Method for manufacturing rubrene film based on double layer induction technology

A technology of rubrene, technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of complex process and poor film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

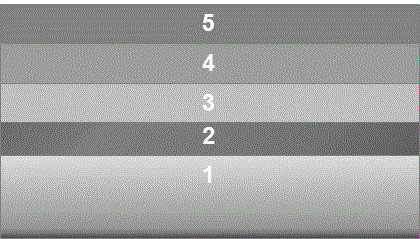

[0007] Such as figure 1 Shown, Si substrate (1), SiO 2 Insulation layer (2), p-type hexabiphenyl (p-6P) first inducing layer (3), α-4 thiophene (α-4T) second inducing layer (4), rubrene active layer (5) . Among them, the insulating layer thickness is 300nm SiO 2 (2).

[0008] The specific realization process: The substrate consists of a base Si (1) and a layer of 300nm thick SiO attached to its surface 2 (2) Composition; clean the substrate and put it into the reaction chamber of the seven-station OEL / EL photoelectric thin film joint preparation system; the vacuum of the reaction chamber is pumped to less than 6.0×10 -4 Pa; the first induction layer p-6P(3) is vacuum-evaporated on the substrate, the substrate temperature is 180℃, and the thickness is about 3nm; the second induction layer α-4T( 4) The substrate temperature is 20°C and the thickness is 30nm; a semiconductor layer rubrene (5) is vacuum-evaporated on the second induction layer, the substrate temperature is 20°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com