Pipe pile-anchor composite foundation and construction technology that can bear bidirectional load in tension and compression

A composite foundation, two-way load technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as unsatisfactory mechanical performance of tensile piles, increased pile density on the bottom surface of building foundations, and reduced building structure reliability. , to achieve the effect of shortening the difficulty of construction work, reducing the amount of piles used, and improving the fatigue resistance of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

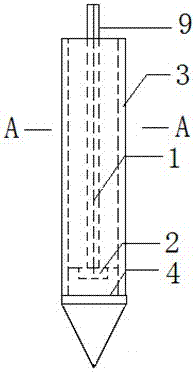

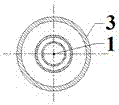

[0052] Such as Figure 4 , Figure 5 As shown, a pipe pile-anchor composite foundation that can bear tension and compression bidirectional loads is embedded and fixed under the base plate 7 of the building structure, including pipe piles 3 and anchor bolts arranged in the cavity of the pipe pile 3. Anchor holes are reserved in the base plate 7, and tension end anchors 6 are pre-embedded in the anchor holes.

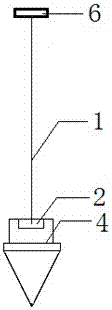

[0053] Such as figure 1 As shown, the anchor rod is composed of a steel anchor cable 1 and a prefabricated anchor head 4 fixed to the lower end of the anchor cable 1 through a fixed-end anchor 2, and the prefabricated anchor head 4 is buried in the soil below the foundation floor 7 , the upper end of the anchor cable 1 passes through the pipe pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com