Horizontal-type dual-inlet pressurization rotating packing bed

A rotating packed bed, double inlet technology, applied in chemical/physical/physical-chemical mobile reactors, dispersed particle separation, fractionation, etc., can solve the problems of unstable operation, small processing capacity, low efficiency, etc., and achieve operating costs. Low, large processing capacity, the effect of reducing installed power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

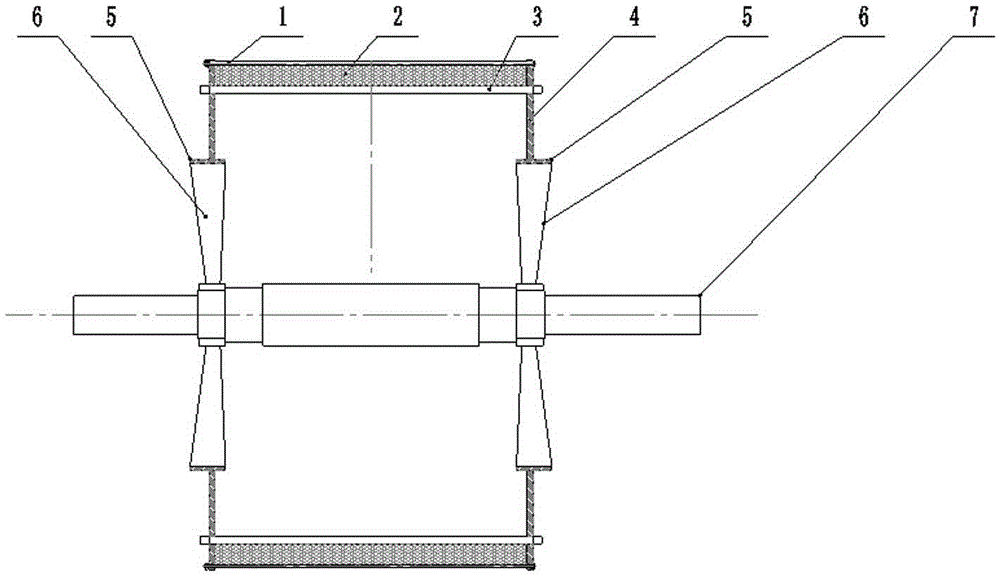

[0018] Such as figure 1 The horizontal double-inlet pressurized rotary packed bed shown includes a packing rotor and a drive shaft 7 fixed coaxially and horizontally in a cylindrical cylinder, side plates 4, inlet pipe joints 5, and vane groups 6; the packing rotor It is composed of pressure rod 1, packing layer 2 and strut 3. The packing layer 2 is fixed between the pressure rod 1 and the strut 3. The side plates 4 are fixed on both ends of the filling rotor along the circumference. The blade groups 6 are two groups, showing The two ends of the transmission shaft 7 are fixed in a radial arrangement, and the end of the blade group 6 is connected with the inlet pipe section 5 .

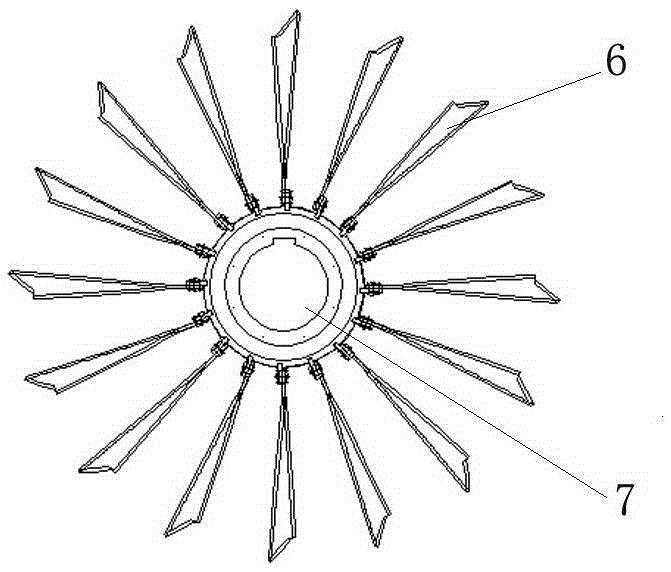

[0019] Such as figure 2 As shown, the geometric shape of the blades of the blade group 6 is adjustable, and different airfoils are distributed according to different twist angles and chord length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com