Method for manufacturing middle frame of mobile phone and middle frame of mobile phone

A manufacturing method, the technology of the middle frame of the mobile phone, applied in the direction of coating, etc., can solve the problems of long processing time, high production cost, and large production limit of metal shell, so as to shorten the processing time, low cost, stamping Effects in a short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

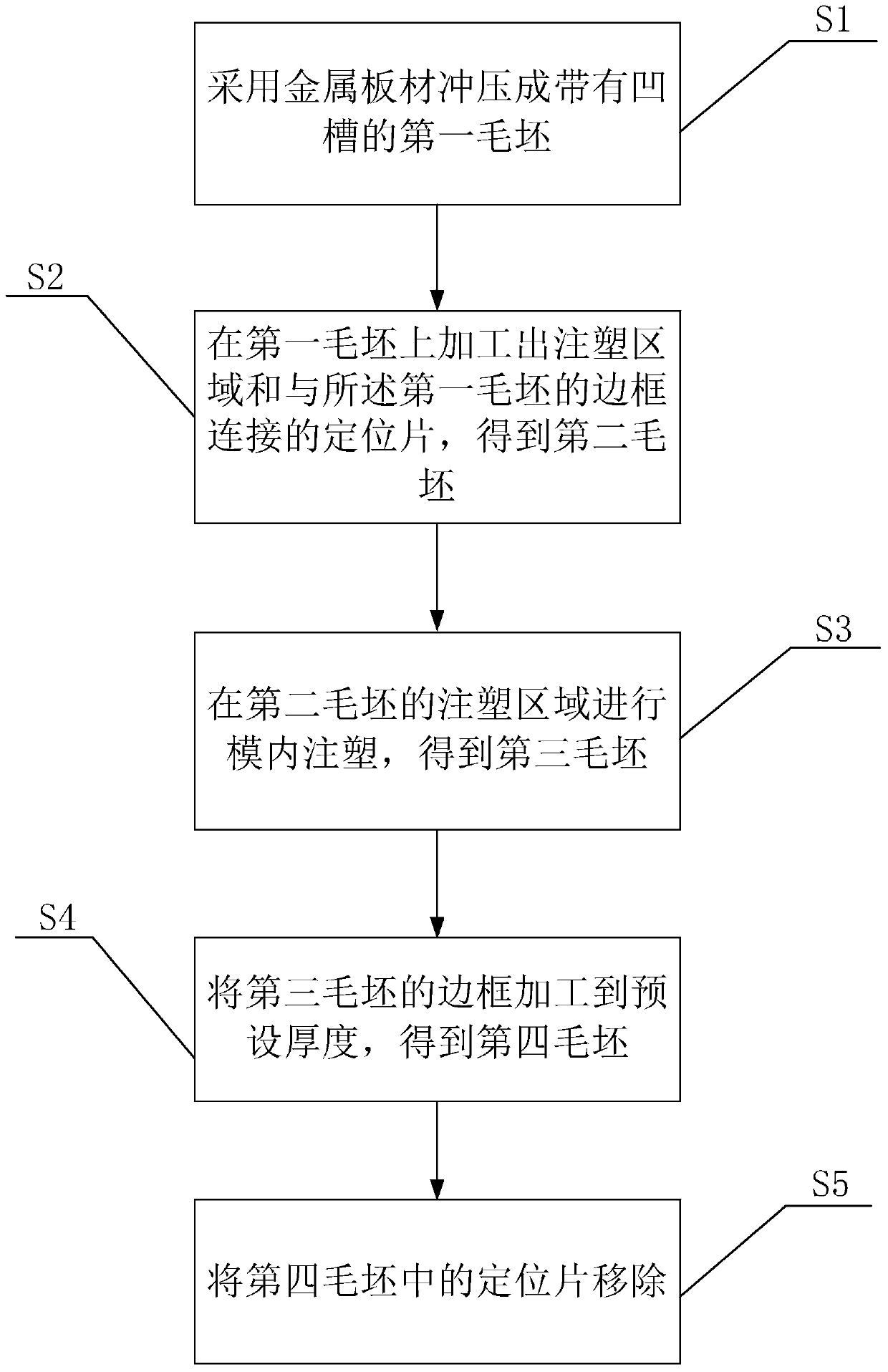

[0033] Such as figure 1 shown, combined with Figure 5 to Figure 7 , a method for manufacturing a mobile phone middle frame in the present embodiment, comprising the following steps:

[0034] S1. Stamping a metal sheet into a first blank with grooves;

[0035] S2. Process the injection molding area and the positioning piece connected to the frame of the first blank on the first blank to obtain a second blank;

[0036] S3. Perform in-mold injection molding in the injection molding area of the second blank to obtain a third blank;

[0037] S4. Process the frame of the third blank to a preset thickness to obtain a fourth blank;

[0038] S5, removing the positioning piece in the fourth blank.

[0039] Firstly, the metal plate is stamped to obtain the first blank with grooves; after that, the injection molding area and the positioning piece connected with the frame of the first blank are processed on the first blank to obtain the second blank; then, in the second The injecti...

Embodiment 2

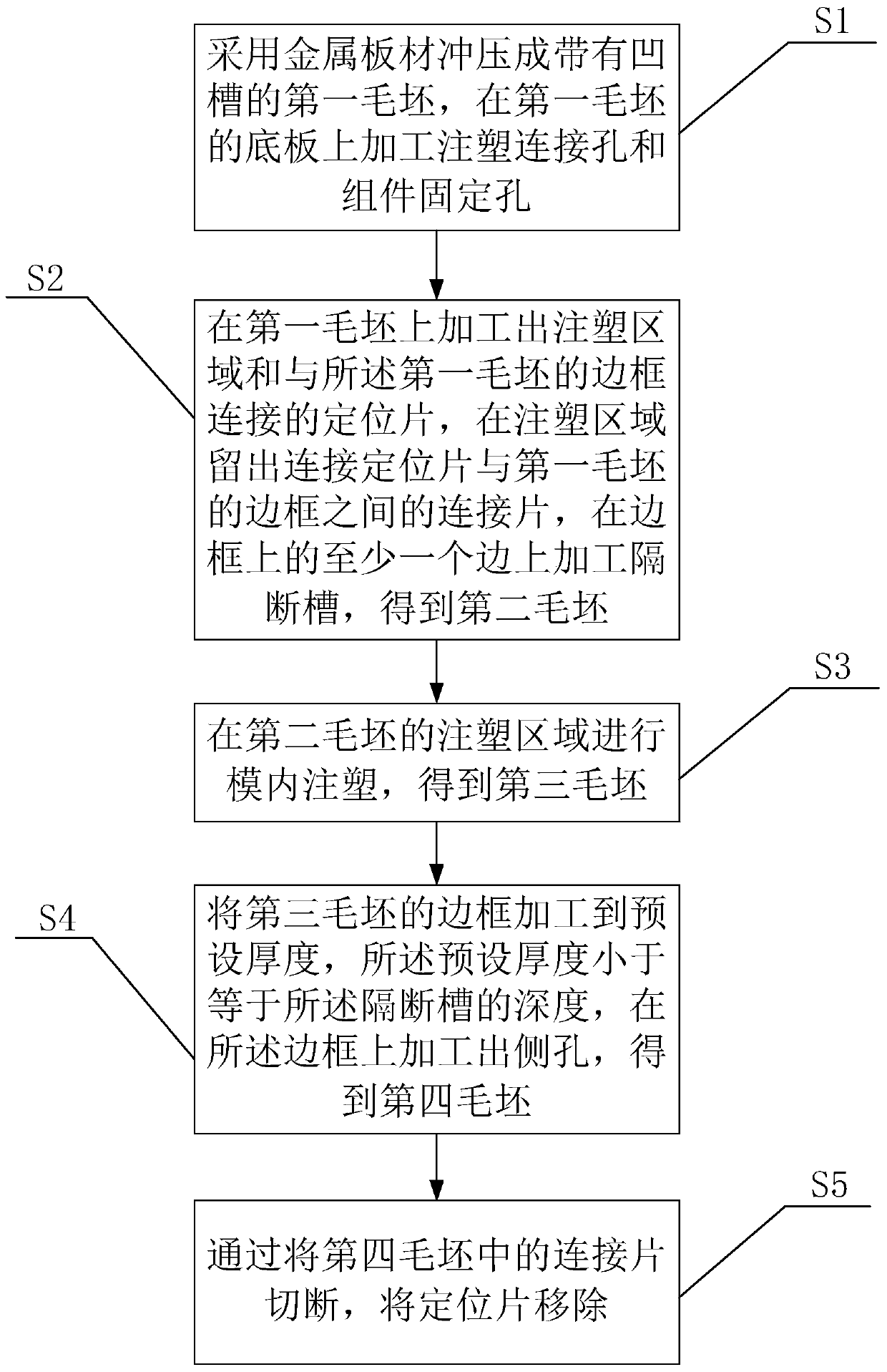

[0042] Such as figure 2 shown, combined with Figure 5 to Figure 7 , a method for manufacturing a mobile phone middle frame in the present embodiment, comprising the following steps:

[0043] S1. Stamping a metal sheet into a first blank with grooves, and processing injection molding connection holes and component fixing holes on the bottom plate of the first blank;

[0044] S2. Process the injection molding area and the positioning piece connected to the frame of the first blank on the first blank, leave a connecting piece between the positioning piece and the frame of the first blank in the injection molding area, at least on the frame Cutting grooves are processed on one side to obtain the second blank;

[0045] S3. Perform in-mold injection molding in the injection molding area of the second blank to obtain a third blank;

[0046]S4. Machining the frame of the third blank to a preset thickness, the preset thickness being less than or equal to the depth of the partiti...

Embodiment 3

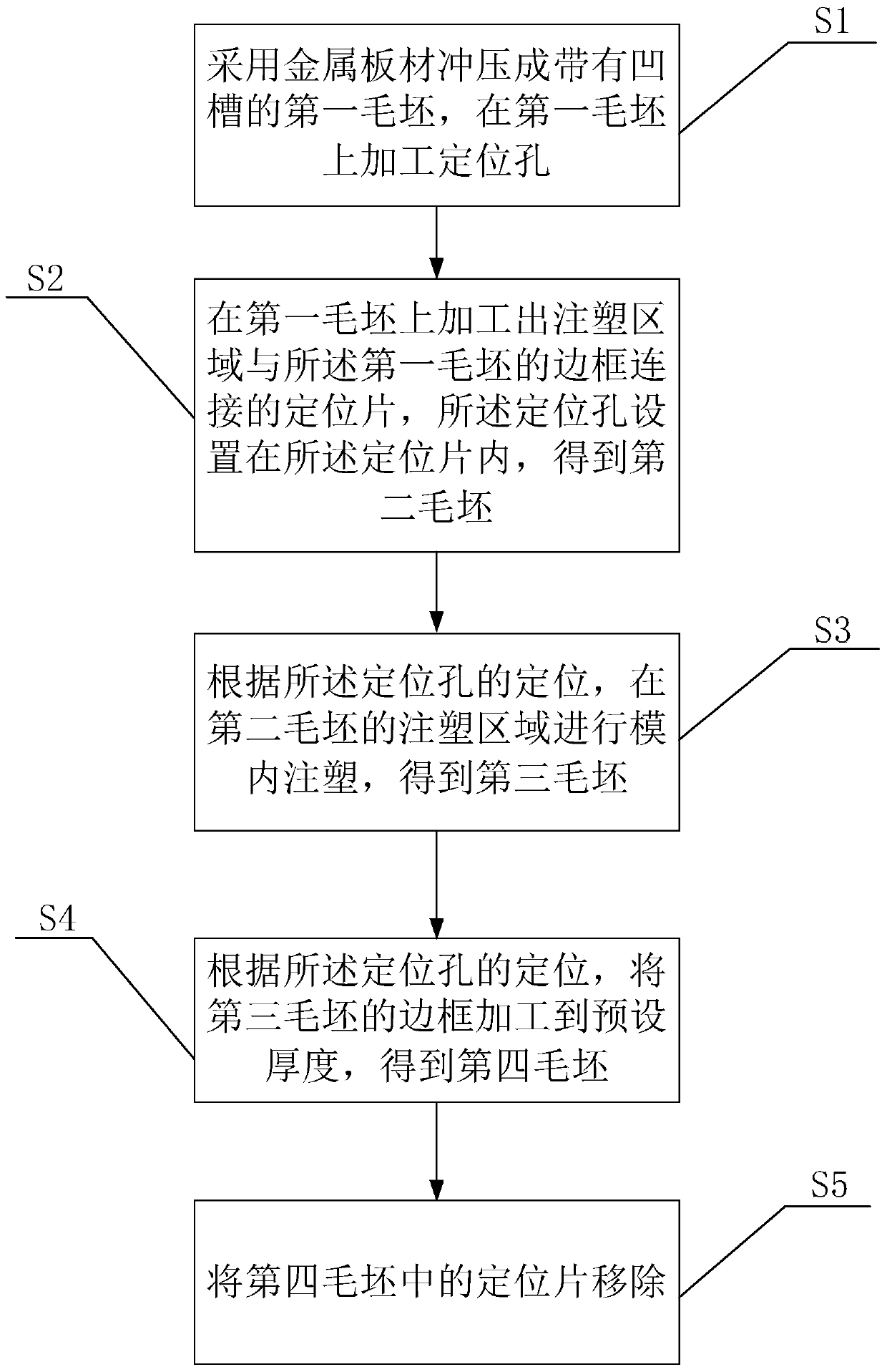

[0055] Such as image 3 shown, combined with Figure 5 to Figure 7 , a method for manufacturing a mobile phone middle frame in the present embodiment, comprising the following steps:

[0056] S1. Stamping a metal plate into a first blank with grooves, and machining positioning holes on the first blank;

[0057] S2. Process a positioning piece on the first blank that connects the injection molding area to the frame of the first blank, and the positioning hole is set in the positioning piece to obtain a second blank;

[0058] S3. According to the positioning of the positioning holes, perform in-mold injection molding in the injection molding area of the second blank to obtain a third blank;

[0059] S4. According to the positioning of the positioning holes, process the frame of the third blank to a preset thickness to obtain a fourth blank;

[0060] S5, removing the positioning piece in the fourth blank.

[0061] In this embodiment, in addition to the effect of Embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com