Dense flint optical glass and preparation method thereof

A technology of optical glass and heavy flint, which is applied in the field of heavy flint optical glass and its preparation, can solve the problems of unfavorable promotion and achieve good transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

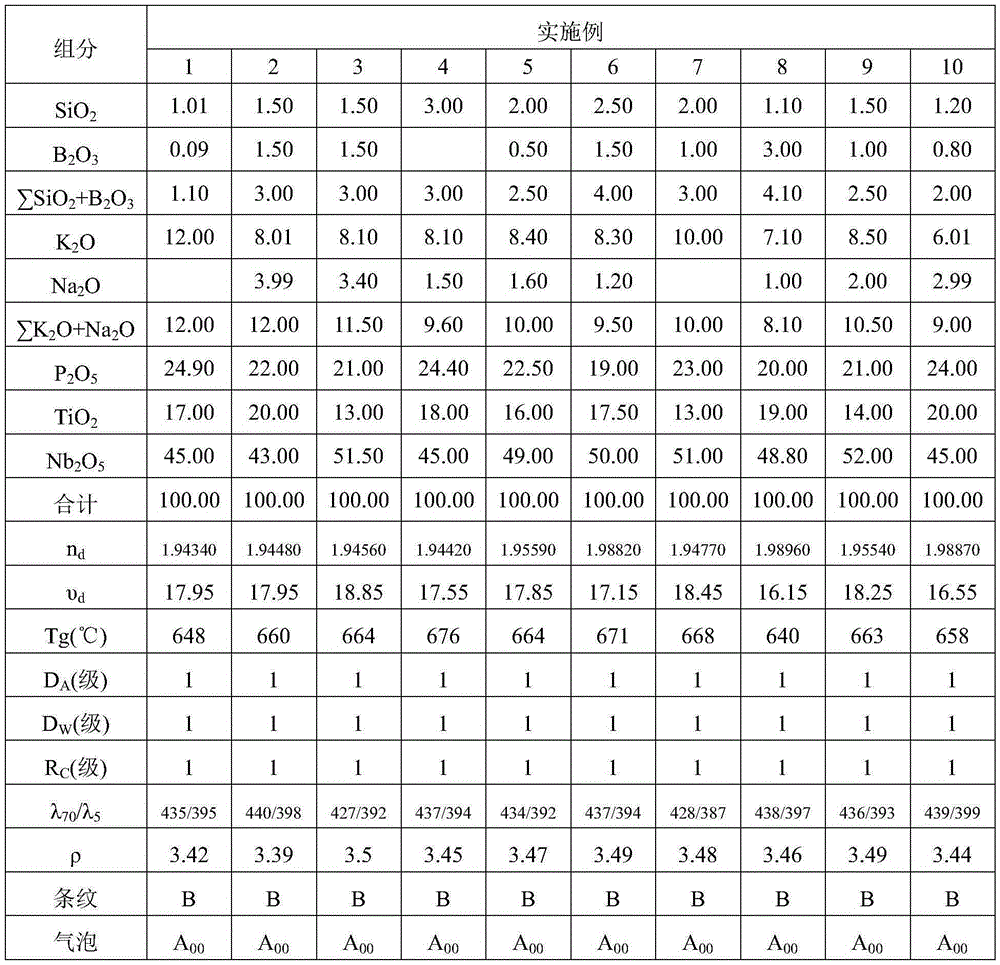

[0073] Table 1: Glass components and performance parameters of Examples 1-10

[0074]

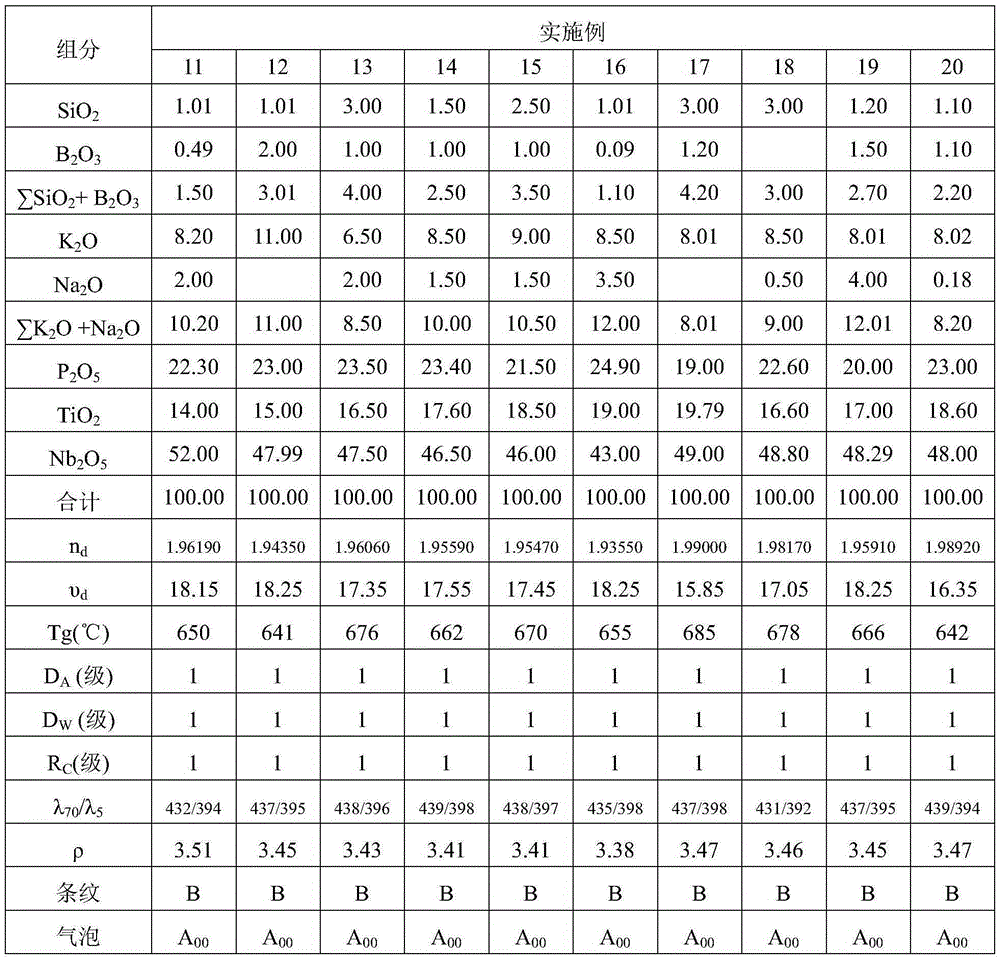

[0075] Table 2: Glass components and performance parameters of Examples 11-20

[0076]

[0077] Table 3: Glass composition and performance parameters of Comparative Examples A-E

[0078]

[0079] Table 4: Optical difference table of Example 5

[0080]

1st pot

2nd pot

3rd pot

Pot 4

5th pot

nd

1.95590

1.95595

1.95574

1.95585

1.95599

υ d

17.85

17.88

17.84

17.86

17.87

[0081] Remarks: n in Table 1-4 d , Υ d All are the values after annealing at -25°C.

[0082] The raw materials corresponding to the components of the 20 examples listed in Table 1 and Table 2, such as oxides, carbonates, nitrates, fluorides, metaphosphates, etc., are weighed according to the specified ratios, and the temperature is at 1250°C. It is added to the platinum crucible at temperature, after melting, ventilating (1270°C nitrogen gas for 5 hours), stirring, clarification, and homogenization process, after cooling to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com