Superconducting magnet comprising ferromagnetic rings

A technology of superconducting magnets and ferromagnetic rings, which is applied to superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problems of increasing ferromagnetic loss, excessive wire loss, and increasing the volume and weight of superconducting magnets. Achieve the effect of reducing the difficulty of winding and processing, avoiding the rapid quenching of the wire, and reducing the hidden danger of quenching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in combination with specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

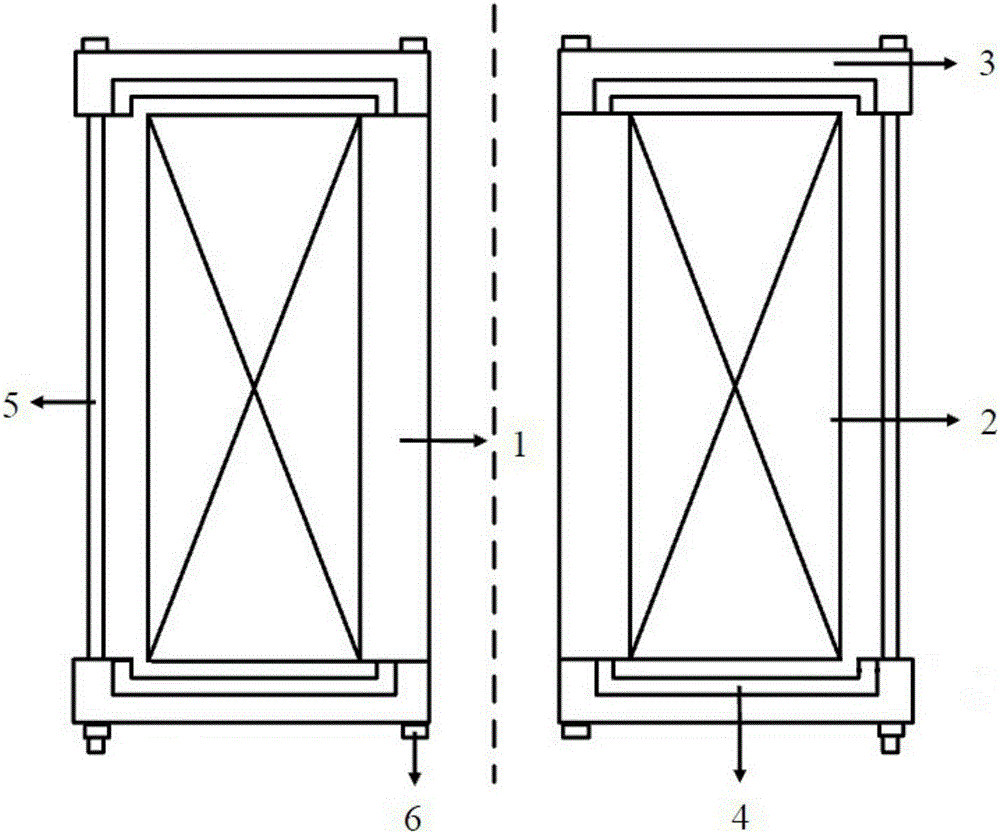

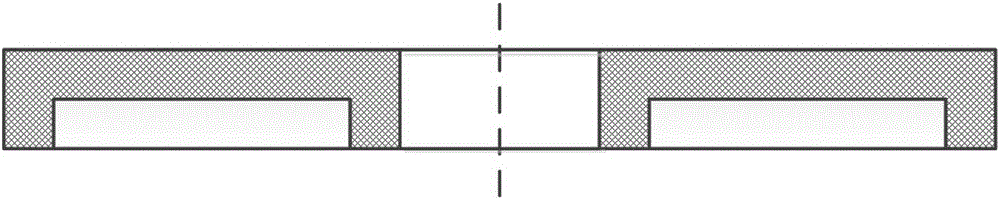

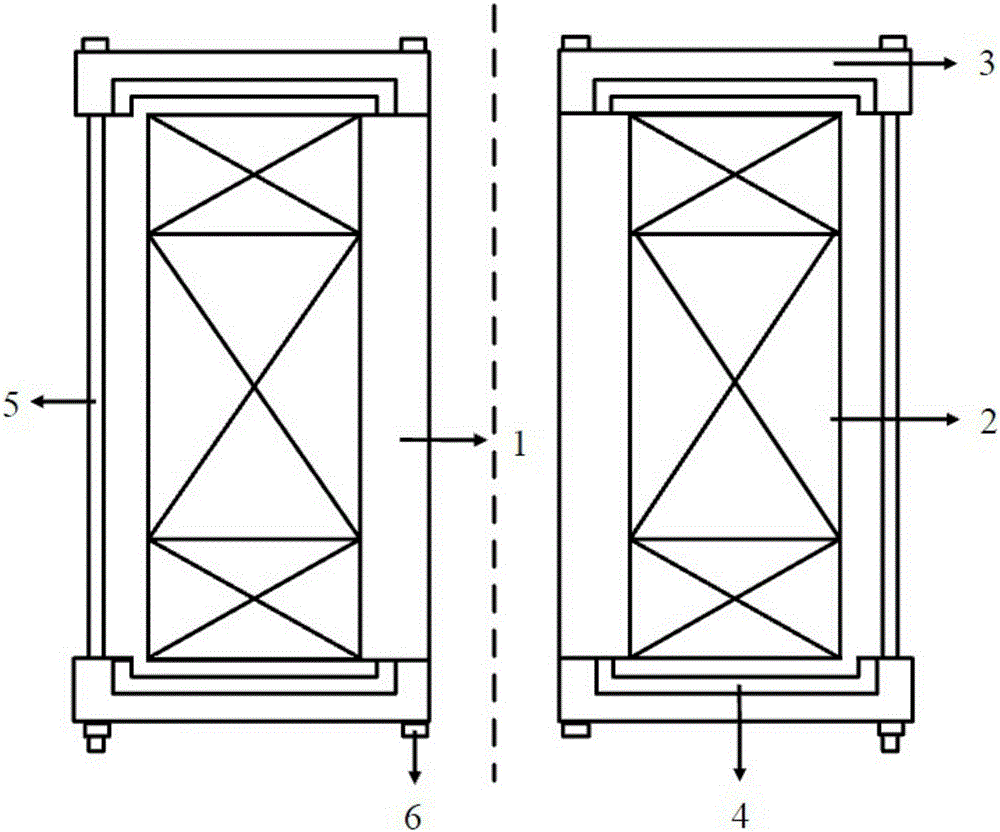

[0028] combine figure 1 with figure 2 Schematic diagram of the structure of the present invention and a sectional view of the ferromagnetic ring of the present invention shown respectively; wherein, the superconducting magnet containing the ferromagnetic ring of the present invention includes a non-magnetic cylindrical skeleton 1, a superconducting solenoid coil 2 and Two annular cover plates 3, and the superconducting solenoid coil 2 is wound on the non-magnetic cylindrical frame 1, and an annular cover plate 3 is provided at both ends of the non-magnetic cylindrical frame 1 to cover the supercondu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com