Intensive ground electrode and installation method

An installation method and technology of grounding electrodes, which are applied in the direction of connection/disconnection of connection devices, connection contact materials, etc., can solve the problems of not meeting the design requirements, far from meeting the requirements, and limited floor space. The effect of construction period, improvement of construction quality, and cost savings of benches and shifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

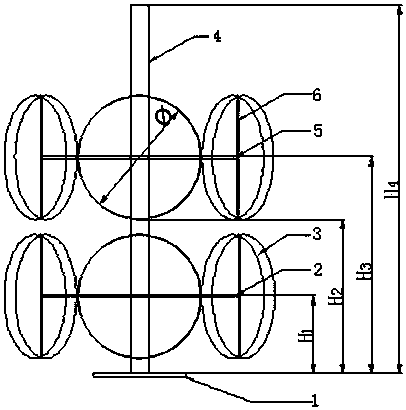

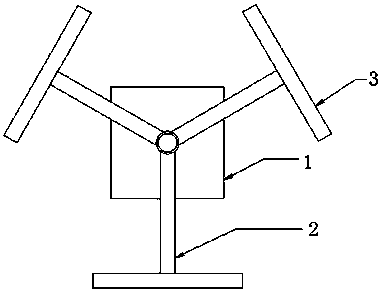

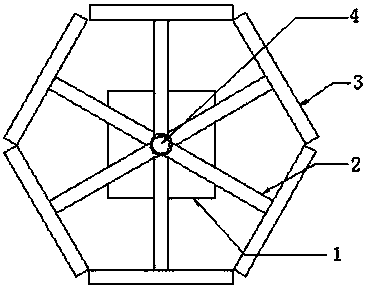

[0044] Example 2, such as Figure 5 versus Image 6 Shown: an intensive grounding electrode group, including three intensive grounding electrodes arranged in a positive triangle, the distance L between the centers of the two intensive grounding electrodes is 5 meters, and the grounding electrode bus 9 divides the centers of the three intensive grounding electrodes The upper outer surface of the electrode 4 is half-wrapped by 120° and welded to the center electrode.

[0045] The intensive grounding electrode is installed in the grounding electrode pit 8. Between the grounding electrode pits 8, a grounding busbar trench 7 is set. The grounding busbar 9 is located in the grounding busbar trench 7. The grounding busbar trench 7 and the grounding electrode pit 8 are made of clay, silt or Sand backfill. The ground electrode pit diameter D is about 1 meter; the ground bus groove depth H5 is 1 meter, and the ground electrode pit depth H6 is 2 meters; the ground electrode bus 9 is made o...

Embodiment 3

[0046] Example 3, see Figure 5 versus Image 6 , An intensive grounding electrode installation method, the specific method steps are as follows:

[0047] a. Excavate the ground electrode pit

[0048] Excavate three ground electrode pits 8 outside the shielded machine room. The depth of ground electrode pits H6 is 2m, and the diameter of ground electrode pits D is about 1m. Usually, the diameter of intensive grounding electrode plus 200mm is enough, which is convenient for filling and replacing soil. The electrode pits are arranged in a regular triangle, the center distance L between the two electrode pits, that is, the distance between the three ground electrode pits is 5m; the ground bus trench 7 is excavated between the three ground electrode pits, and one of the ground electrode pits is excavated and guided To the ground bus trench of the machine room, the excavation depth of the ground bus trench H5 is 1m and the width is 0.6m; the intensive grounding electrodes are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com