A kind of preparation method of lithium ion battery cathode material spherical nickel cobalt lithium aluminate

A nickel-cobalt lithium aluminate and lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of increased preparation difficulties, large amounts of ammonia nitrogen wastewater, poor spherical shape of precursor particles, etc., and achieve good cycle performance , high discharge specific capacity, good particle size distribution and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

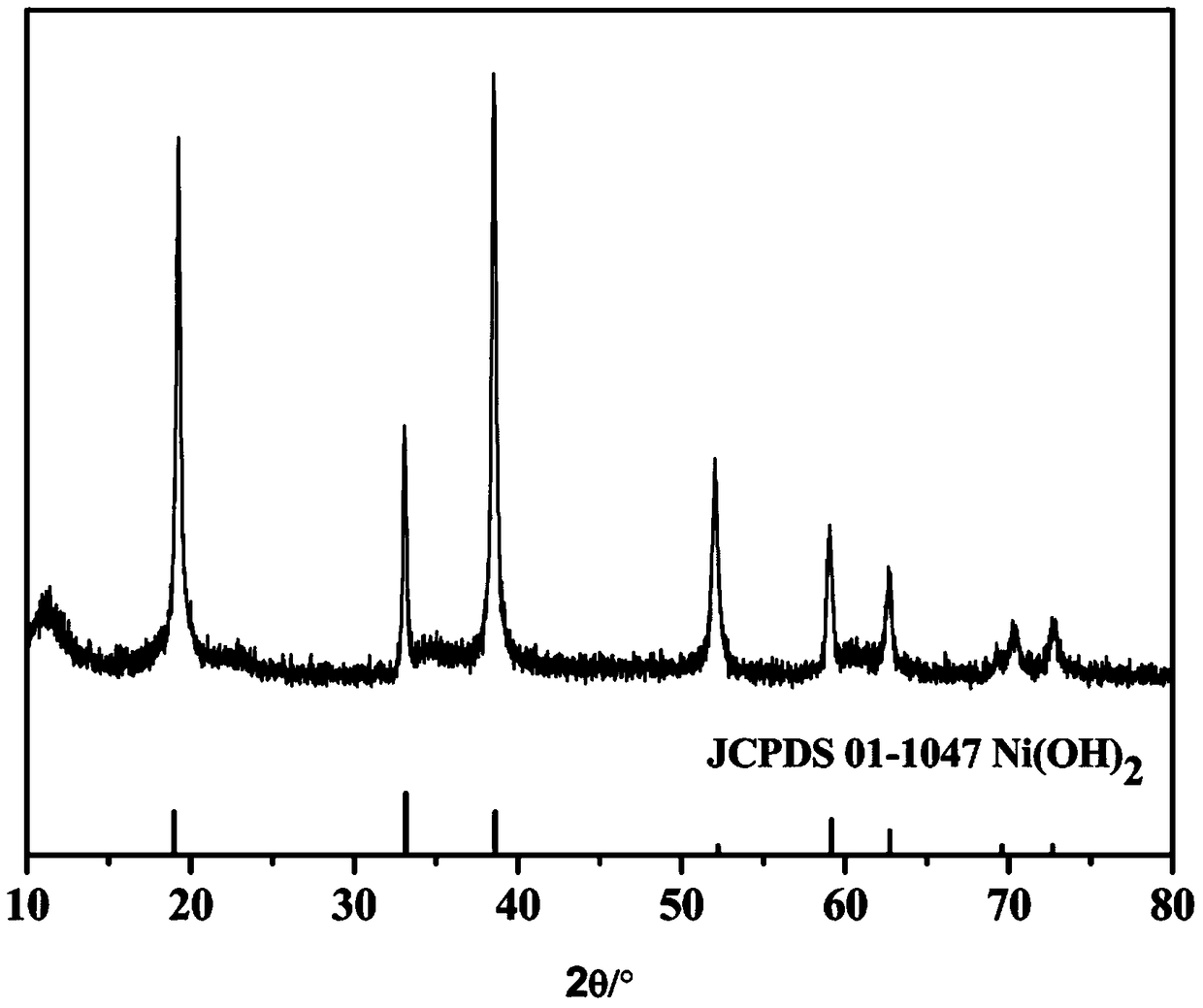

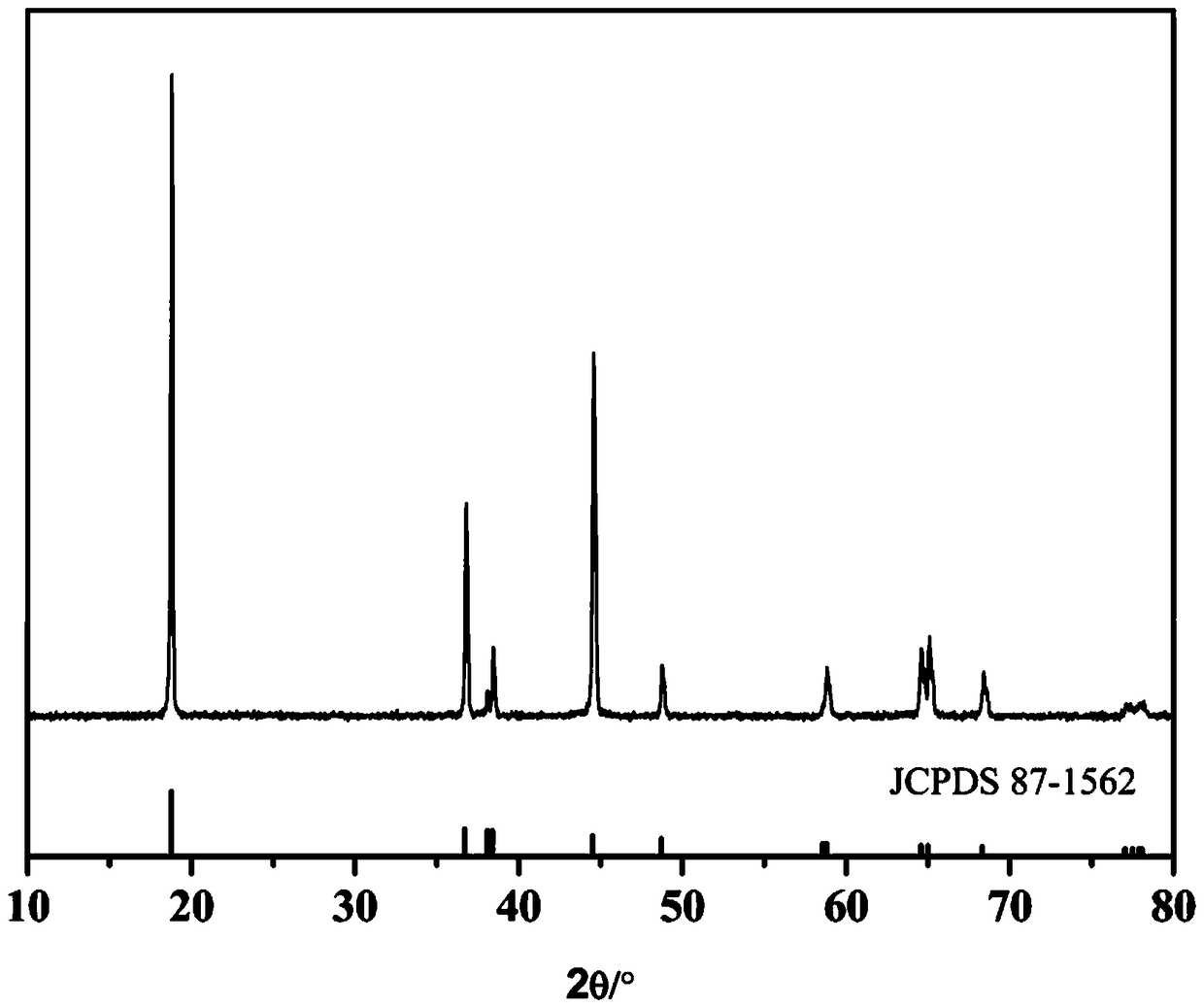

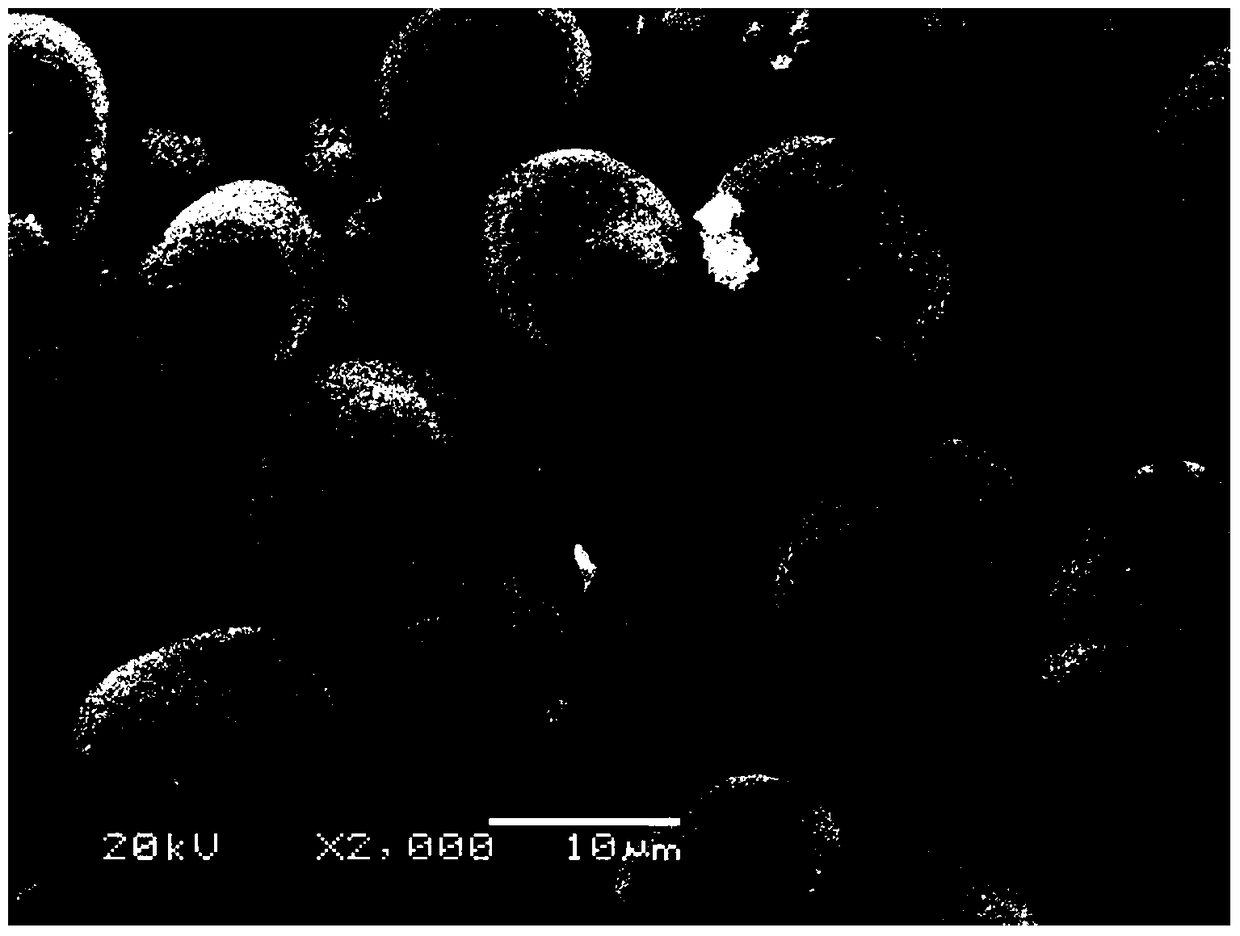

[0036] Add 821g of nickel sulfate and 171g of cobalt sulfate into 2000ml of deionized water and mix thoroughly, stir for 2h to fully dissolve and then let stand for 5h to obtain solution A; dissolve 67g of aluminum sulfate and 16g of NaOH in distilled water to obtain aqueous solution B, and seal it; Dissolve 320g NaOH in 2000ml deionized water to obtain solution C; dissolve 10gEDTA in 5000ml deionized water to obtain solution D, and put it in the reaction kettle; add the prepared three aqueous solutions of A, B, and C with D as the bottom solution In the high-speed stirring reactor (12L), control the feed rate of solution A, B to be 5ml / min, adjust the feed rate of solution C to control the pH value of the reaction system between 10-10.5, carry out with the speed of 400rpm Stir, heat to 40°C, finish the reaction after 6h, and then filter out the precursor of spherical nickel-cobalt-aluminum hydroxide; wash and filter the spherical nickel-cobalt-aluminum hydroxide obtained by fi...

Embodiment 2

[0038] Change the amount of EDTA added to 5g to prepare solution D, prepare solutions A, B and C according to the method of example 1, and prepare the precursor according to example 1 and then sinter to obtain the nickel cobalt lithium aluminate material. After testing, the average particle size of the lithium nickel cobalt aluminate is 11.4μm, and the tap density is 1.99g / cm 3 , the first charge-discharge efficiency is 87.1%, and the capacity retention rate after 100 cycles of 1C cycle is 90.7%.

Embodiment 3

[0040] Prepare the precursor according to the method of Example 1, control the pH value of the reaction to 11-11.5, and sinter according to the method of Example 1 to obtain the nickel cobalt lithium aluminate material. After testing, the average particle size of the lithium nickel cobalt aluminate is 10.98μm, and the tap density is 2.04g / cm 3 , the first charge and discharge efficiency was 86.7%, and the capacity retention rate was 88.1% after 100 cycles of 1C cycle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com