Small excavator covering part overturning tool and using method thereof

A technology for flipping tooling and covering parts, which is applied in metal processing, connecting components, manufacturing tools, etc. It can solve the problems of uneven surface of sponges and heat insulation pads, lower production efficiency, and inconvenient pasting, so as to ensure firm pasting and flatness, reliable and fast component installation, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

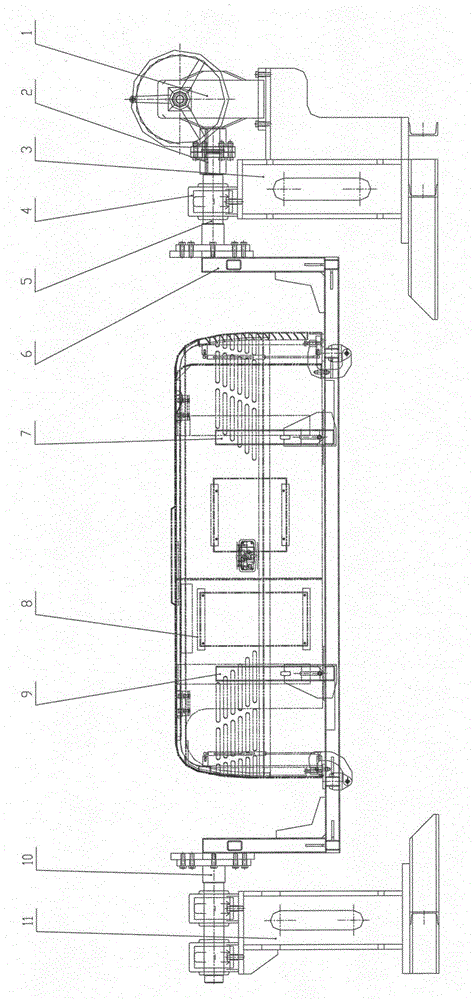

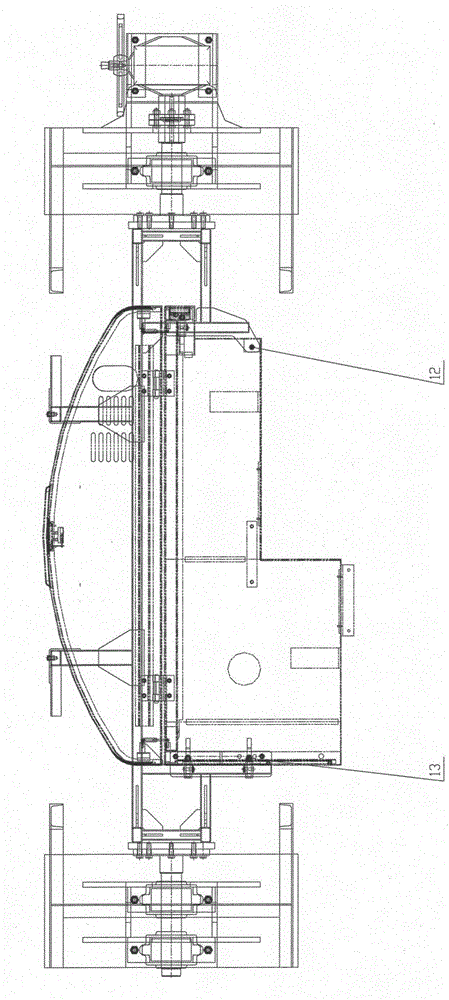

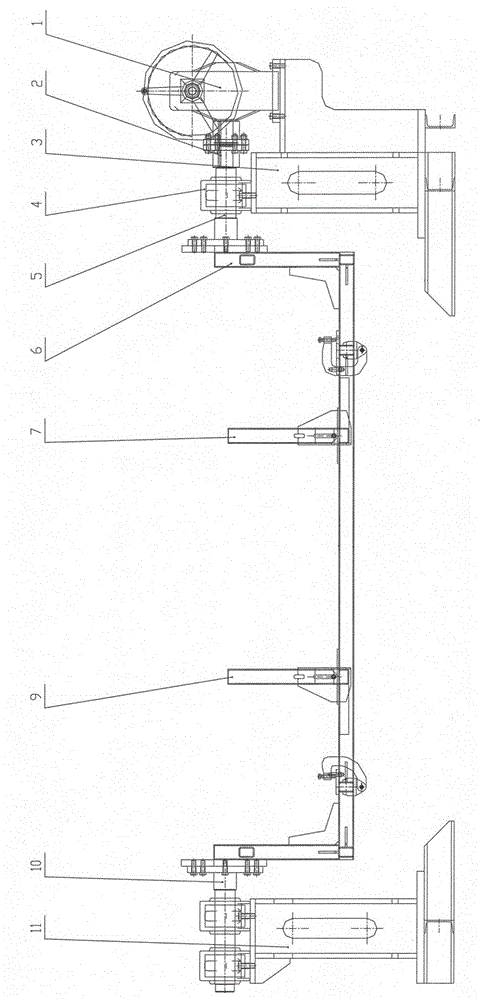

[0025] figure 1 and figure 2 Respectively, the front view and the top view of the overall structure of the small excavator cover turning tooling provided by the present invention, image 3 and Figure 4 They are respectively the front view and the top view of the overturning tool when the cover is not installed. The cover overturning tool for the small excavator includes left and right supports 11, 3, and the left and right supports 11, 3 are respectively equipped with a bearing seat 4 and a reducer 1 Installed on the right support 3, one end of the overturning drive shaft 5 is connected to the output end of the reducer 1 through the coupling 2, and the other end is connected to the overturning body 6 through the bearing seat 4 on the right support 3, and the overturning driven shaft One end of 10 passes through the bearing se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com