Glass substrate, liquid crystal display panel and liquid crystal display device

A technology for glass substrates and display areas, applied in instruments, nonlinear optics, optics, etc., can solve problems such as lower yield, poor product functionality, and development of large cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

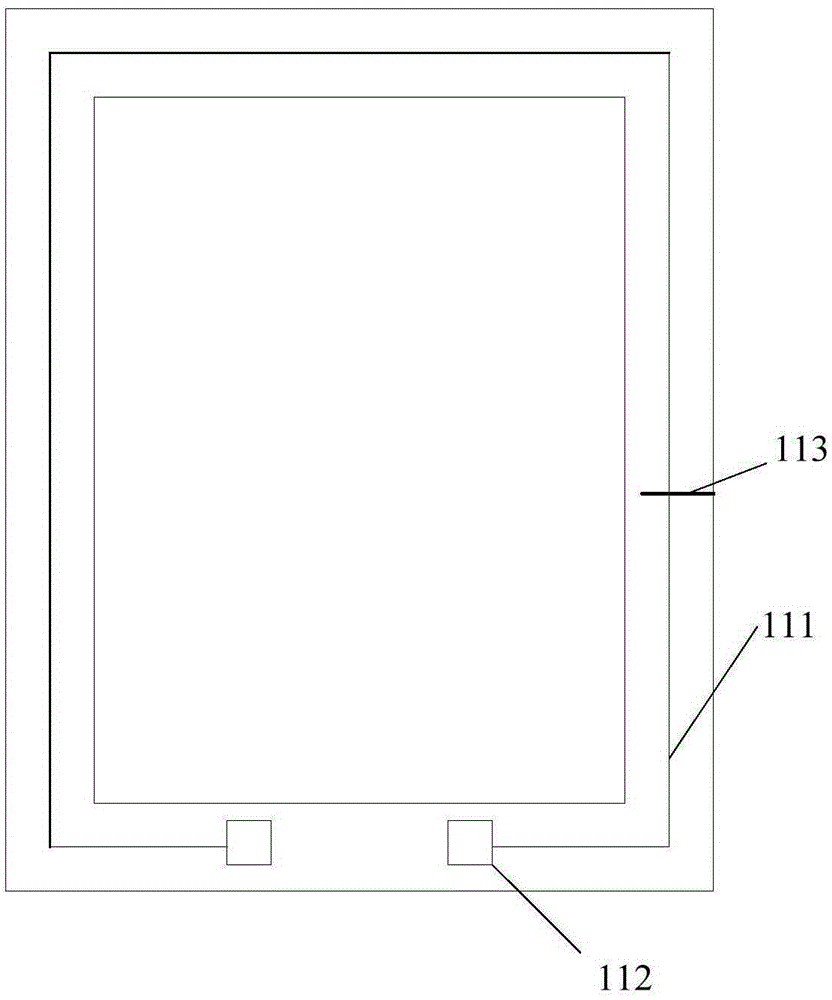

[0021] Figure 4 A schematic structural view of a glass substrate provided in Embodiment 1 of the present invention, such as Figure 4 As shown, the glass substrate includes a display area 410 and a non-display area 420 , and the non-display area 420 of the glass substrate is provided with a crack detection wire 430 .

[0022] The crack detection wire 430 is located on at least one side of the glass substrate, and is divided into at least two sections along the extension direction of the crack detection wire 430, and the two adjacent crack detection wires along the extension direction are electrically connected, and each section The crack detection wire 430 is composed of at least two parallel wire units 431 . At least one wire unit 431 of each segment of the crack detection wire 430 is located outside the maximum deviation of cutting.

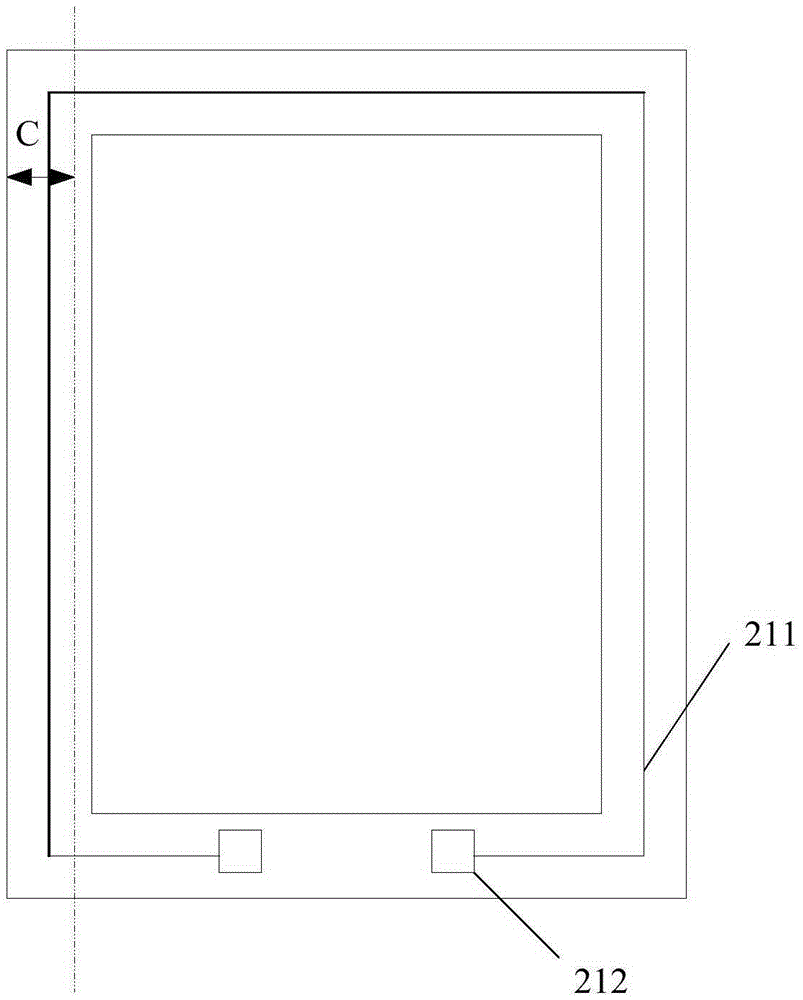

[0023] see Figure 5 , where the maximum cutting deviation C is the difference between the allowed actual cutting line 521 and the ideal c...

Embodiment 2

[0040] Figure 6 It is a schematic structural diagram of a glass substrate provided in Embodiment 2 of the present invention.

[0041] In the embodiment of the present invention, the crack detection wires located on the same side of the glass substrate can be divided into at least two sections, wherein, Figure 6 What is shown is the situation where the crack detection wires 610 on the left and right sides are divided into two sections, wherein each crack detection wire 610 includes three wire units 611 .

[0042] In addition, for each wire unit 611 on the same section of crack detection wire 610, its resistance value can be the same as that shown in the first embodiment above, or it can be different. Specifically, the resistance value of each wire unit 611 located in the same section can be It gradually increases from the edge of the glass substrate inward.

[0043] Moreover, the resistance value of each wire unit 611 can be set to be different by setting any one or several...

Embodiment 3

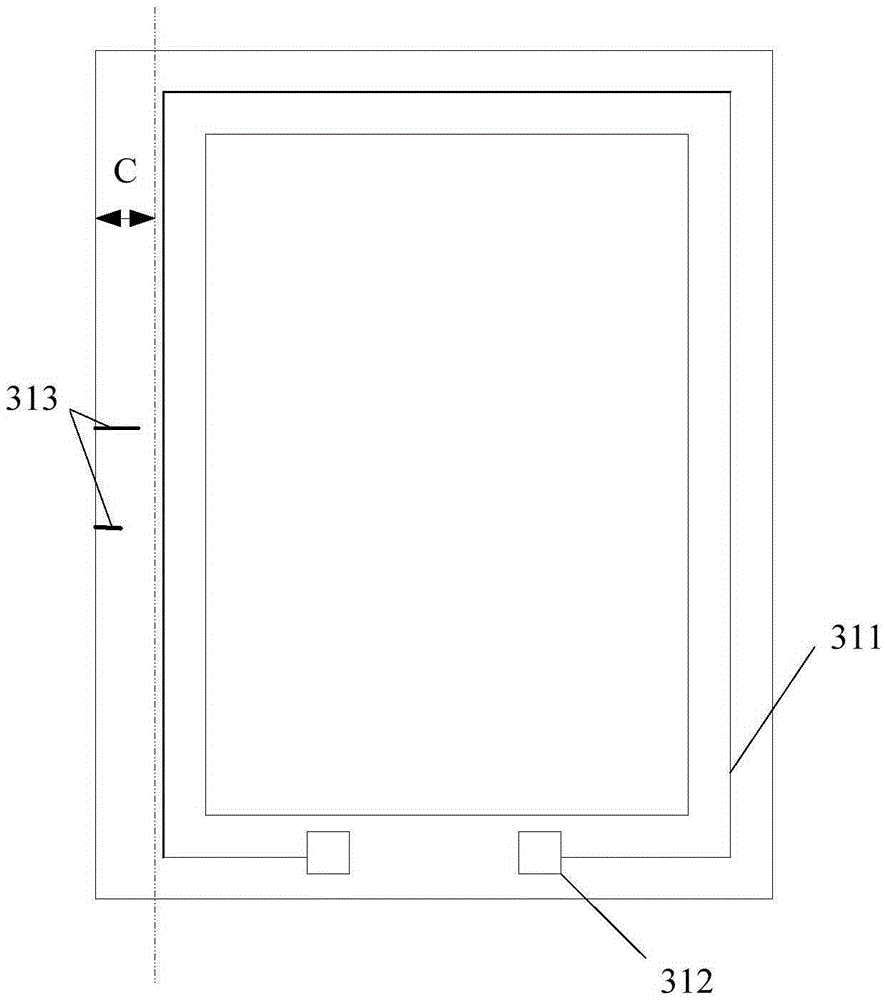

[0056] Figure 7 It is a schematic structural diagram of a glass substrate provided in Embodiment 3 of the present invention. The difference from the above embodiment is that the crack detection wire on the upper side of the glass substrate is divided into two sections.

[0057] Such as Figure 7 As shown, the crack detection wire 710 is divided into 6 sections along the extension direction of the crack detection wire 710 , and each crack detection wire 710 is composed of 3 parallel wire units 711 . Wherein the inner wire unit of each crack detection wire 710 is located outside the maximum cutting deviation C, assuming that the resistance value of each parallel wire unit 711 is from the outer ring to the inner ring in order: the outer wire unit is a / 3, and the middle wire unit is a / 2, the inner wire unit is a.

[0058] Cracks and cutting conditions of the glass substrate are judged by calculating the total resistance of the crack detection wires, as follows:

[0059] (1) W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com