Technology using vaccinium bracteatum plant dye for dyeing of black blue real silk

A technology of black rice leaves and plant dyes, which is applied in the field of blue-black silk dyeing technology, can solve the problem of single chromatogram, etc., and achieve the effect of simple extraction method, excellent cloth surface effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

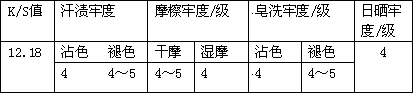

Image

Examples

Embodiment 1

[0020] In the present embodiment, the black rice leaf vegetable dyestuff is used for the technique of real silk dyeing, mainly comprises the following steps:

[0021] (1) Extraction of plant dyes from black rice leaves

[0022] Take fresh black rice leaves and wash them at room temperature, then wash them again with deionized water, dry the water on the surface of the leaves naturally, weigh them, cut the leaves of black rice leaves into small pieces of 5 mm × 10 mm with clean scissors, and divide them according to the size of the leaves and 60 ℃ mixed with deionized water at a mass ratio of 1:10 to 1:15 to make a slurry, leached in a shaking water bath at 50 to 60 ℃ for 2 to 3 hours, vacuum filtered, and took the filtrate for later use;

[0023] (2) Dyeing of blue-black silk

[0024] Wet the silk to be dyed which is half the mass of the leaves of black rice leaves in normal temperature water for 15 minutes, squeeze it dry, put it into the above standby filtrate with a bath r...

Embodiment 2

[0035] The process that the black rice leaf plant dye in the present embodiment is used for the dyeing of real silk mainly comprises the following steps:

[0036] (1) Extraction of plant dyes from black rice leaves

[0037] Take fresh black rice leaves and wash them at room temperature, then wash them again with deionized water, dry the water on the surface of the leaves naturally, weigh them, cut the leaves of black rice leaves into small pieces of 5 mm × 10 mm with clean scissors, and divide them according to the size of the leaves and 60 Mix with deionized water at a mass ratio of 1:12 at ℃ to make a slurry, extract in a shaking water bath at 60℃ for 2 to 3 hours, vacuum filter, and take the filtrate for later use;

[0038] (2) Dyeing of blue-black silk

[0039] Wet the silk to be dyed which is half the mass of the leaves of black rice leaves in normal temperature water for 10 minutes, squeeze it dry, put it into the above spare filtrate with a bath ratio of 1:20, the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com