Capping and capping two-in-one manipulator and method for capping and capping

A two-in-one, manipulator technology, used in the packaging industry in the fields of flammability and corrosion resistance, highly toxic and explosive fields, to ensure the pass rate, improve the cost performance, and solve the problem of airtightness detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

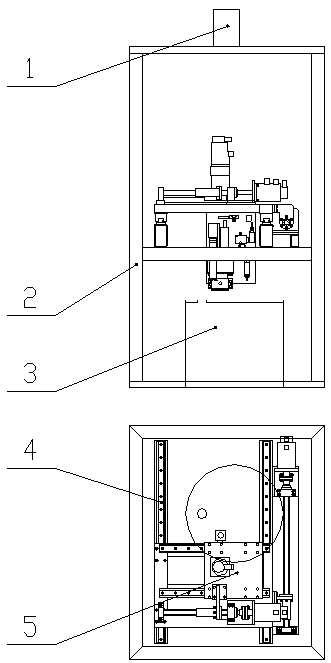

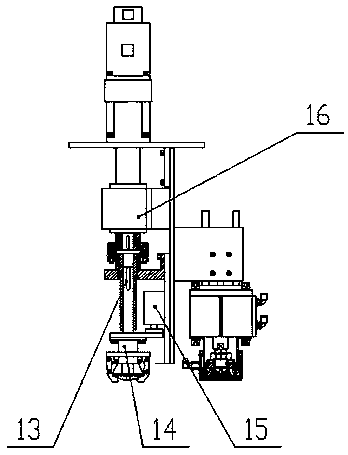

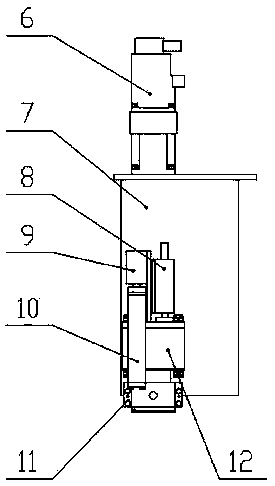

[0024] Such as figure 1 As shown, a cap screwing and capping two-in-one manipulator includes a visual addressing system 1 and a cross coordinate trolley 4 installed on the main frame 2 shown and connected by bolts. The cap screwing and capping device 5 is installed on the shown cross coordinate trolley 4 and connected by bolts. The shown cross coordinate trolley 4 is driven by a servo motor to position and transport the shown capping and capping device 5 to a designated position. The shown screw cap and capping device 5 are composed of the shown servo motor 6, mounting base 7, capping cylinder 8, airtight detection cylinder 9, airtight detection bracket 10, airtight device 11, capping device 12, spline shaft 13. The capping device 14, the capping cylinder 15, and the moment sensor 16 are driven by the cross coordinate trolley 4 as a whole, and the capping and closing actions are completed in sequence, wherein the capping device 14 is installed on the capping device 12 shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com