Novel integrated high-medium-pressure internal cylinder applied to supercritical steam turbine

A high-medium pressure and steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of increased heat consumption of units, low assembly efficiency, low flow efficiency of high-medium pressure, etc., to reduce heat consumption and improve efficiency , the effect of reducing steam leakage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

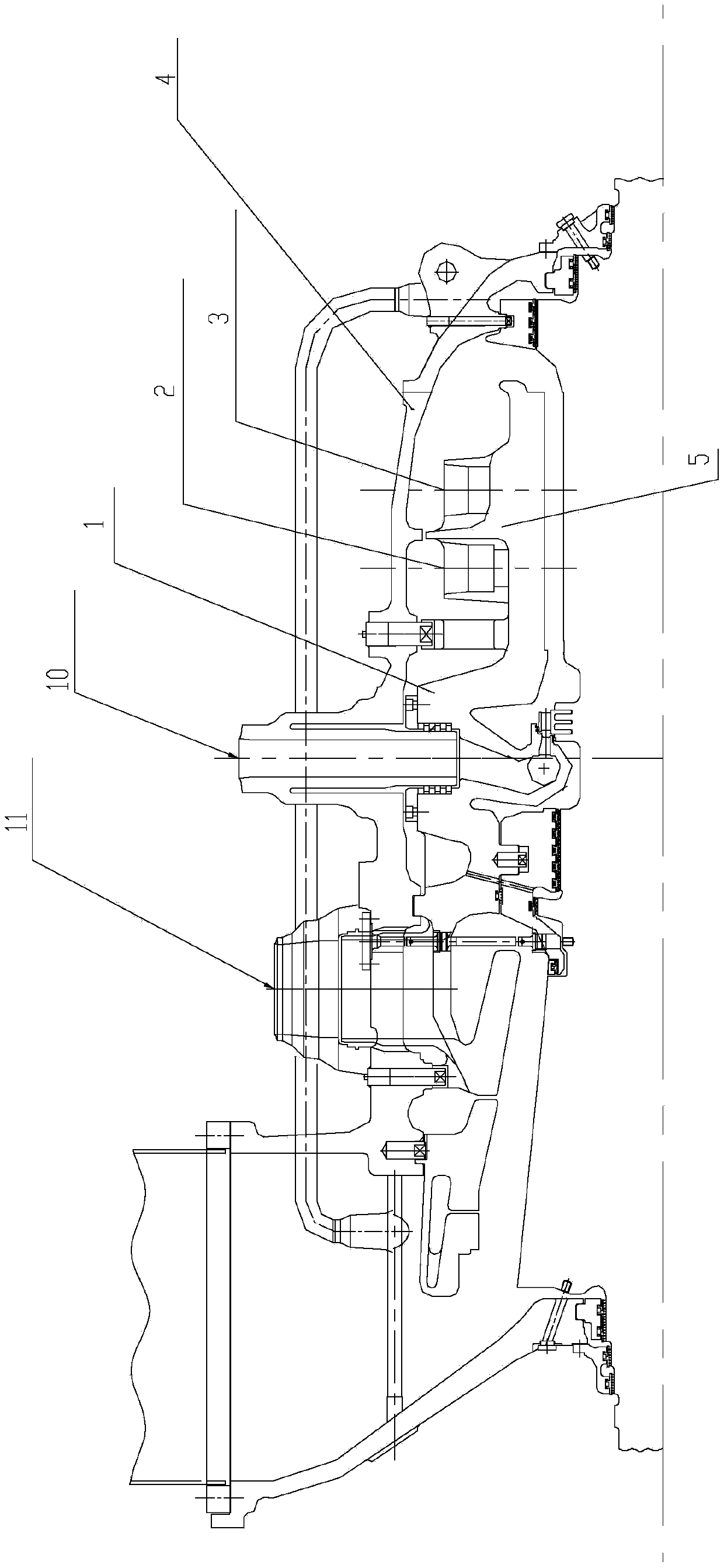

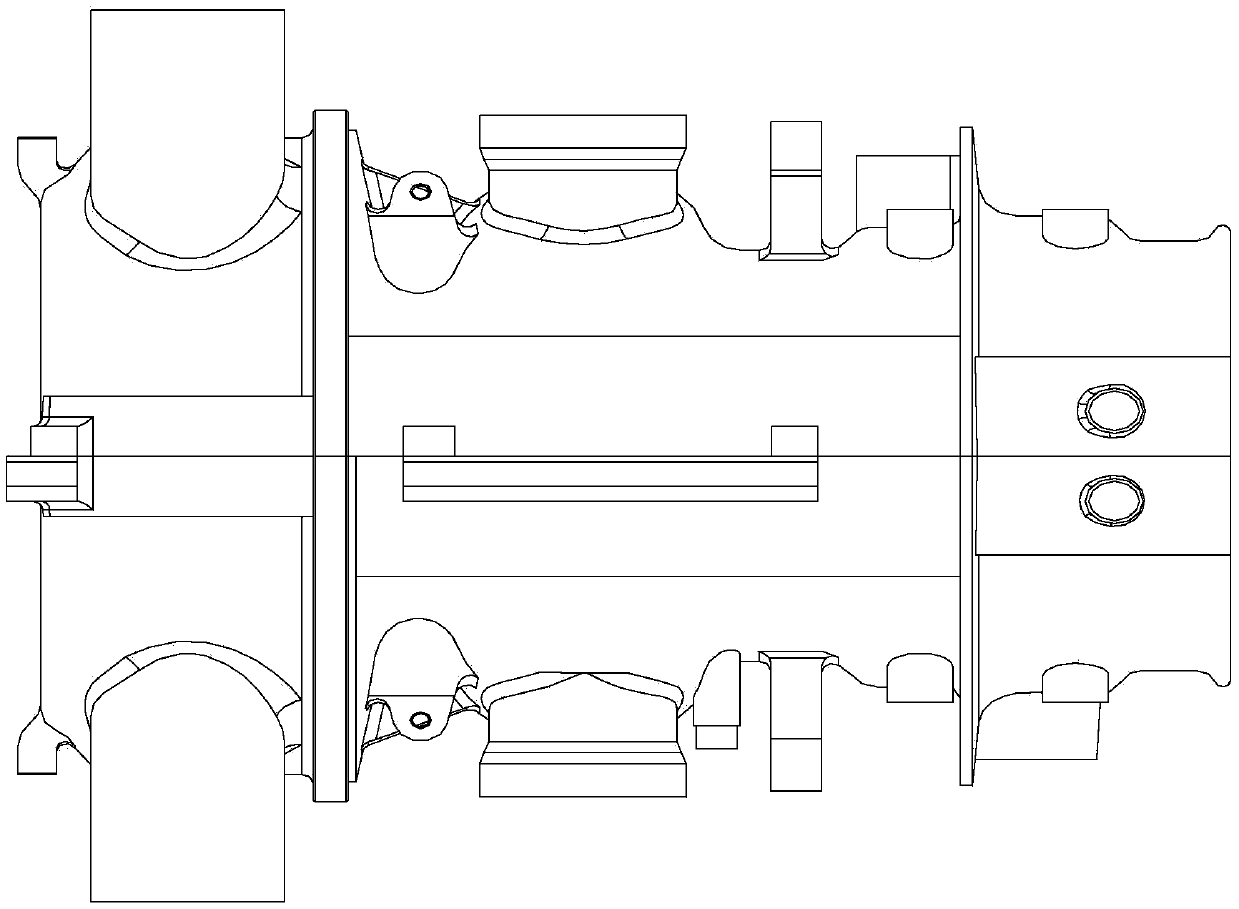

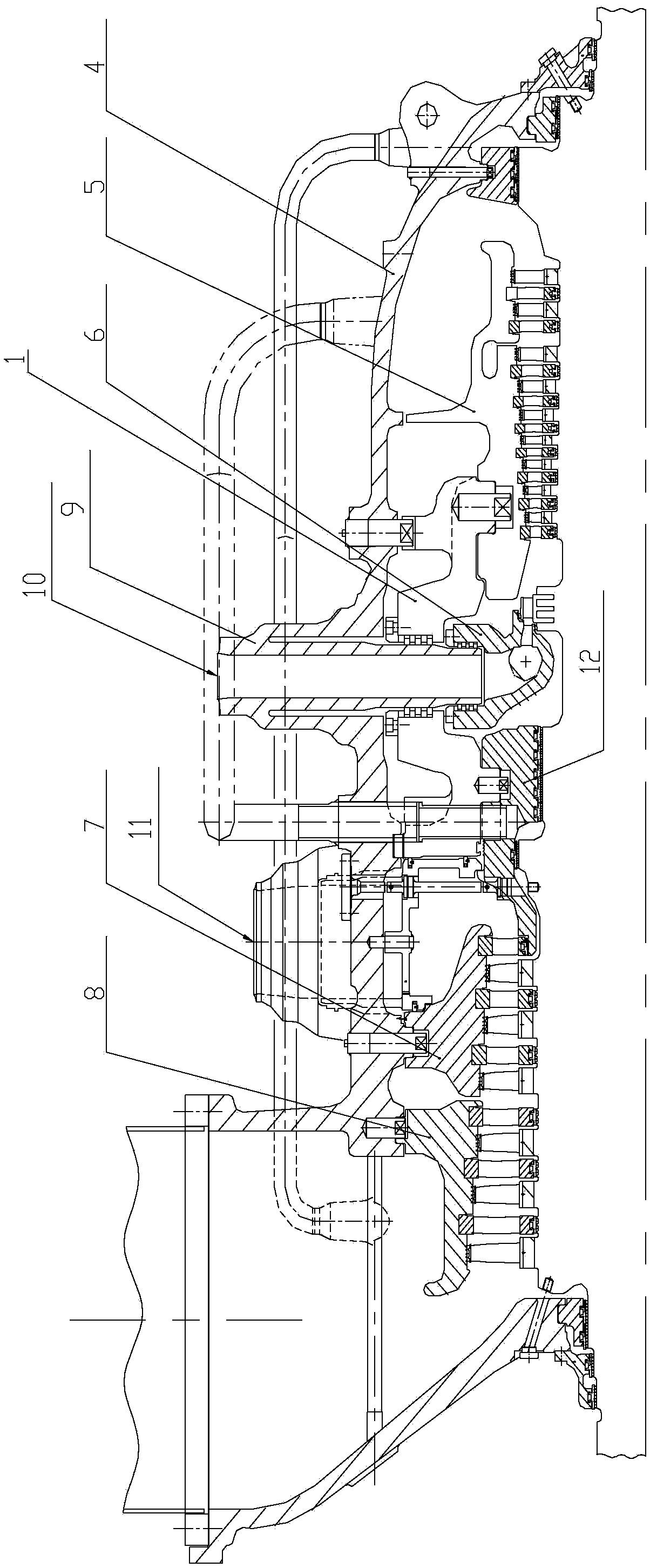

[0010] Specific implementation mode one: see Figure 1 to Figure 3 Describe this embodiment, a new type of overall high and medium pressure inner cylinder applied to supercritical steam turbines described in this embodiment, including high and medium pressure inner cylinder 1, high pressure partition sleeve 5 and medium pressure No. 1 partition sleeve 7, the The high and medium pressure inner cylinder 1, the high pressure partition sleeve 5 and the medium pressure No. 1 partition sleeve 7 are integrated, and the blades of the high pressure part are directly installed on the high and medium pressure inner cylinder 1.

[0011] The high and medium pressure inner cylinder is an integral casting structure, the blades of the flow part are directly fixed on the high and medium pressure inner cylinder, reducing the number of assembly parts, the structure is simple, the machining and installation are time-saving and labor-saving, and the unit structure is simple. The assembly between p...

specific Embodiment approach 2

[0012] Specific embodiment 2: This embodiment is a further limitation of a new type of overall high and medium pressure inner cylinder applied to supercritical steam turbines described in specific embodiment 1. In this embodiment, the high-pressure steam inlet and the medium-pressure steam inlet , No. 0 high-pressure heater extraction port 2, No. 1 high-pressure heater extraction port 3, high and medium pressure steam inlet side balance holes, and the partition groove are integrated into one piece.

[0013] This embodiment can further reduce the amount of steam leakage, improve the efficiency of the high and medium pressure parts, reduce the heat consumption of the unit, and improve the economy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com