Water-borne wood paint and preparation method thereof

A water-based wood paint, water-based acrylic technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor wear resistance and chemical resistance, poor fullness, low hardness, etc., and achieve smooth coating film. Plump, reduce the number of construction passes, and dry quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 A kind of water-based wood lacquer and preparation method thereof

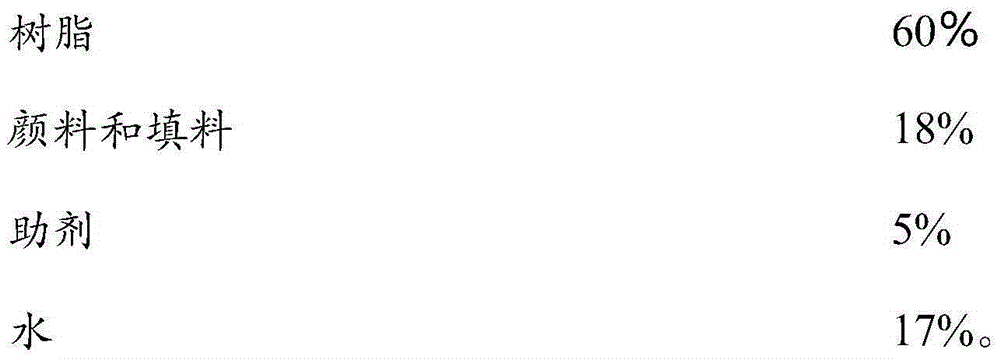

[0029] The formula of the water-based wood paint of the present embodiment is as shown in Table 1.

[0030] Formulation of table 1 waterborne wood lacquer

[0031] serial number

[0032] The preparation method of the water-based wood paint of the present embodiment may further comprise the steps:

[0033] (1) Accurately weigh acrylate-modified polyurethane aliphatic cross-linked resin and acrylic resin, add titanium dioxide and water under 600rpm stirring condition, disperse at 1000-1500rpm for 25-30min until the fineness is less than 35μm, and then add anti-corrosion Agents, pH regulators, film-forming aids, leveling agents, dispersed at 1000rpm for about 10 minutes;

[0034] (2), adjust the speed to 800rpm, add thickener to adjust the viscosity to 35±3s (coat 4 cups) and defoam slowly for 10 minutes;

[0035] (3) After passing the inspection, use 200-mesh filter cloth to filt...

Embodiment 2

[0040] Embodiment 2 A kind of water-based wood lacquer and preparation method thereof

[0041] The formula of the water-based wood paint of the present embodiment is as shown in Table 3.

[0042] Formulation of table 3 waterborne wood lacquer

[0043] serial number

[0044] 5

[0045] The preparation method of the water-based wood lacquer of the present embodiment is the same as that of Example 1.

[0046] The main performance indicators of the water-based wood paint of Example 2 are detected, and the detection results are shown in Table 4.

[0047] The main performance index detection result of the water-based wood lacquer of table 4 embodiment 2

[0048] performance

[0049] As can be seen from the results in Table 4, the performance index of the water-based wood lacquer of the present embodiment is equivalent to that of the water-based wood lacquer of Example 1.

Embodiment 3

[0050] Embodiment 3 A kind of water-based wood lacquer and preparation method thereof

[0051] The formula of the water-based wood paint of the present embodiment is as shown in Table 5.

[0052] Formulation of table 5 waterborne wood lacquer

[0053] serial number

[0054] 1

[0055] The preparation method of the water-based wood lacquer of the present embodiment is the same as that of Example 1.

[0056] The main performance indicators of the water-based wood paint of Example 3 were tested, and the test results are shown in Table 6.

[0057] The main performance index detection result of the water-based wood paint of table 6 embodiment 3

[0058] performance

[0059] As can be seen from the results in Table 6, the performance index of the water-based wood lacquer of the present embodiment is equivalent to that of the water-based wood lacquer of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com