter xylinum was inoculated into the seed medium, and cultured in a shaker at 28° C. and 160 rpm / min for 24 hours. According to the inoculum amount of 6%, inoculate the seed culture solution into the fermentation medium and shake it well to mix it evenly, and then culture it statically at 28°C for 7 days to obtain the bacterial cellulose film. Rinse the residues on the surface of bacterial cellulose with deionized water, soak in 0.1M NaOH solution, heat and stir at 80°C for 1 h, then adjust the pH to 7.0 with acetic acid...

Embodiment 2

[0028] Prepare 100 mL of seeds with yeast extract (6 g / L), glucose (6 g / L), potassium dihydrogen phosphate (0.8 g / L), magnesium sulfate heptahydrate (18 g / L) and peptone (6 g / L) respectively medium and 200 mL of fermentation medium. Put the seed medium and fermentation medium into a sterilizing pot at a temperature of 121°C and a pressure of 0.1MPa, and sterilize for 20 minutes. After the culture medium is cooled, add ethanol (10mL / L). The activated Acetobacter xylinum was inoculated into the seed medium, and cultured in a shaker at 30° C. and 160 rpm / min for 24 hours. According to the inoculation amount of 8%, the seed culture solution was inoculated into the fermentation medium, shaken sufficiently to mix evenly, and then cultured statically at 30°C for 7 days to obtain the bacterial cellulose film. Rinse the residues on the surface of bacterial cellulose with deionized water, soak in 0.2M NaOH solution, heat and stir at 85°C for 1 h, then adjust the pH to 7.0 with acetic a...

Embodiment 3

[0030] Prepare 100 mL of seed culture with yeast extract (5 g / L), glucose (5 g / L), potassium dihydrogen phosphate (1 g / L), magnesium sulfate heptahydrate (15 g / L) and peptone (5 g / L) respectively base and 200 mL of fermentation medium. Put the seed medium and fermentation medium into a sterilizing pot at a temperature of 121°C and a pressure of 0.1MPa, and sterilize for 20 minutes. After the culture medium is cooled, add ethanol (20mL / L). The activated Acetobacter xylinum was inoculated into the seed medium, and cultured in a shaker at 32° C. and 160 rpm / min for 24 hours. According to the inoculation amount of 8%, the seed culture solution was inoculated into the fermentation medium, shaken sufficiently to mix evenly, and then cultured at 32°C for 10 days to obtain the bacterial cellulose film. Rinse the residues on the surface of bacterial cellulose with deionized water, soak in 0.15M NaOH solution, heat and stir at 75°C for 2h, then adjust the pH to 7.0 with acetic acid, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com