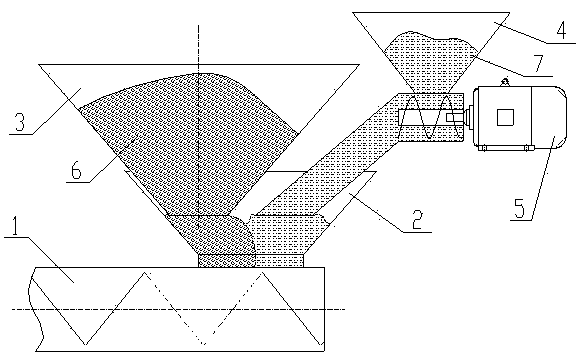

Feed device for production of flame-resistant XPS plastic extruding foam boards

A technology of feeding device and foam board, which is applied in the field of feeding device, can solve the problems of lack of flexibility, change of flame retardant performance, inconvenience, etc., and achieve the effect of simple and flexible production process, stable flame retardant performance and safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1 part of red phosphorus, 2 parts of expandable graphite, 4 parts of PS powder, 0.02 part of antioxidant, and 0.03 part of TCPP are used to form a flame retardant premix. When the flame retardant premix and PS pellets are 3:7. The flame retardant XPS extruded foam board produced has a red phosphorus content of 4.28% and a graphite content of 8.57%. After injecting 2% of the total mass of TCPP on the secondary screw, the flame retardancy of the flame retardant XPS extruded foam board Can reach level B1.

Embodiment 2

[0033] 1 part of red phosphorus, 2 parts of expandable graphite, 4 parts of PS powder, 0.02 part of antioxidant, and 0.03 part of TCPP are used to form a flame retardant premix. When the flame retardant premix and PS pellets are 3.5:6.5. The flame retardant XPS extruded foam board produced contains 5% red phosphorus and 10% graphite, and the flame retardancy of the flame retardant XPS extruded foam board after injecting 1% of the total mass of TCPP on the secondary screw Can reach level B1.

Embodiment 3

[0035] 1 part of red phosphorus, 2 parts of expandable graphite, 4 parts of PS powder, 0.02 part of antioxidant, and 0.03 part of TCPP are used to form a flame retardant premix. When the flame retardant premix and PS pellets are 4:6. The flame retardant XPS extruded foam board produced contains 5.71% red phosphorus and 11.43% graphite. There is no need to inject TCPP into the secondary screw, and the flame retardancy of the flame retardant XPS extruded foam board can reach B1 level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com