Piezo-actuated wire bonding setup

A wire bonding, piezoelectric drive technology, applied in circuits, electrical components, electrical solid devices and other directions, can solve the problems of difficult to stabilize and control the bonding force, complex force calibration process, etc., to achieve measurement and real-time feedback, reduce Overall mass and motion inertia, the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

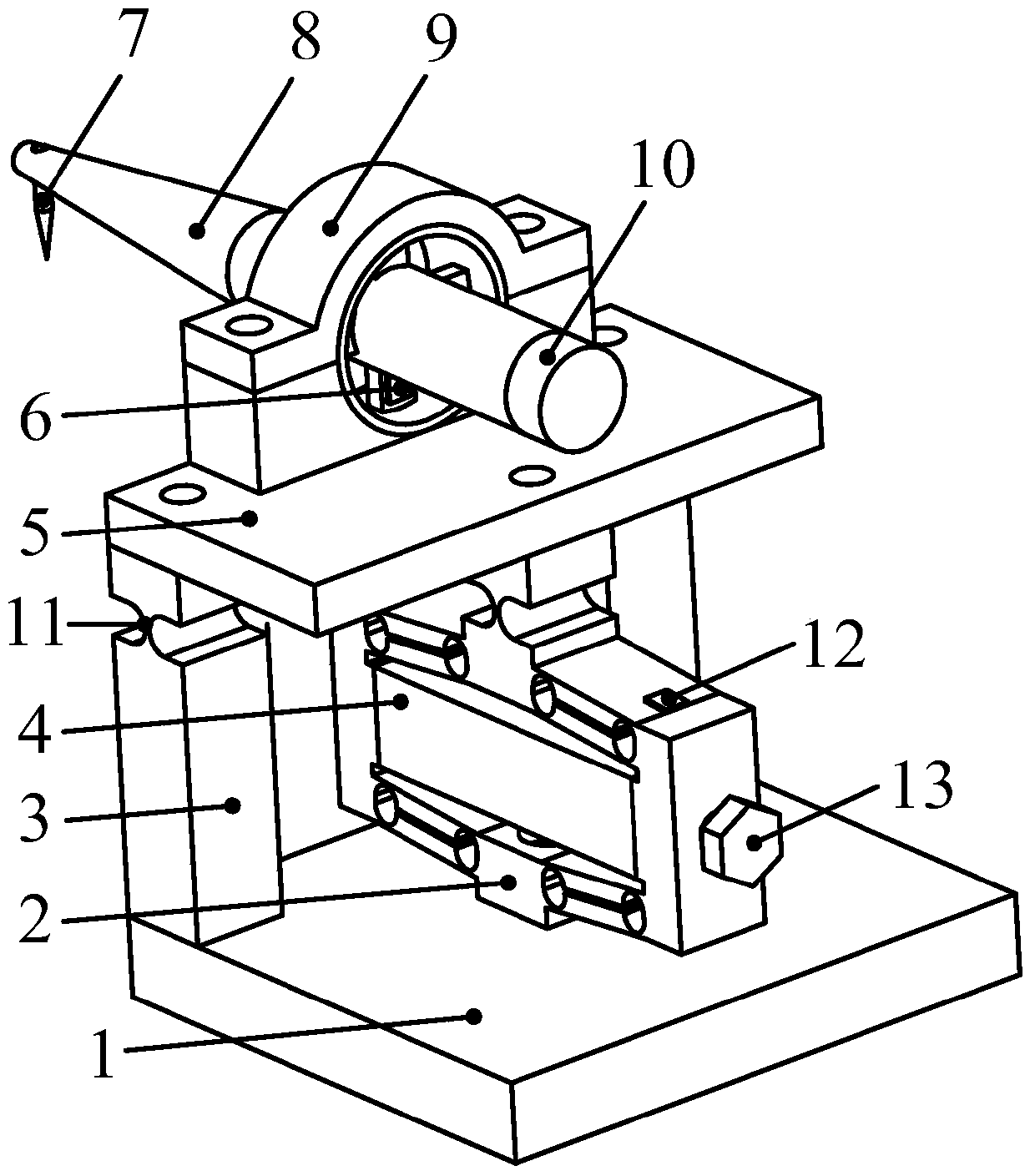

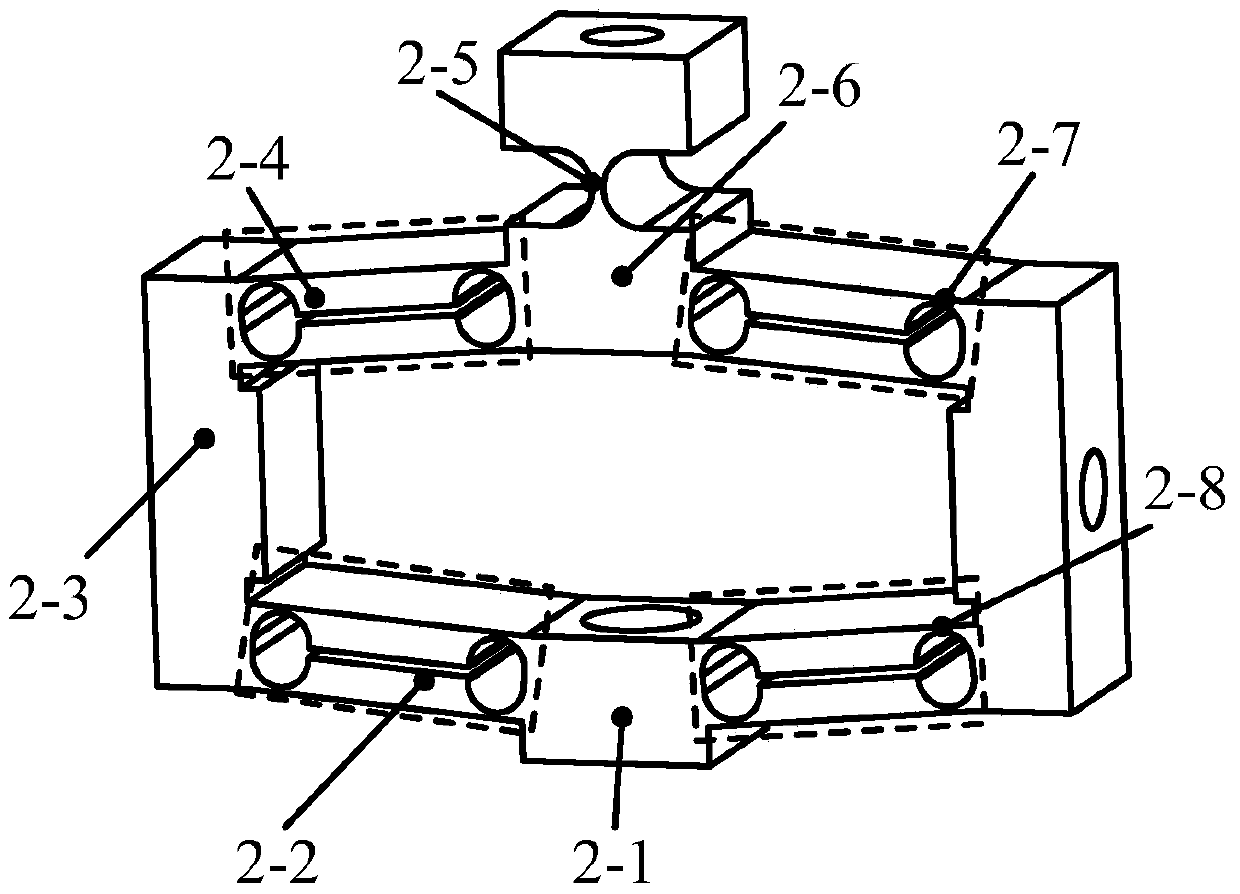

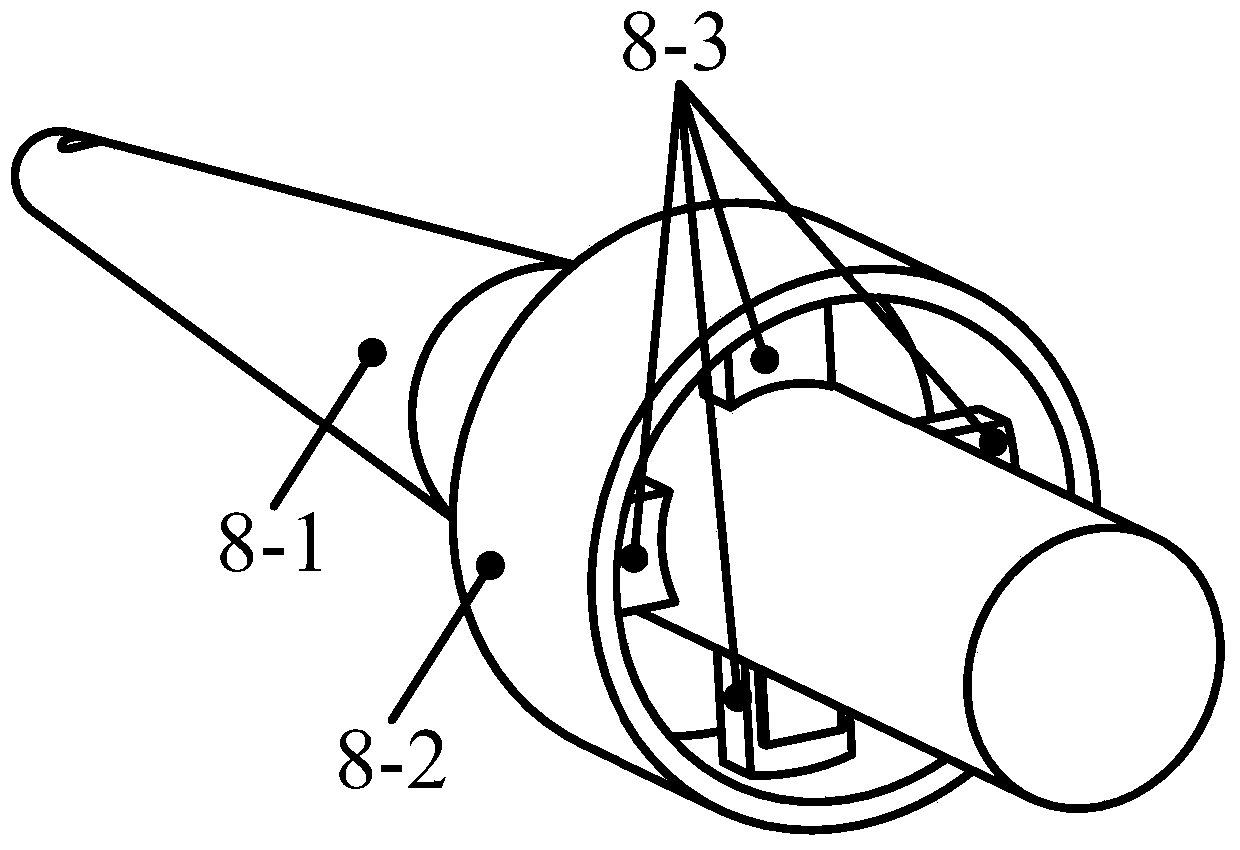

[0014] see Figure 1 ~ Figure 3 , a piezoelectric driven wire bonding device, including a base 1 and a swing platform 5 arranged above it; between the swing platform 5 and the base 1, two left and right columns 3 and a bridge-shaped An amplification mechanism 2, the bridge-type amplification mechanism 2 is centrally arranged between the two columns 3; the lower end of the column 3 is fixed on the front part of the upper surface of the base 1, and the upper end of the column 3 is flexibly Hinge IV11 is connected with the front part of the lower surface of the oscillating platform 5; the bridge type amplification mechanism 2 includes two movable connecting rods 2-3 arranged in parallel, and the movable connecting rod 2-3 is connected with the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com