Planar permanent-magnetic working table

A permanent magnet workbench and plane technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of time-consuming, labor-intensive, small suction, limited use occasions, etc., to achieve a compact overall structure and improve the holding force , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

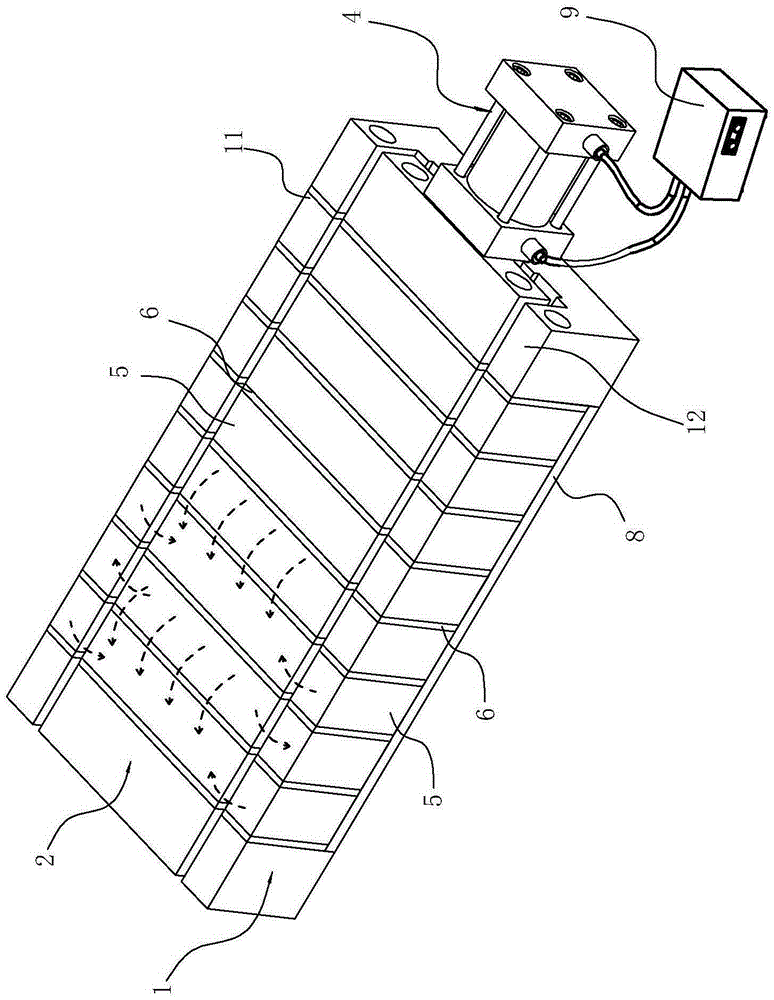

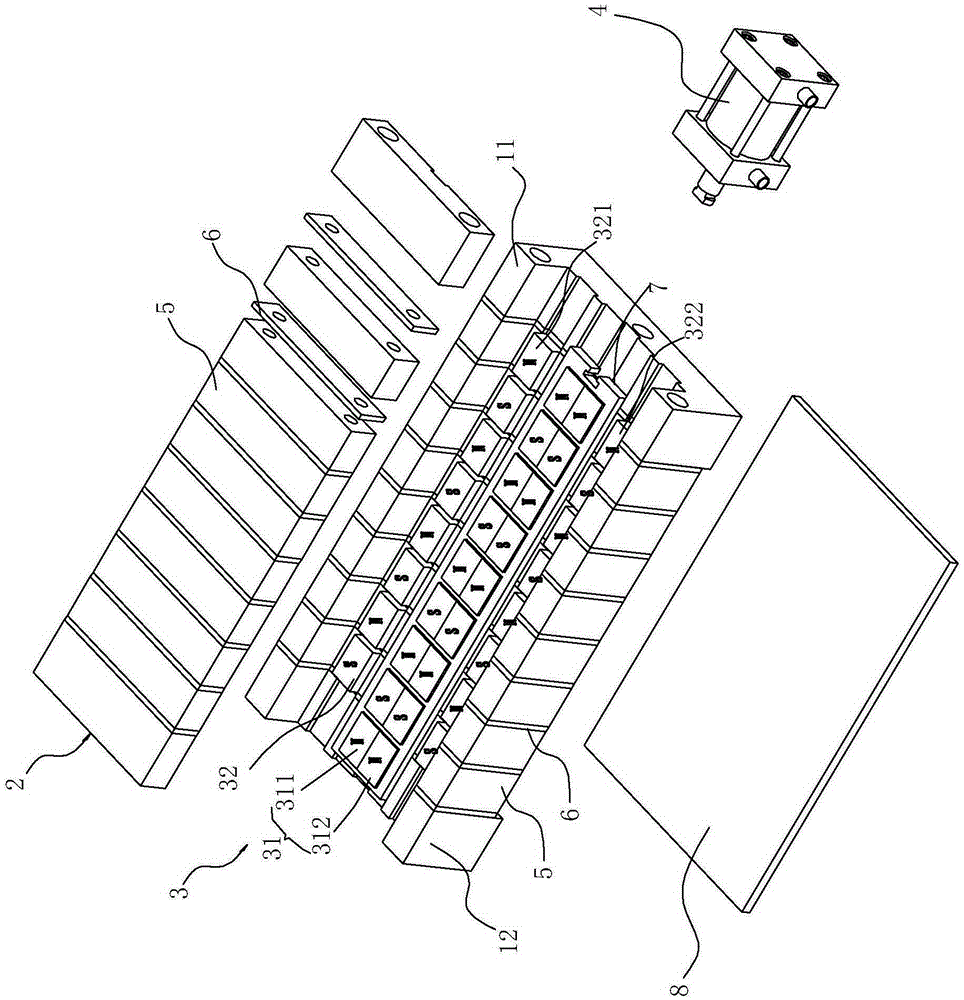

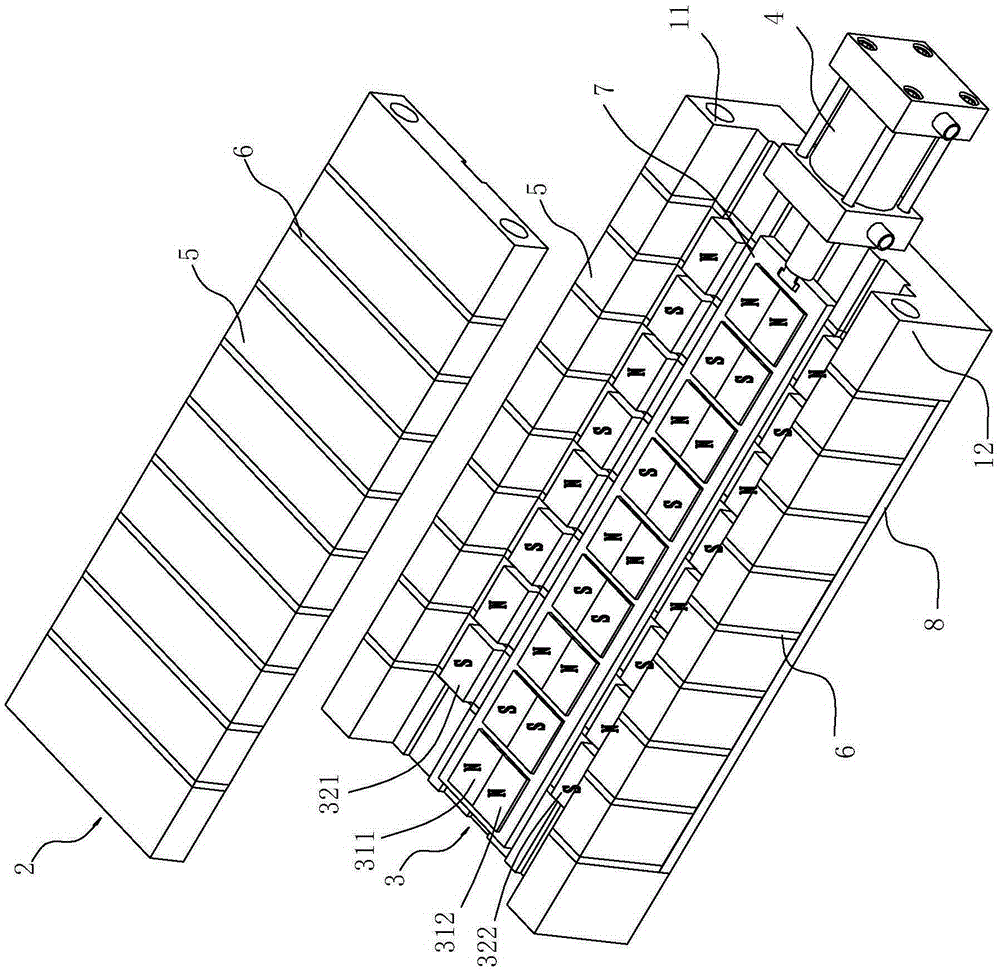

[0018] Such as Figure 1~4 As shown, the planar permanent magnet workbench includes a housing 1, a panel 2, a pole core plate 3 located in the housing 1 below the panel 2, and a driving mechanism, wherein the housing 1 and the panel 2 include magnetically conductive magnets arranged at intervals. Block 5 and magnetic isolation block 6; the drive mechanism adopts hydraulic cylinder 4 and a hydraulic station 9 for supplying oil to hydraulic cylinder 4; pole core plate 3 includes a plurality of bottom magnets 31 arranged longitudinally and adjacent to opposite polarities and at least A plurality of side magnets 32 located on one side of the bottom magnet 31 . In the present embodiment, a plurality of bottom magnets 31 are selected as nine bottom magnets 31, and each bottom magnet 31 is fixed on a bottom plate 7 in a longitudinally spaced manner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com