Anti-ultraviolet material, anti-ultraviolet film and preparation method of film

An anti-ultraviolet and ultraviolet technology, which is applied in epoxy resin coatings, reflective/signal coatings, radiation-absorbing coatings, etc., can solve the problems of easy aging and poor anti-ultraviolet effect, and achieve cost control, high ultraviolet reflectance and absorption rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

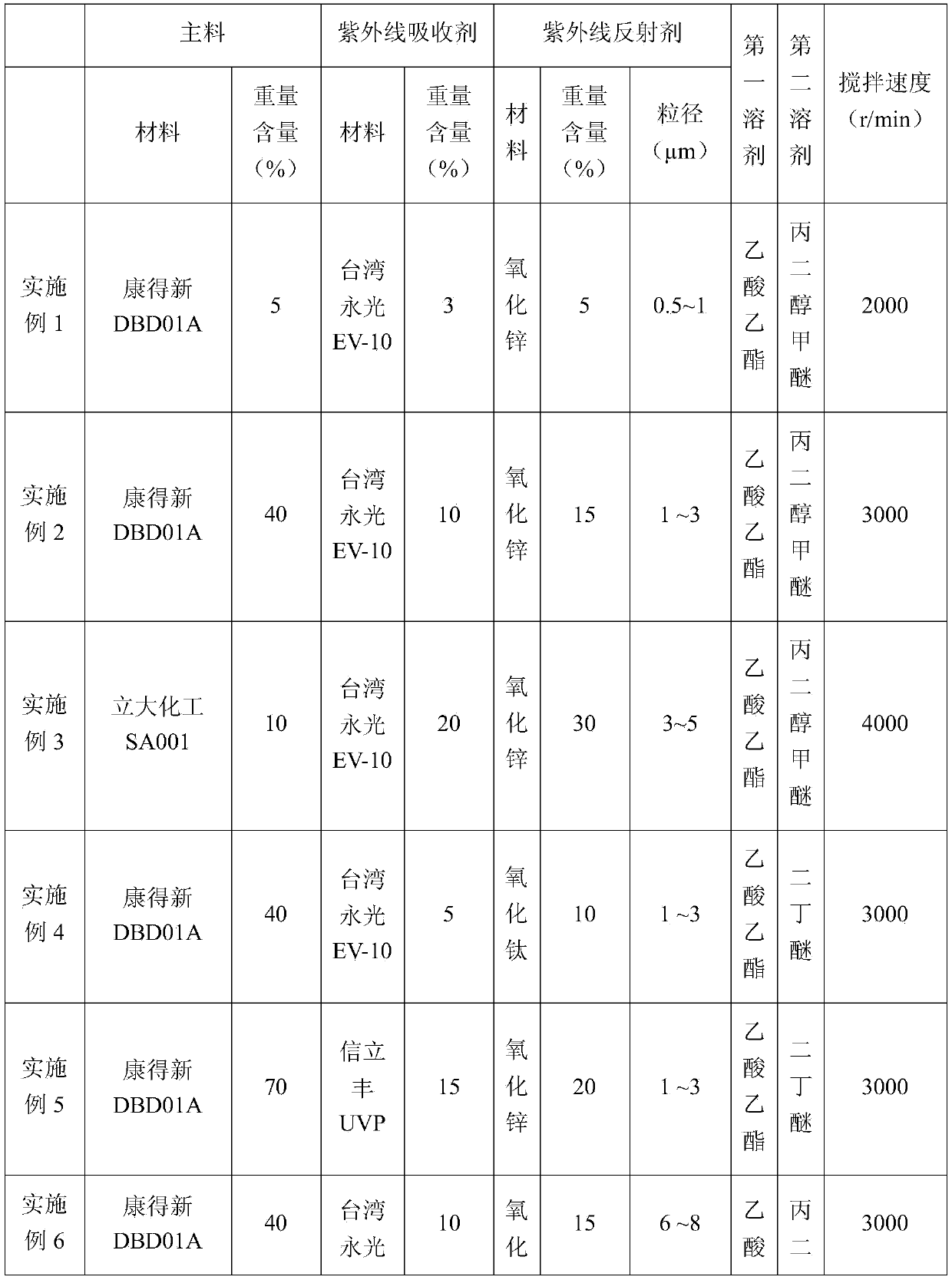

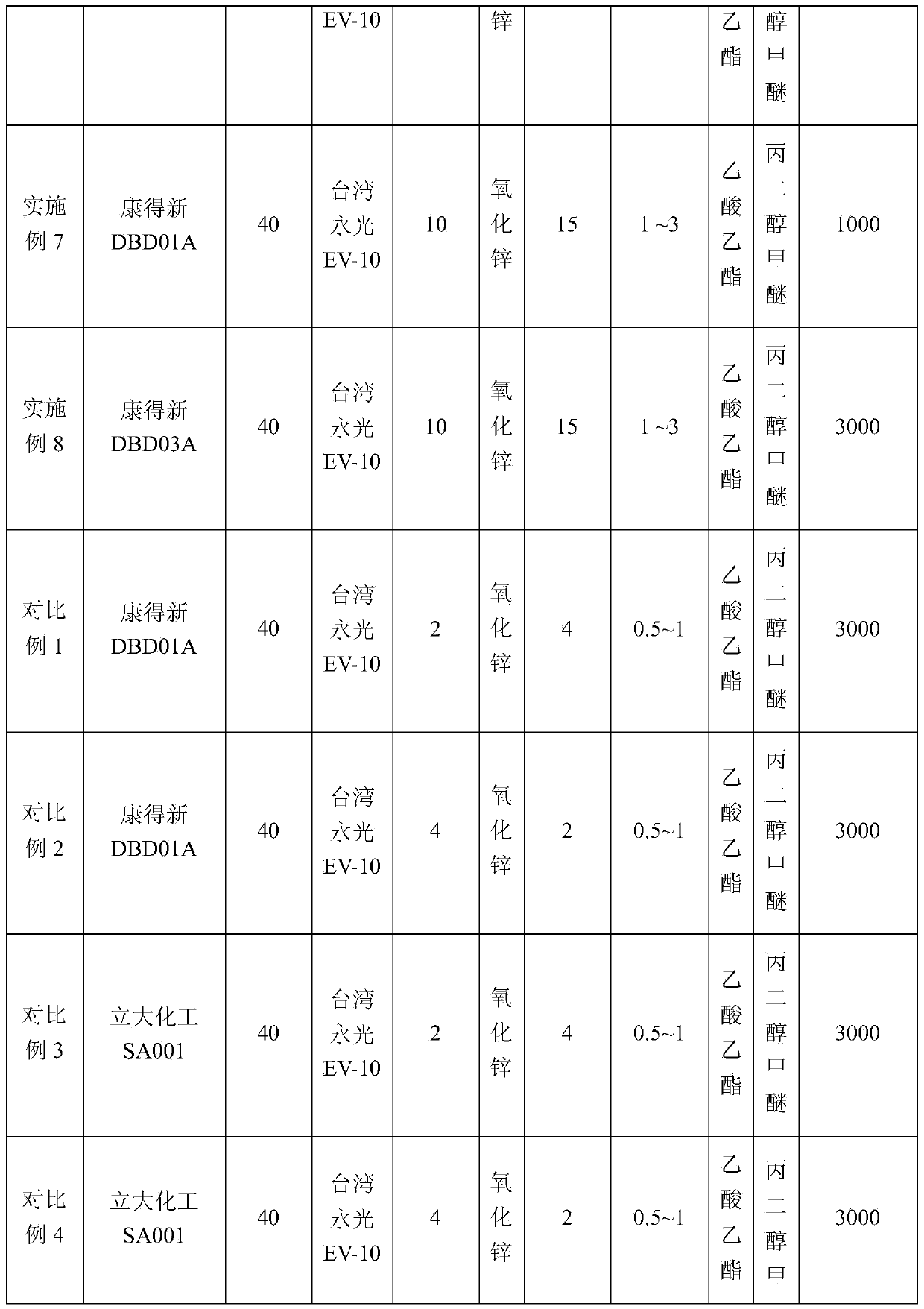

[0055] Dilute the thermosetting resin (main ingredient) DBD01A of Kangdexin Company with the first solvent ethyl acetate to form the first mixture, and zinc oxide with a particle size between 0.5 and 1 μm of Dongxin Chemical Company The powder is mixed with a second solvent, propylene glycol methyl ether, to form a second mixture.

[0056] The ultraviolet absorber model EV-10 of Taiwan Yongguang Company was added to the second mixture to form the third mixture.

[0057] Add the first mixture to the third mixture, and stir it into a homogenous slurry to form an anti-ultraviolet material during the addition process. The stirring speed is 2000r / min. The raw materials and contents of each component in the formed material are shown in Table 1.

[0058] The material was coated on a transparent PET substrate with a thickness of 125 μm, placed in a blast oven for 2 minutes, and the temperature in the oven was 80° C., and dried to obtain an ultraviolet-resistant film. The specific par...

Embodiment 2

[0060] Dilute the thermosetting resin (main ingredient) DBD01A of Kangdexin Company with ethyl acetate to form the first mixture, and the zinc oxide powder with a particle size between 1 and 3 μm of Dongxin Chemical Company and the second The solvent propylene glycol methyl ether is mixed to form a second mixture.

[0061] The ultraviolet absorber model EV-10 of Taiwan Yongguang Company was added to the second mixture to form the third mixture.

[0062] Add the first mixture to the third mixture, and stir to form a homogenous slurry to form an anti-ultraviolet material during the addition process. The stirring speed is 3000r / min. The raw materials and contents of each component in the formed material are shown in Table 1.

[0063] The material was coated on a transparent PET substrate with a thickness of 125 μm, placed in a blast oven for 2 minutes, and the temperature in the oven was 80° C., and dried to obtain an ultraviolet-resistant film. The specific parameters are shown...

Embodiment 3

[0065] Dilute the light-curable resin (namely the main material) of Lida Chemical Industry SA001 with the first solvent ethyl acetate to form the first mixture, and the zinc oxide powder with a particle size of 3-5 μm from Dongxin Chemical Company and The second solvent, propylene glycol methyl ether, is mixed to form a second mixture.

[0066] The ultraviolet absorber model EV-10 of Taiwan Yongguang Company was added to the second mixture to form the third mixture.

[0067] Add the first mixture to the third mixture, and stir it into a homogenous slurry to form an anti-ultraviolet material during the addition process. The stirring speed is 4000r / min. The raw materials and contents of each component in the formed material are shown in Table 1.

[0068] The material is coated on a transparent PET substrate with a thickness of 125 μm, placed in a blast oven for 1 min, the temperature in the oven is 80 ° C, and placed at 800 mJ / cm 2 In the UV conveyor, it is dried to obtain a UV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com