Preparation method of 3-hydroxy piperidine

A technology of hydroxypiperidine and hydroxypyridine, which is applied in the field of synthesis of 3-hydroxypiperidine, can solve the problems of long synthesis steps, poor atom economy, harsh reaction conditions, etc., achieve stable yield, weaken passivation, and recycle high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

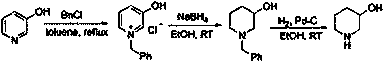

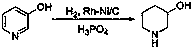

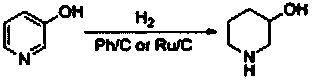

Method used

Image

Examples

Embodiment 1

[0025] Weigh 1 g of rhodium-nickel / carbon bimetallic catalyst (10% rhodium and 1% nickel), 10 g (0.11 mol) of 3-hydroxypyridine, 0.3 g (3.1 mmol) of phosphoric acid, and isopropanol (55 mL) As a solvent, put it into the reactor and pass hydrogen to the internal pressure of 3atm, 25 o C reacted for 3h, released hydrogen after the reaction was over, filtered the catalyst, concentrated the reaction solution under reduced pressure, and obtained crude product was distilled under reduced pressure (65-67 oC ,2mmHg) to get 10.7g of 3-hydroxypiperidine, yield: 96%; 1 HNMR (400MHz, CDCl 3 ):δ=3.56(m,1H),2.99(m,1H),2.80-2.39(m,3H),1.93(m,1H),1.74(m,1H),1.51-1.33(m,3H)ppm .

Embodiment 2

[0027] Weigh 500g of rhodium-nickel / carbon bimetallic catalyst (the rhodium content is 5%, the nickel content is 0.5%), 3-hydroxypyridine 10kg (105.3mol), phosphoric acid 0.5kg (5.1mol), water (42L) as solvent , put into the reactor and pass hydrogen to the internal pressure of 5atm, 50 o C reacted for 30min, released hydrogen after the reaction was over, filtered the catalyst, and the reaction liquid was distilled under reduced pressure (65-67 o C, 2mmHg) to obtain 9.78kg of 3-hydroxypiperidine, yield: 92%.

Embodiment 3

[0028] Embodiment 3 Catalyst recovery experiment

[0029] Weigh 100g of rhodium-nickel / carbon bimetallic catalyst (wherein rhodium content is 10%, nickel content is 1%), 3-hydroxypyridine 1kg (10.53mol), phosphoric acid 30g (0.31mol), water (5L) as solvent, Put hydrogen into the reactor to the internal pressure of 3atm, 50 o C reaction, release hydrogen after the reaction is over, filter out the catalyst and directly use it for the next catalytic cycle, and the reaction liquid is distilled under reduced pressure (65-67 oC , 2mmHg) to 3-hydroxypiperidine. Catalyst recycling 8 times product yield is as follows:

[0030] Cycles Reaction time (h) Product yield (%) 1 1 95 2 1 94.5 3 1 93.8 4 1.5 94.5 5 1.5 93.2 6 2 94 7 2 94.5 8 2 94

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com