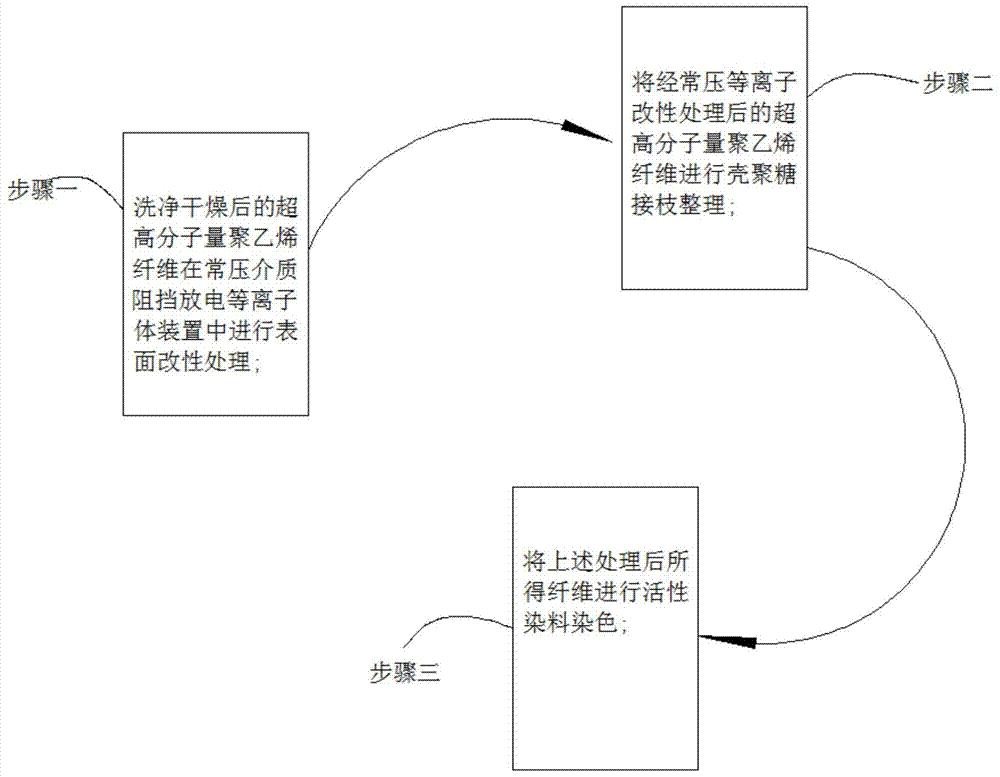

A method for dyeing after surface treatment of ultra-high molecular weight polyethylene fibers

A technology of polyethylene fiber and ultra-high molecular weight, which is applied in ultrasonic/sonic fiber treatment, fiber treatment, dyeing, etc., can solve the problems of difficult dyeing of ultra-high molecular weight polyethylene fiber, and achieve the solution of difficult dyeing, convenient operation, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

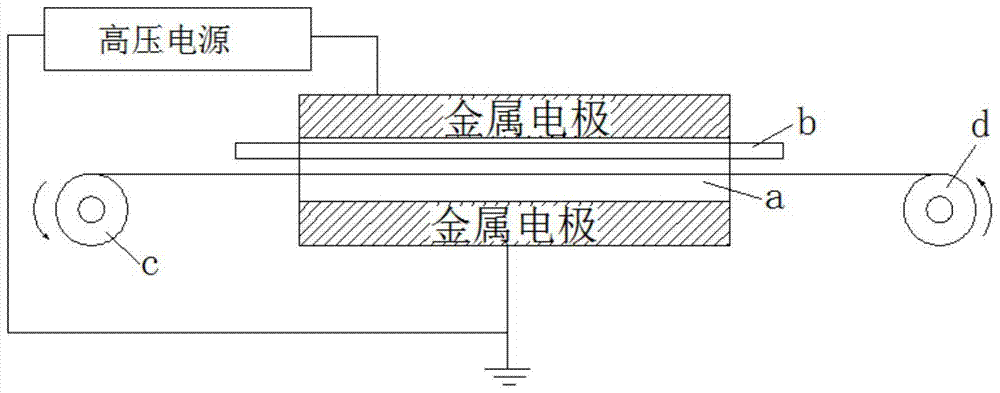

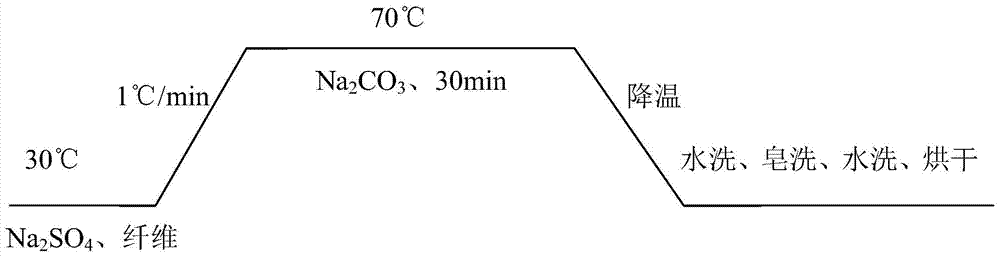

[0032] See attached image 3: the dyeing method of ultra-high molecular weight polyethylene fiber of the present invention after surface treatment, at first will carry out normal pressure dielectric barrier discharge plasma continuous treatment with the fiber of acetone cleaning 30min back drying, and plasma treatment atmosphere is Ar and O 2 Mixed gas, the flow rate of Ar gas is 1L / min, O 2 The flow rate is 0.1L / min, the processing power is 4Kw, and the processing time is 80s. After that, the fibers after plasma surface modification are grafted with chitosan. The molecular weight of chitosan is about 50,000. The density is about 90%, chitosan is prepared into chitosan solution with 2% acetic acid solution, the mass fraction of chitosan solution is 0.5%, the temperature of grafting is 40°C, the time of grafting is 0.5h, and the grafting time is 0.5h. The bath ratio is 1:40. The grafted fibers are washed with deionized water, dried, and then dyed. The dyeing agent is 3% (o.w....

Embodiment 2

[0034] See attached Figure 4 : the dyeing method of ultra-high molecular weight polyethylene fiber of the present invention after surface treatment, at first will carry out normal pressure dielectric barrier discharge plasma continuous treatment with the fiber of acetone cleaning 30min back drying, and plasma treatment atmosphere is Ar and O 2 Mixed gas, the flow rate of Ar gas is 1L / min, O 2 The flow rate is 0.1L / min, the processing power is 4kw, and the processing time is 100s. After that, the fiber after plasma treatment is grafted with chitosan. The molecular weight of chitosan is about 50,000, and the degree of deacetylation is about 90. %, chitosan adopts 2% acetic acid solution to prepare chitosan solution, the mass fraction of chitosan solution is 0.7%, the temperature of grafting is 60 ℃, the time of grafting is 1h, and the liquor ratio of grafting is 1:40. The fibers after grafting are washed with deionized water, dried, and then dyed. The dyeing agent is 4% (o.w....

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com