Sliding box feeding type mixing tank

A technology of mixing tank and box body, applied in mixers, mixers with rotary stirring devices, dissolving and other directions, can solve the problem of wrong feeding order and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

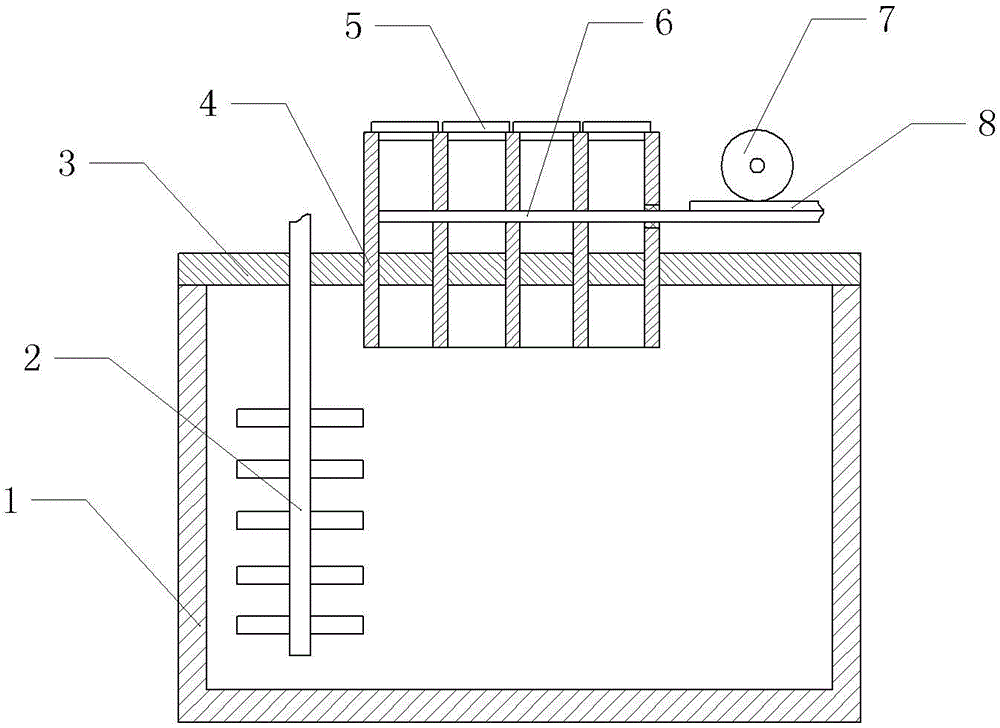

[0017] The reference signs in the accompanying drawings of the specification include: tank body 1 , stirring paddle 2 , cover 3 , feeding tube 4 , tube cover 5 , inserting plate 6 , gear 7 , and rack 8 .

[0018] Such as figure 1 As shown, the pulling box body feeding type mixing tank includes a tank body 1, a stirring paddle 2 is arranged in the tank body 1, a cover 3 is provided on the upper end of the tank body 1, and the cover 3 is horizontal; There are multiple vertical feeding tubes 4, the feeding tubes 4 are square, and the upper end of the feeding tubes 4 is provided with a cap 5, and the multiple vertical feeding tubes 4 are arranged in a straight line, and the multiple vertical feeding tubes 4 are integrally formed , the outer wall of each feeding pipe 4 is provided with a marking layer, and the marking layer from left to right is marked with the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com