A kind of manufacturing method of permanent magnet ferrite

A technology of permanent magnet ferrite and manufacturing method, applied in the direction of magnetism of inorganic materials, etc., can solve the problems of easy cracking, poor product performance, etc., and achieve the effects of not easy to agglomerate, improve magnetic field orientation, and narrow particle size distribution range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

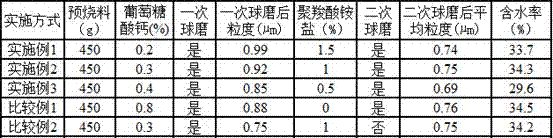

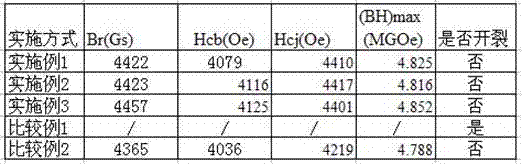

Embodiment 1

[0020] Embodiment 1: the permanent magnet ferrite pre-fired material is passed through 300 mesh sieve screening processes, get the permanent magnet ferrite pre-fired material 450g that cannot pass through the hole purpose, and the following mass percentages are all based on the quality of the 450g permanent magnet pre-fired material, Add 0.4% SiO2 and 0.6% CaCO3 in the form of mass percentage to obtain a mixture; add 0.2% calcium gluconate in the mixture to carry out wet ball milling, and the diameter of steel balls in wet ball milling D1=6.6 µm, grind for 12 hours to obtain a primary grinding slurry with an average particle size of 0.85-1.0 μm. After taking out the primary grinding slurry, add 1.5% polycarboxylate ammonium salt and carry out wet ball milling. The polycarboxylate ammonium salt The carbon chain length is 5-10 C, the diameter of the steel ball in wet ball milling is D2=3µm, and the grinding time is 8 hours to obtain a secondary abrasive with an average particle s...

Embodiment 2

[0021] Embodiment 2: the mass percent of calcium gluconate is 0.3%, the mass percent of polycarboxylate ammonium salt is 1%, the magnetic field size of orientation setting is 12000GS, and the shaped body after setting is incubated at 115 ℃ for 1.25h, then heats up to Insulate at 450°C for 2.25h, then raise the temperature to 1223°C for 1.5h, and the rest of the steps are the same as in Example 1.

Embodiment 3

[0022] Embodiment 3: the mass percentage of calcium gluconate is 0.4%, the mass percentage of polycarboxylate ammonium salt is 0.5%, the magnetic field size of orientation setting is 14000GS, and the shaped body after setting is incubated at 130 ℃ for 1h, and then heated up to 500 ℃ for 2 hours, and then heated up to 1220 ℃ for 1 hour, and the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com