Compound microbial fertilizer with disease and pest resistance as well as preparation method and application of compound microbial fertilizer

A technology of compound microorganisms and compound microbial agents, applied in the field of compound microbial fertilizers resistant to pests and diseases and its preparation, can solve the problems of insignificant effect, low microbial content, and small number of beneficial bacteria, so as to improve the ability of resisting pests and diseases, and promote Effect of plant growth and improvement of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

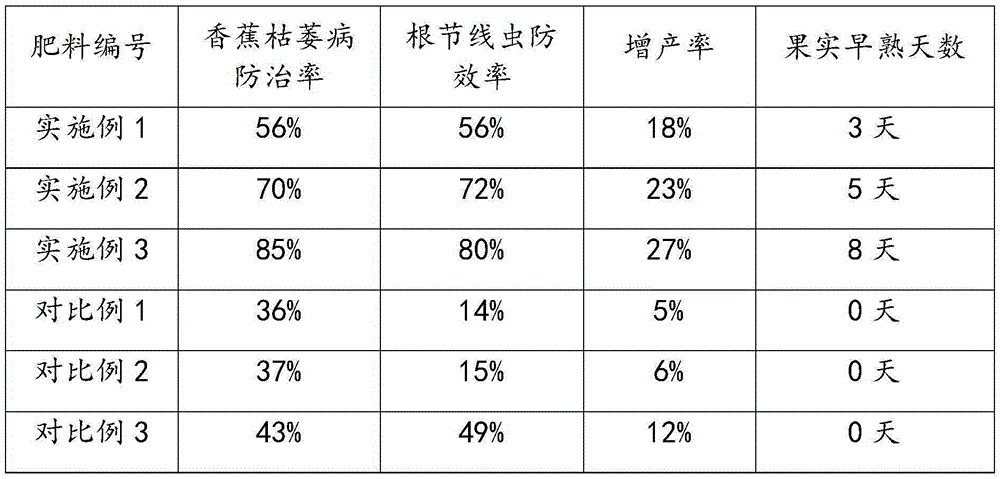

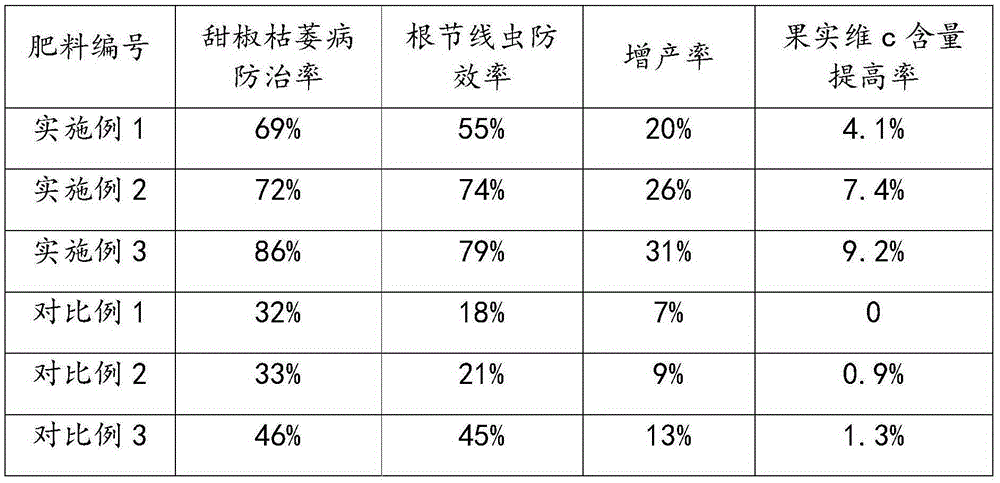

Examples

Embodiment 1

[0041] 1) Select 50 parts of yeast powder, 12 parts of auxiliary materials, 10 parts of waste molasses, 5 parts of compound microbial bacterial agent, and 1 part of Paecilomyces lilacinus.

[0042] The yeast powder is concentrated and dried powder of at least one of amino acid waste liquid, monosodium glutamate factory waste liquid, yeast factory waste liquid and sugar factory waste liquid, and its composition is 13% of nitrogen, phosphorus and potassium. 2% trace elements, 4.8% amino acids, 0.2% water-insoluble matter, 75% organic matter, 5% moisture, and a pH of about 7.

[0043] The auxiliary material is at least one of the following decomposed clinker materials: plant residues, kitchen waste, human and animal manure or sludge.

[0044] The composite microbial agent is composed of 25% by weight of Bacillus subtilis, 25% of Bacillus amyloliquefaciens, 15% of Bacillus megaterium and 35% of Bacillus licheniformis.

[0045] 2) Mix and sieve the above-mentioned yeast powder and...

Embodiment 2

[0050] 1) Select 60 parts of yeast powder, 16 parts of auxiliary materials, 14 parts of waste molasses, 8 parts of compound microbial bacterial agent, and 2 parts of Paecilomyces lilacinus.

[0051] The yeast powder is concentrated and dried powder of at least one of amino acid waste liquid, monosodium glutamate factory waste liquid, yeast factory waste liquid, and sugar factory waste liquid. 2.6% trace elements, 6% amino acids, 0.4% water-insoluble matter, 71% organic matter, 5% moisture, pH about 6.8.

[0052] The auxiliary material is at least one of the following decomposed clinker materials: plant residues, kitchen waste, human and animal manure or sludge.

[0053] The composite microbial bacterial agent is composed of 30% by weight of Bacillus subtilis, 20% of Bacillus amyloliquefaciens, 20% of Bacillus megaterium and 30% of Bacillus licheniformis.

[0054] 2) Mix and sieve the above-mentioned yeast powder and auxiliary materials according to weight parts, sterilize, an...

Embodiment 3

[0059] 1) Select 78 parts of yeast powder, 20 parts of auxiliary materials, 18 parts of waste molasses, 10 parts of compound microbial bacterial agent, and 3 parts of Paecilomyces lilacinus.

[0060] The yeast powder is concentrated and dried powder of at least one of amino acid waste liquid, monosodium glutamate factory waste liquid, yeast factory waste liquid, and sugar factory waste liquid. 3% trace elements, 3.7% amino acids, 0.3% water-insoluble matter, 68% organic matter, 5% moisture, and a pH of about 7.2.

[0061] The auxiliary material is at least one of the following decomposed clinker materials: plant residues, kitchen waste, human and animal manure or sludge.

[0062] The composite microbial agent is composed of 30% by weight of Bacillus subtilis, 25% of Bacillus amyloliquefaciens, 20% of Bacillus megaterium and 25% of Bacillus licheniformis.

[0063] 2) Mix and sieve the above-mentioned yeast powder and auxiliary materials according to weight parts, sterilize, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com