Clean-in-place system for distillation device, preparation for cleaning liquid, and cleaning method

A distillation device and in-situ cleaning technology, applied in the direction of distillation adjustment/control, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems affecting mass transfer and heat transfer efficiency, blocking distillation devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

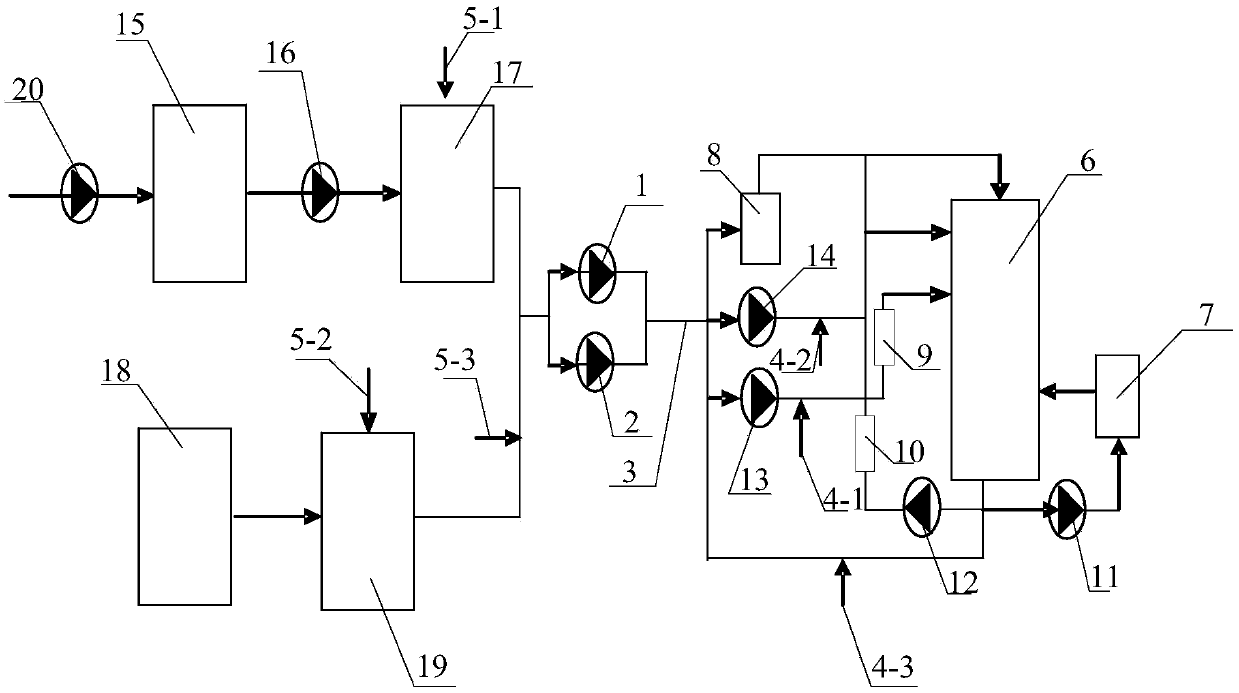

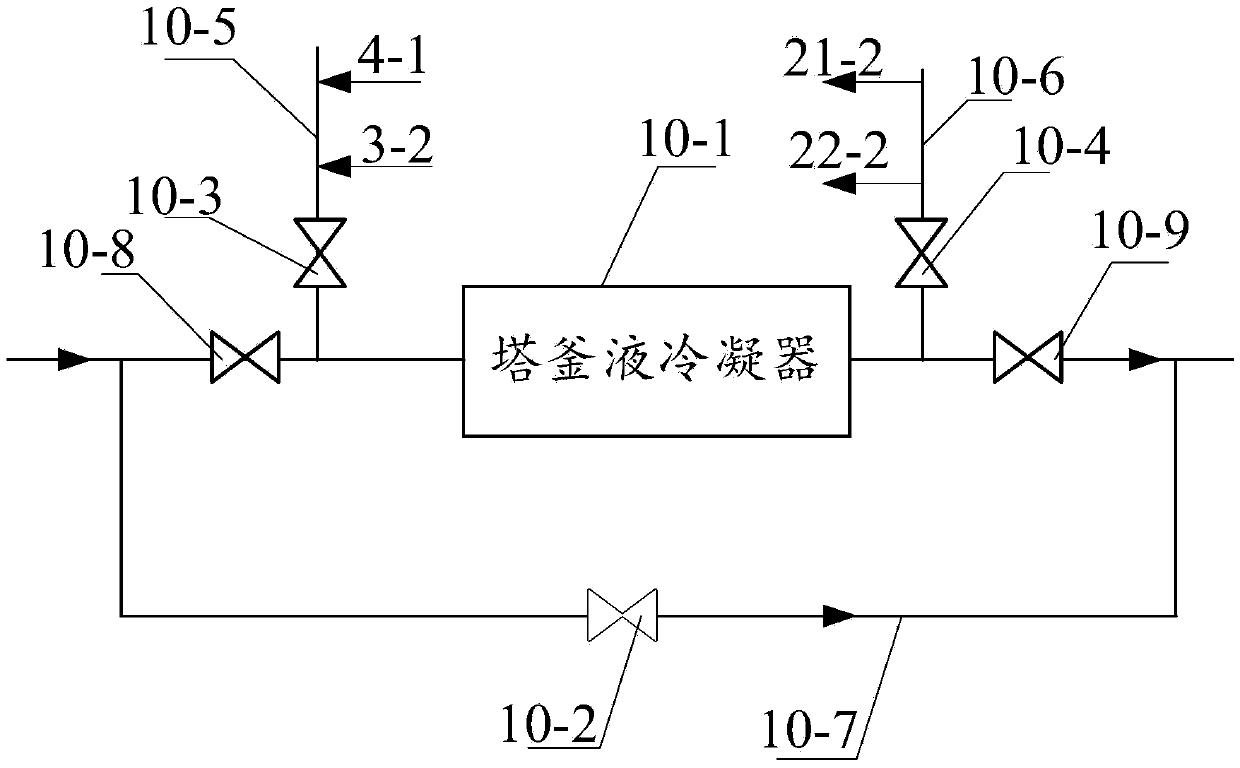

[0087] refer to figure 1 As shown, an in-situ cleaning system for a distillation device provided by an embodiment of the present invention is applied to the in-situ cleaning of a distillation device for producing ethanol by biological fermentation of gas. The in-situ cleaning system for a distillation device includes: a dilute alkali solution preparation device, lemon Acid mixing device, first CIP (CleanInPlace, in-situ cleaning) pump 1, second CIP pump 2, distillation device.

[0088] The liquid outlet of the dilute lye preparation device is respectively connected to the liquid inlet of the first CIP pump 1 and the liquid inlet of the second CIP pump 2, and the liquid outlet of the citric acid mixing device is respectively connected to the liquid inlet of the first CIP pump 1. The liquid inlet and the liquid inlet of the second CIP pump 2, the liquid outlet of the first CIP pump 1 and the liquid outlet of the second CIP pump 2 are all connected to the distillation device thro...

Embodiment 2

[0108] Based on the same inventive concept, the embodiment of the present invention provides a method for preparing lye for cleaning by applying the distillation device in-situ cleaning system described in the first embodiment above. figure 1 with Figure 4 Shown, the method for this preparation cleaning lye comprises the steps:

[0109] S101 : Start the concentrated lye delivery pump 16 to transport the raw lye in the concentrated lye storage tank 15 to the dilute lye storage tank 17 .

[0110] S102: control access to the process water inlet pipeline 5-1 in the dilute lye storage tank 17, add process water into the dilute lye storage tank 13 to dilute the original lye, and prepare dilute lye with a concentration ratio of 2%-3% .

[0111] Specifically, the process water on-off valve on the process water inlet pipeline 5-1 is controlled to be opened, and a certain amount of process water is injected into the dilute lye storage tank 17 through the process water inlet pipeline ...

Embodiment 3

[0118] Based on the same inventive concept, the embodiment of the present invention provides a method for preparing acid solution for cleaning by using the in-situ cleaning system of the distillation device in the above embodiment. figure 1 with Figure 5 Shown, the method for this preparation cleaning acid solution comprises the steps:

[0119] S201: The automatic weighing and conveying device 18 weighs the citric acid and delivers it to the citric acid mixing tank 19 according to the acid solution preparation amount and the acid solution ratio.

[0120] S202: Control the process water connected to the citric acid mixing tank 19 into the pipeline 5-2 to add the process water to the citric acid mixing tank 19 according to the acid solution preparation amount and acid solution ratio. For example, weigh citric acid according to the concentration ratio of 2%-3%. Specifically, control and open the process water on-off valve on the process water inlet pipeline 5-2, and inject a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com