Line laser scanning-based sand blasting robot automatic path generation method

A path generation and robot technology, applied in the direction of instruments, details involving 3D image data, image data processing, etc., can solve the problems that the template cannot be input in advance, the generation of processing paths cannot be discussed, and the detection of workpieces cannot be realized, etc., to achieve Broad application prospects and economic benefits, low cost, and the effect of speed block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

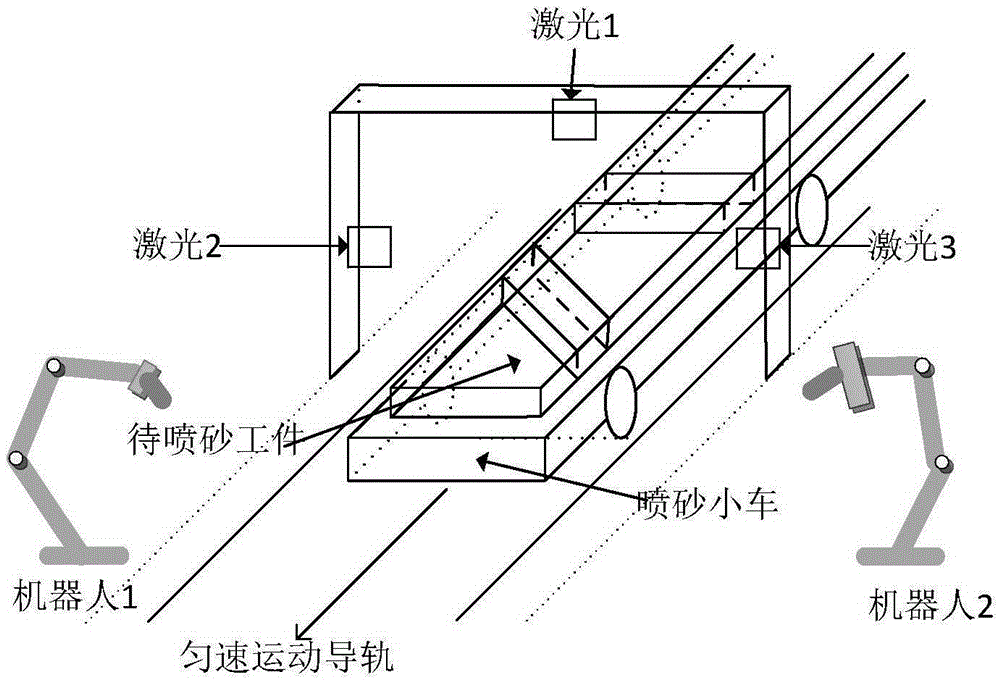

[0061] The technical solutions of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

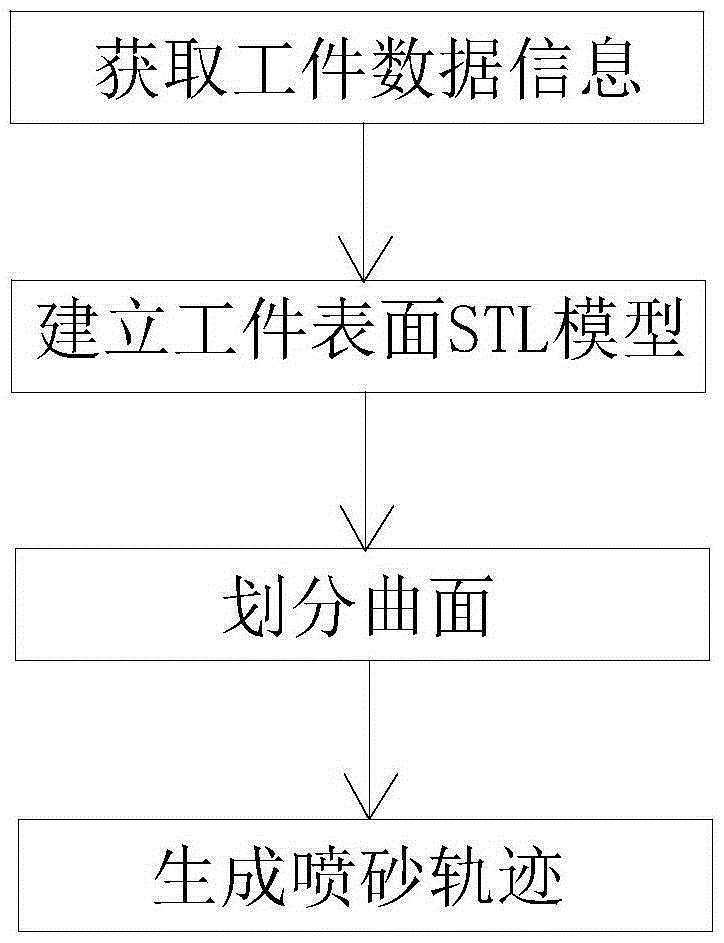

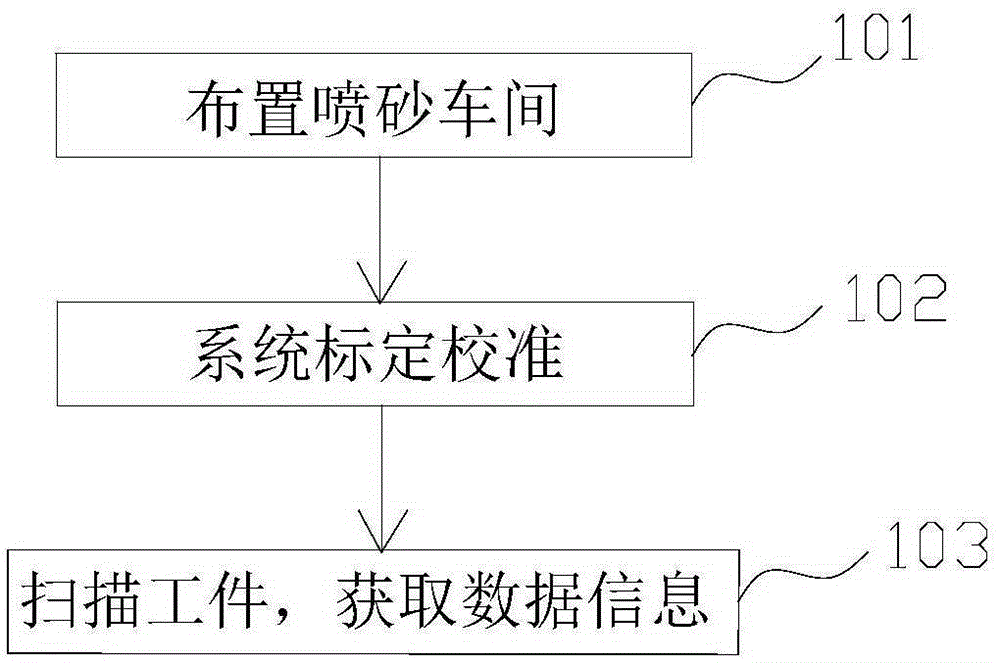

[0062] Such as figure 1 As shown, a method for generating an automatic path of a sandblasting robot based on line laser scanning in an embodiment of the present invention includes the following steps:

[0063] The first step: obtain workpiece data information: use 2D laser scanning to obtain the scanning sampling point data information on the surface of the workpiece to be sandblasted;

[0064] The second step: establish the STL model of the workpiece surface: through point cloud preprocessing, establish the STL model of the surface of the workpiece to be sandblasted;

[0065] Step 3: Divide the surface: extract and use the geometric and topological features of the STL model on the surface of the workpiece to divide the surface of the workpiece into several planes without holes;

[0066] Step 4: Generate sandblasting traj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com