Center hole benchmark correcting method reducing cutting torque

A technology of cutting torque and center hole, which is applied in the field of center hole datum correction to reduce cutting torque, can solve problems such as discomfort, discomfort and difficulty in clamping and positioning, and achieve the effect of reducing waste and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0030] A kind of central hole datum correction method that reduces cutting torque of the present invention comprises the following steps:

[0031] 1) Select the center hole datum correction process in the machining process of typical blade parts such as journals.

[0032] 2) Select the reference process equipment for processing and correcting the center hole.

[0033] 3) Select fixtures and equipment, as well as fixtures and parts positioning datum.

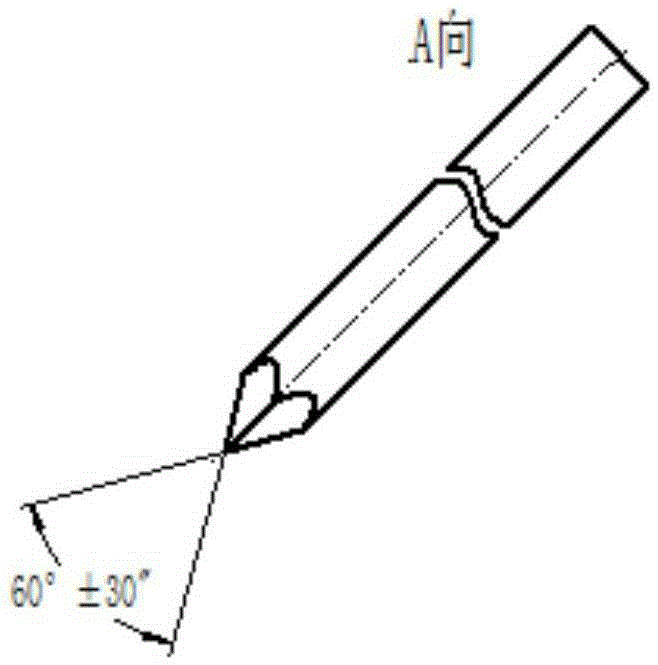

[0034] 4) Design a special tool for center hole reference correction to reduce cutting torque.

[0035] 5) Detect the actual value of the coaxiality tolerance of the heat treatment of the journal blade machining process and the center hole reference before semi-finishing, and calculate the average value after multiple measurements.

[0036] 6) Trial machining, using a special center hole benchmark c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com