RFID based system for monitoring the corrosion of reinforcement in concrete

A steel bar corrosion and monitoring system technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as structural damage, reduced bearing capacity of reinforced concrete members, and reduced ductility, etc., to achieve low power consumption and data The effect of stable transmission and long transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings.

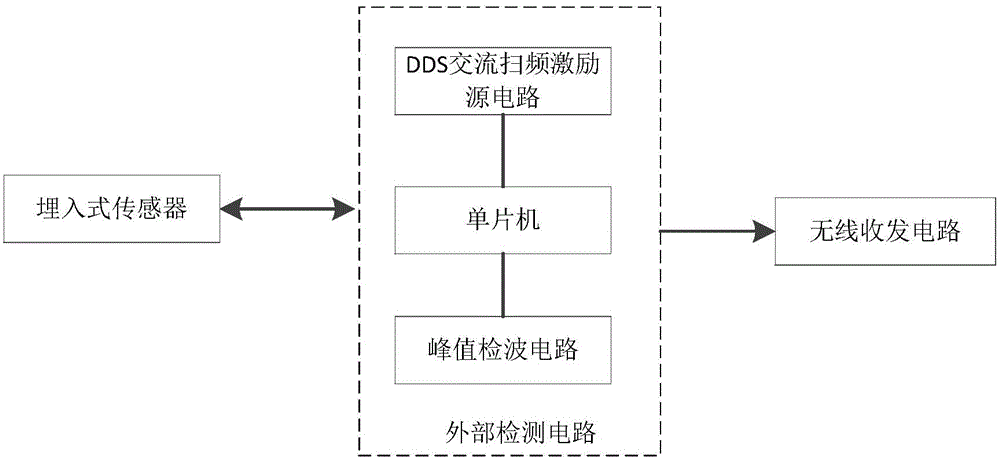

[0015] Such as figure 1 As shown, an RFID-based steel corrosion monitoring system in concrete includes embedded sensors and external circuits; where:

[0016] The embedded sensor is an LC resonant circuit pre-embedded in concrete, and the LC resonant circuit includes several capacitor parallel branches, and each capacitor parallel branch is connected in series with steel bars of different thicknesses;

[0017] The external circuit includes an external detection circuit and a wireless transceiver circuit; wherein the external detection circuit includes a single-chip microcomputer, a DDS AC frequency sweep excitation source circuit and a peak detection circuit;

[0018] The DDS AC frequency sweep excitation source circuit, the DDS AC frequency sweep excitation source sends an oscillating signal with adjustable frequency according to the control of the single-chip microc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com