Multi-head Energy Dissipating Barge Device for Large Flow Cutter Suction Ship

A cutter-suction ship with high flow rate, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. It can solve the problems of occupying a large water area, affecting navigation, and not being able to discharge long-distance. Achieve the effects of reducing the occupied space, accelerating the precipitation speed and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

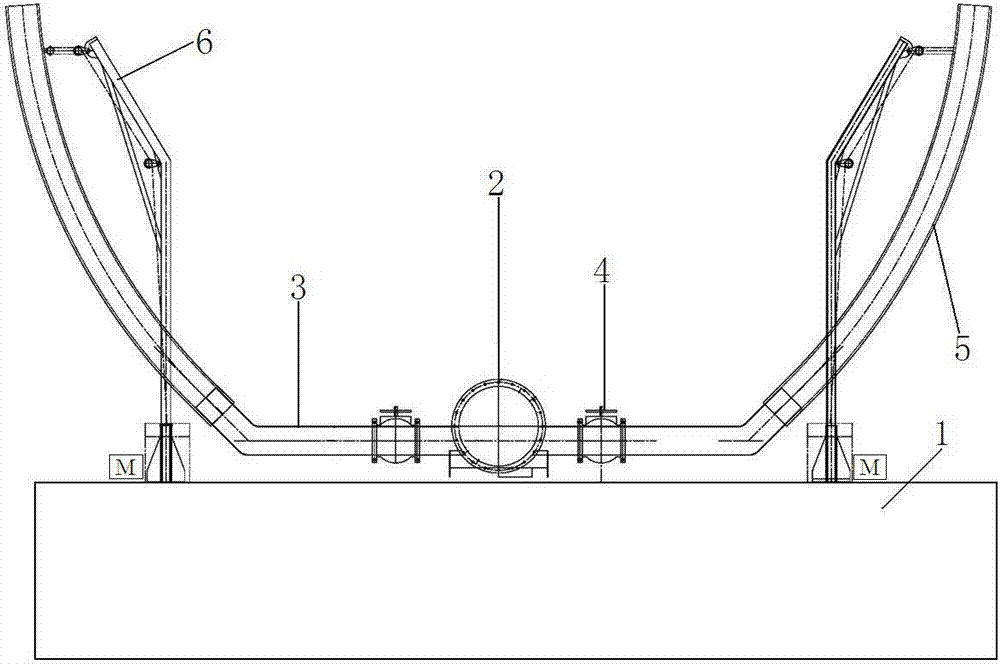

[0023] Refer to attached Figure 1~2 The multi-head energy-dissipating barge device for large-flow cutter suction ships includes an installation platform 1, a main pipe 2, a mud outlet pipe 3, a control valve 4, a mud outlet hose 5, a liftable support 6, a multi-purpose mud outlet 7 and control Valve two 8.

[0024] The installation platform 1 is a floating pontoon, and a liftable support 6 is installed on the upper surface of the installation platform 1. The main pipeline 2 is placed on the upper end surface of the installation platform 1, and mud outlet pipes 3 are arranged on both sides of the main pipeline 2 pipe walls. The outer end of mud pipe 3 is covered with a mud hose 5, and the mud hose 5 is hung on the lower end of the liftable support 6 by a steel wire, and the steel wire is wound on the pulley of the liftable support 6, and a Motor, the tail end of steel wire is connected on the motor output shaft, controls the lifting of mud hose 5 by motor.

[0025] A control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com