Rotary bottle blowing machine

A blow molding machine and frame technology, which can be applied to other household appliances, household appliances, applications, etc., can solve problems such as high processing difficulty, hidden safety hazards for debugging personnel, and disorderly arrangement of internal components of the rotary blow molding machine, etc., to achieve safety protection Level up, best visual effects, fast action effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

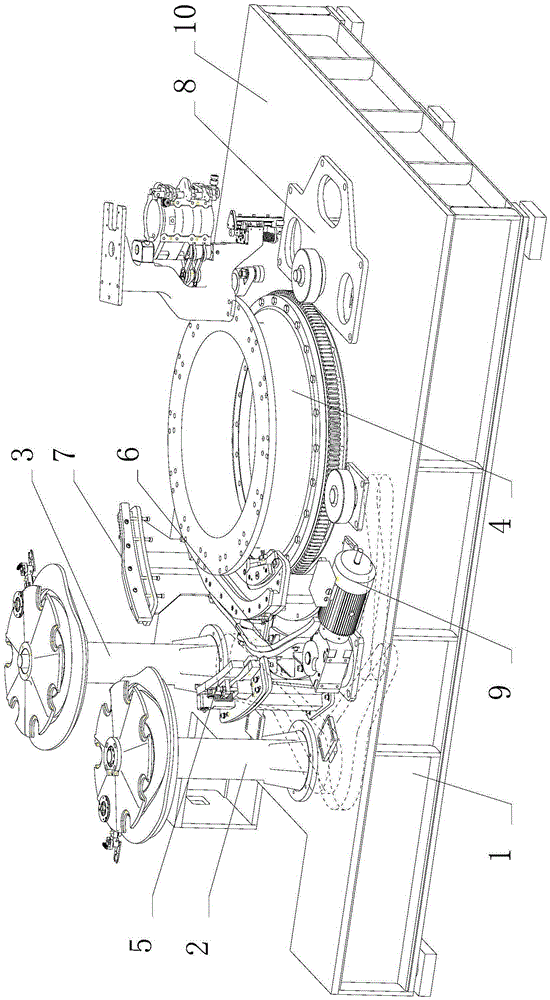

[0010] Such as figure 1 As shown, the rotary blow molding machine includes a frame 1, an embryo feeding manipulator part 2, a bottle outlet manipulator part 3, a rotating mold base, a locking guide rail part 5, a bottom mold guide rail part 6, an opening and closing mold guide rail part 7, and a brake part 8. Transmission system, motor 9. The bottom of frame 1 is provided with base plate 10, and this base plate 10 is separated and keeps a certain distance from the position of supporting force at the bottom of frame 1, that is, the feet of the adjustable machine, so that frame 1 is positioned between base plate 10 and adjustable machine feet. A larger area is created between the foot supports. The bottom plate 10 is a flat plate, and is provided with two large flat surfaces. The profile of the bottom plate 10, that is, the outer contour formed on the aforementioned surfaces, is the same as the profile of the cross-section at the position where the bottom plate 10 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com