Temperature measuring system and method for on-line measurement of molten steel temperature in steelmaking process of electric-arc furnace

A molten steel temperature and electric arc furnace technology, which is applied in the field of electric arc furnace steelmaking, can solve the problems of limited number of temperature measurements, inability to stably pass through the spectral signal, and high content of smoke and dust in the furnace gas, and achieve the effect of ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

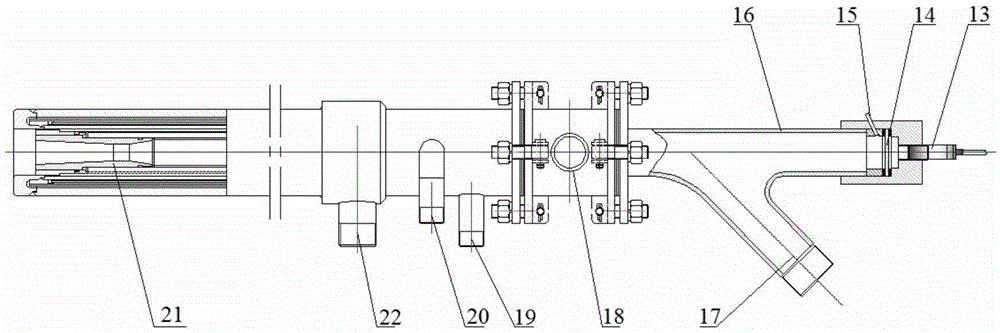

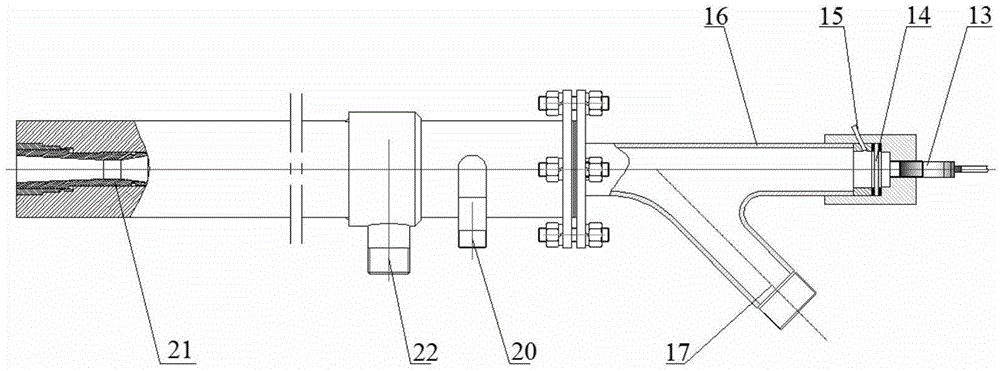

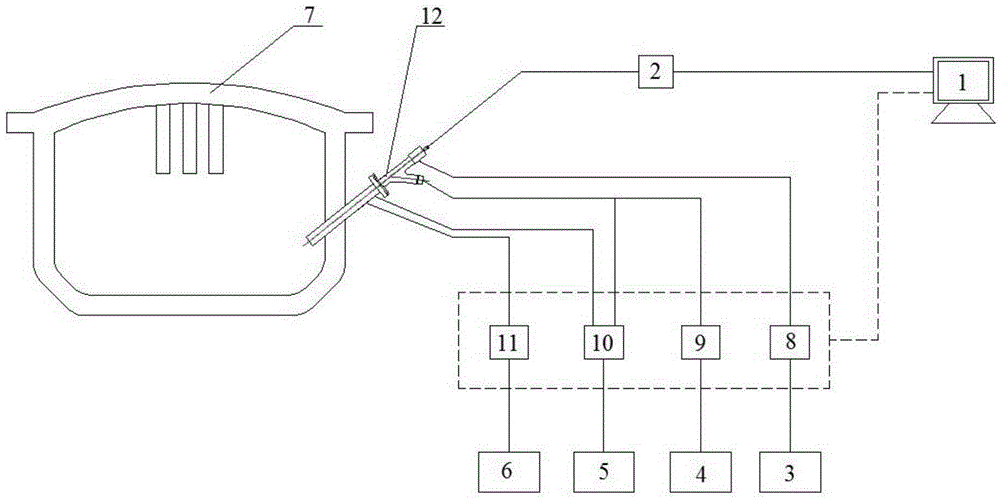

[0050] The present invention is applied in 100-ton electric arc furnace steelmaking. The position of the spray gun on the wall of the electric arc furnace is 60° from the horizontal plane. It is smelted with a ratio of 50% molten iron. The Mach number of the nozzle is 2 and the gas flow rate is 2500m. 3 / h, pressure 0.8MPa, a total of 4 furnace wall spray guns (No. 1~4) (such as image 3 shown), wherein No. 4 furnace wall spray gun is installed according to the transformation of the present invention, and the temperature measuring gas adopts N 2 , The transparent protective glass is made of pressure-resistant transparent quartz glass, the purge gas is air, the furnace wall spray gun of the electric arc furnace adopts a cluster jet spray gun, and the infrared temperature measuring device adopts an infrared thermometer. The molten steel temperature measurement in the smelting process adopts the online discontinuous measurement mode of molten steel temperature, which specifically...

example 2

[0060] The present invention is applied in 150-ton electric arc furnace steelmaking. The position of the spray gun on the electric arc furnace wall and the horizontal plane are installed at 60°. It is smelted with 100% solid metal material. The Mach number of the nozzle is 2 and the gas flow rate is 3000m 3 / h, pressure 0.8MPa, a total of 4 furnace wall spray guns (No. 1~4), wherein No. 4 furnace wall spray guns are rebuilt and installed according to the present invention, and the temperature measuring gas adopts N 2 , The transparent protective glass is pressure-resistant transparent quartz glass, the purge gas is air, the electric arc furnace wall spray gun is a supersonic gun, and the infrared temperature measurement device is an infrared thermal imager. The molten steel temperature measurement in the smelting process adopts the online continuous measurement mode of molten steel temperature, which specifically includes the following contents:

[0061] During the smelting pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com