Cold-expanding, cold-hooping and self-sealing connecting type plastic floor heating pipe fitting

A technology for floor heating pipes and plastics, which is applied in the direction of pipes/pipe joints/fittings, pipe connection arrangements, mechanical equipment, etc., can solve the problems of connection sealing and strength uncertainty, leakage, and difficulty in controlling the timing of fusion and jointing, so as to ensure sealing. and strength, the effect of eliminating hidden dangers of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

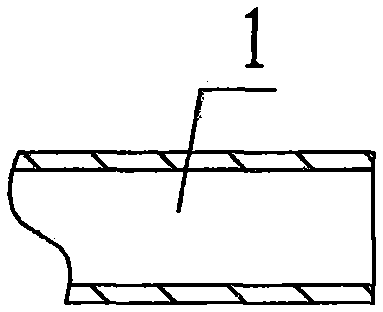

[0028] refer to Figure 1 to Figure 15 , a plastic floor heating pipe fitting for self-sealing connection of cold expansion and cold hoops according to the present invention, comprising a pipe 1, a pipe hoop 2, and a pipe fitting body 3, wherein: the pipe 1 is a cylindrical tubular plastic member;

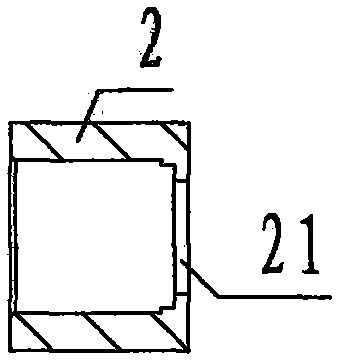

[0029] The pipe collar 2 is a cylindrical tubular plastic member, and the right end of the lumen of the pipe collar 2 is provided with a cylindrical hole-shaped step with an inner diameter smaller than the inner diameter of the right part, which is called a snap ring 21;

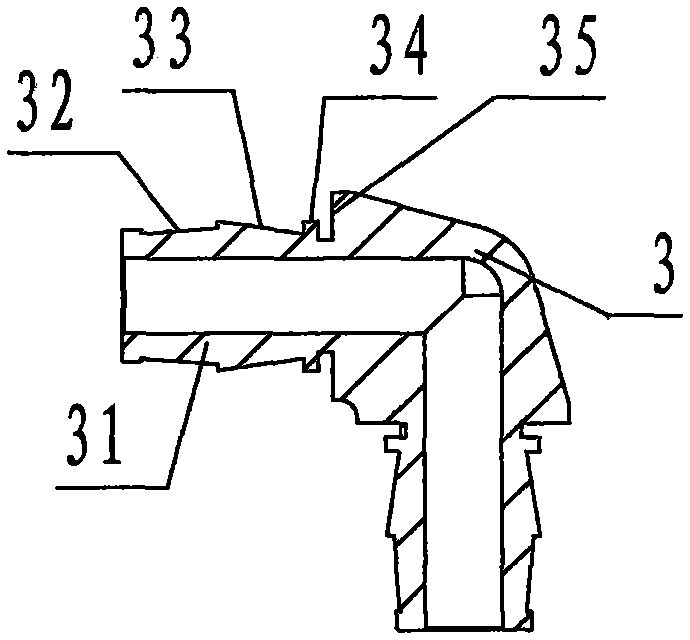

[0030] The pipe fitting body 3 is a plastic member in the shape of a hollow thin-walled pipe. The part connecting the inner cavity of the pipe fitting body 3 to the outside world is called a joint 31. The joint 31 is cylindrical, and the outer walls of the joint 31 are respectively from left to right. Be provided with embedding groove 32, frustum 33, retaining ring 34 and retaining rib 35 structures, described em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com