Optical machine adjusting method of R-C reflection and refraction system

A method of installation and adjustment, a folding and reversing technology, applied in installation, optics, optical components, etc., can solve the problems of limited installation and adjustment accuracy, low precision, complicated installation and adjustment process, etc. The effect of improving the accuracy of assembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

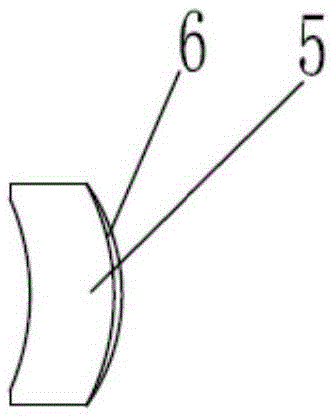

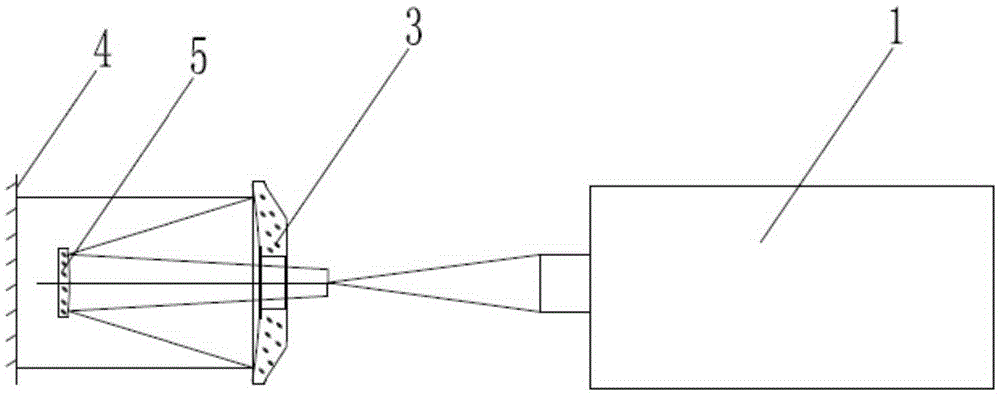

[0031] In the traditional assembly and adjustment process of the R-C catadioptric system, it is first necessary to use the interferometric method to determine the position of the primary mirror. figure 2 As shown, after the position of the primary mirror is determined by the interferometer 1 and the compensator 2, the interferometer 1 is disassembled and moved to the other side of the primary mirror to determine the position of the secondary mirror. image 3 As shown, an interferometer, a primary mirror 3 and a plane mirror 4 are included to determine the position of the secondary mirror 5 . The present invention firstly redesigns the back surface of the secondary mirror, and coats a reflective film 6 on the back of the secondary mirror, so that the back of the secondary mirror coincides with the spherical center image of the secondary mirror reflective surface, and the change of the spherical center image of the secondary mirror reflective surface is consistent with that of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com