Method for preparing terlipressin

A technology for terlipressin and intermediates, which is applied in the field of preparation of terlipressin, can solve the problems of peptide chain breakage, long oxidation process time and high cost, and achieves reduction of missing peptide impurities, product quality advantages, and total cost. The effect of cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 : Synthesis of Fmoc-Gly-RinkAmide Resin

[0033] Add 20 grams of RinkAmide resin (1.00mmol / g) to the reaction column, add DMF to swell for 30 minutes; 5min and 8min, and then washed six times with DMF. Fmoc-Gly-OH (17.8g, 60mmol), HOBt (8.2g, 60mmol) and DIC (7.6g, 60mmol) were dissolved in an appropriate amount of DMF and added to the above reaction column, and reacted at room temperature for 120min. After the reaction was completed, the reaction solution was vacuumed off, and washed six times with DMF to obtain the Fmoc-Gly-RinkAmide resin.

Embodiment 2

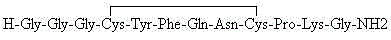

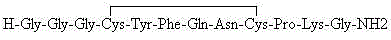

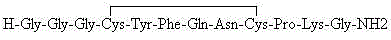

[0035] Synthesis of Fmoc-Gly-Cys(Trt)-Tyr(tBu)-Phe-Gln(Trt)-Asn(Trt)-Cys(Trt)-Pro-Lys(Boc)-Gly-RinkAmide Resin

[0036] Take the Fmoc-Gly-RinkAmide resin prepared in the above Example 1, add the DBU / hexahydropyridine / DMF solution with a ratio of 2 / 10 / 88 to deprotect twice, 5min and 8min respectively, and then wash with DMF for six Second-rate. Fmoc-Lys(Boc)-OH (28.1g, 60mmol), HOBt (8.2g, 60mmol) and DIC (7.6g, 60mmol) were dissolved with appropriate amount of DMF and added to the above reaction column, and reacted at room temperature for 120min. After the reaction was completed, the reaction solution was vacuumed off and washed six times with DMF to obtain Fmoc-Lys(Boc)-Gly-RinkAmide resin.

[0037] In the same way, Fmoc-Pro-OH, Fmoc-Cys(Trt)-OH, Fmoc-Asn(Trt)-OH, Fmoc-Gln(Trt)-OH, Fmoc-Phe-OH, Fmoc-Tyr(tBu)- OH, Fmoc-Cys(Trt)-OH, Fmoc-Gly-OH were connected to Fmoc-Lys(Boc)-Gly-RinkAmide resin to obtain Fmoc-Gly-Cys(Trt)-Tyr(tBu)-Phe-Gln( Trt)-Asn(Trt)-Cys(Trt)-Pro-Lys(Boc...

Embodiment 3

[0039] Synthesis of Boc-Gly-Gly-Gly-Cys(Trt)-Tyr(tBu)-Phe-Gln(Trt)-Asn(Trt)-Cys(Trt)-Pro-Lys(Boc)-Gly-resin

[0040] Get the intermediate prepared in the above-mentioned embodiment 2

[0041] Fmoc-Gly-Cys(Trt)-Tyr(tBu)-Phe-Gln(Trt)-Asn(Trt)-Cys(Trt)-Pro-Lys(Boc)-Gly-RinkAmide resin, the addition ratio is 2 / 10 / 88 DBU / hexahydropyridine / DMF solution for deprotection twice, 5min and 8min respectively, and then washed six times with DMF. Boc-Gly-Gly-OH (14.0g, 60mmol), HOBt (8.2g, 60mmol) and DIC (7.6g, 60mmol) were dissolved in an appropriate amount of DMF and added to the above reaction column, and reacted at room temperature for 120min. After the reaction was completed, the reaction solution was removed in vacuo, washed six times with DMF, shrunk three times with methanol, and dried in vacuo to constant weight to obtain Boc-Gly-Gly-Gly-Cys(Trt)-Tyr(tBu)-Phe-Gln( Trt)-Asn(Trt)-Cys(Trt)-Pro-Lys(Boc)-Gly-resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com