Treatment device and treatment method for simultaneously removing high-concentration SS, fluoride, sulfate, arsenate and cod in desulfurization wastewater

A technology for desulfurization wastewater and treatment methods, which is applied in chemical instruments and methods, gaseous discharge wastewater treatment, water/sewage multi-stage treatment, etc. Stable operation, unique effects conceived

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

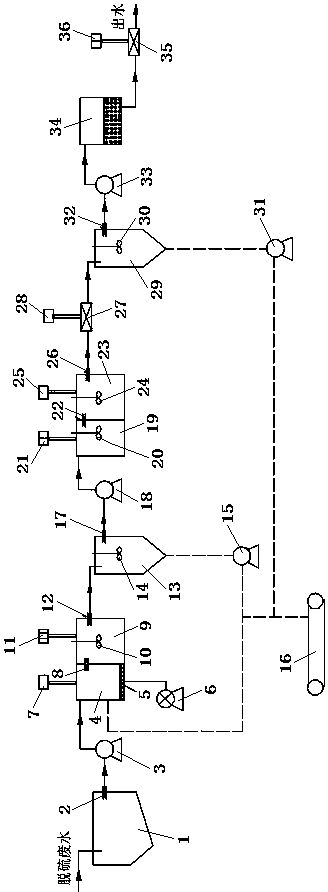

[0028] see figure 1 In this embodiment, the treatment device for simultaneously removing high-concentration SS, fluoride, sulfate, arsenate and COD in desulfurization wastewater includes a sedimentation tank 1 provided with a sedimentation tank overflow port 2, a No. 1 delivery pump 3, and a The first reaction tank 4 of the first reaction tank overflow port 8, the aeration device 5 and the blower 6 arranged at the bottom of the first reaction tank 4 are used to add CaO or Ca(OH) 2 The No. 1 dosing device 7, the second reaction tank 9 with the second reaction tank overflow port 12, the second reaction tank stirring device 10, the No. 2 dosing device for adding calcium salt, acid and flocculant 11. The primary clarifier 13 with the primary clarifier overflow port 17, the primary clarifier stirring device 14, the No. 1 sludge delivery pump 15, the sludge disposal mechanism 16, the No. 2 delivery pump 18, and the third The third reaction box 19 of the overflow port 22 of the rea...

Embodiment 2

[0045] see figure 1 In this embodiment, the treatment device for simultaneously removing high-concentration SS, fluoride, sulfate, arsenate and COD in desulfurization wastewater includes a sedimentation tank 1 provided with a sedimentation tank overflow port 2, a No. 1 delivery pump 3, and a The first reaction tank 4 of the first reaction tank overflow port 8, the aeration device 5 and the blower 6 arranged at the bottom of the first reaction tank 4 are used to add CaO or Ca(OH) 2 The No. 1 dosing device 7, the second reaction tank 9 with the second reaction tank overflow port 12, the second reaction tank stirring device 10, the No. 2 dosing device for adding calcium salt, acid and flocculant 11. The primary clarifier 13 with the primary clarifier overflow port 17, the primary clarifier stirring device 14, the No. 1 sludge delivery pump 15, the sludge disposal mechanism 16, the No. 2 delivery pump 18, and the third The third reaction box 19 of the overflow port 22 of the rea...

Embodiment 3

[0060] see figure 1 In this embodiment, the treatment device for simultaneously removing high-concentration SS, fluoride, sulfate, arsenate and COD in desulfurization wastewater includes a sedimentation tank 1 provided with a sedimentation tank overflow port 2, a No. 1 delivery pump 3, and a The first reaction tank 4 of the first reaction tank overflow port 8, the aeration device 5 and the blower 6 arranged at the bottom of the first reaction tank 4 are used to add CaO or Ca(OH) 2 The No. 1 dosing device 7, the second reaction tank 9 with the second reaction tank overflow port 12, the second reaction tank stirring device 10, the No. 2 dosing device for adding calcium salt, acid and flocculant 11. The primary clarifier 13 with the primary clarifier overflow port 17, the primary clarifier stirring device 14, the No. 1 sludge delivery pump 15, the sludge disposal mechanism 16, the No. 2 delivery pump 18, and the third The third reaction box 19 of the overflow port 22 of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com