Sealing performance detecting device of cylindrical part

A sealing detection and cylinder technology, which is applied in the field of sealing detection devices for cylinders, can solve problems such as difficulty in meeting detection requirements, and achieve the effects of solving sealing detection problems, reducing measurement errors and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

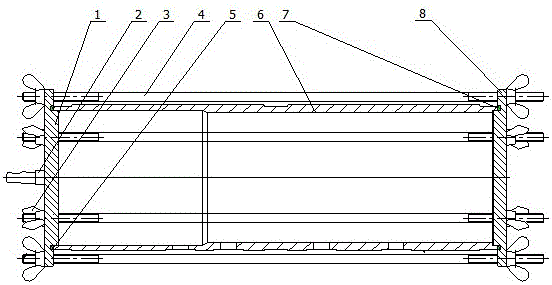

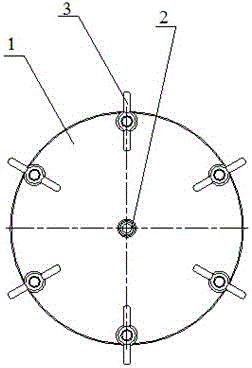

[0017] The airtightness detection device for the tubular parts of the present invention will be described in detail below in conjunction with the accompanying drawings and the embodiments:

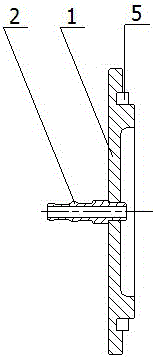

[0018] Such as Figure 1~3 As shown, a sealing detection device for a cylindrical part includes an upper end cap 1 and a lower end cap 8 installed at both ends of the sleeve 6, and an annular groove is formed at the contact between the upper end cap 1 and the lower end cap 8 and the sleeve 6, An upper sealing ring 5 and a lower sealing ring 7 are respectively arranged in the groove, and a plurality of screw rods 4 are evenly distributed on the outside of the sleeve 6, and the two ends of the screw rod 4 are respectively fastened to the upper end cover 1 and the lower end cover 8 by wing nuts 3; An air nozzle 2 is arranged at the center of the upper end cover 1 .

[0019] The outer circular wall of the gas nozzle 2 is an inverted zigzag structure.

[0020] Both the upper end cover 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com