Detection apparatus for wane defect of rectangular bamboo splint

A defect detection and bamboo chip technology, applied in measuring devices, material analysis by optical means, instruments, etc., to achieve the effect of stable working performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

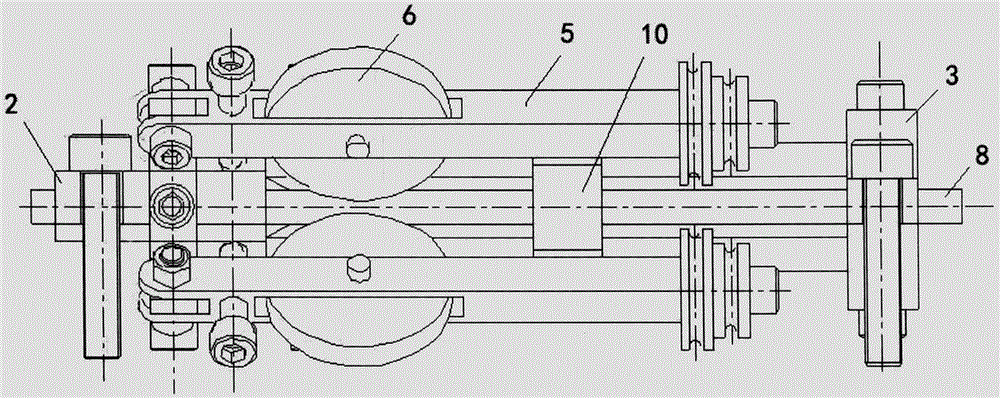

[0015] The defect detection device for rectangular bamboo chips includes a front baffle 2 and a back baffle 3, two legs 1 are respectively arranged on both sides of the front baffle 2 and the back baffle 3, and the front baffle 2 and the back baffle 3 are both Have the rectangular hole that can pass rectangular bamboo slice 8, be fixed with two horizontal direction guide bars 9 up and down between the front baffle plate 2 and the rear baffle plate 3, be fixed with left and right direction guide blocks 10 in the middle of the horizontal direction guide bar 9, horizontal The direction guide bar 9 is respectively provided with bracket ears 4 in the upper left, lower left, upper right, and lower right directions. The four bracket ears 4 are respectively hinged with detection levers 5. The middle part of the detection lever 5 is slotted, and the detection roller 6 is supported by a rotating shaft in the groove. , the detection lever 5 other end is provided with reel 7, and the radiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com