Corrosion reinforcement and protection method for gis through-wall busbar shell

A technology for through-wall busbar and shell, which is applied in the field of GIS through-wall busbar shell corrosion reinforcement and protection, can solve the problems of shell corrosion and perforation, lack of fire resistance, waterproof, anti-corrosion, sealing function, and increased grid dispatch workload. , to achieve the effect of improving fire resistance and waterproof ability, high degree of shell reinforcement, and eliminating hidden dangers of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

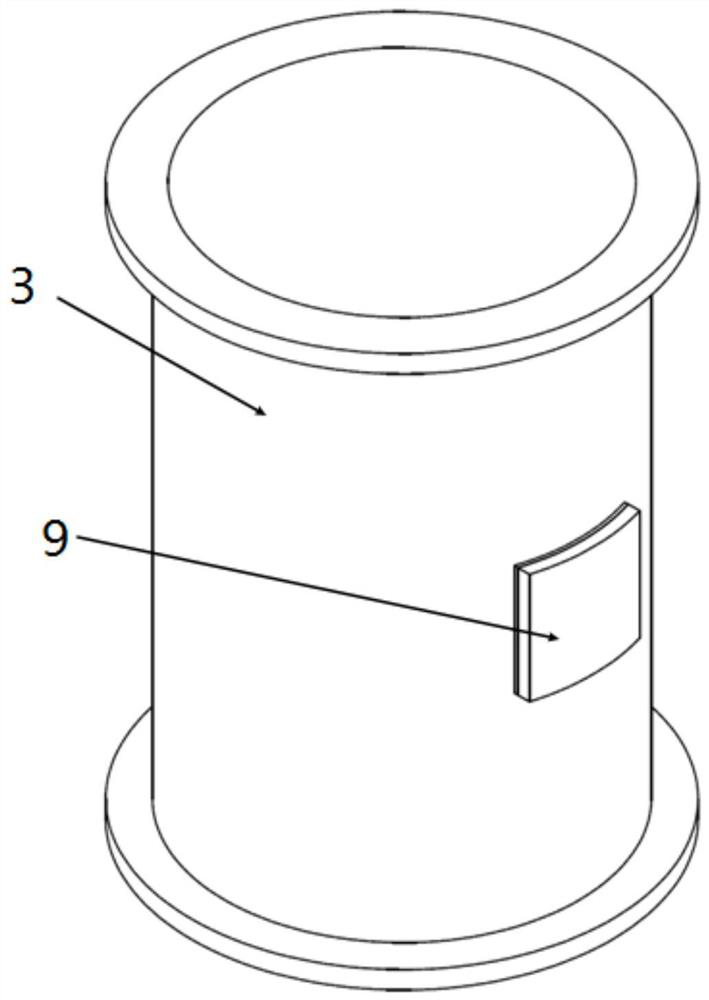

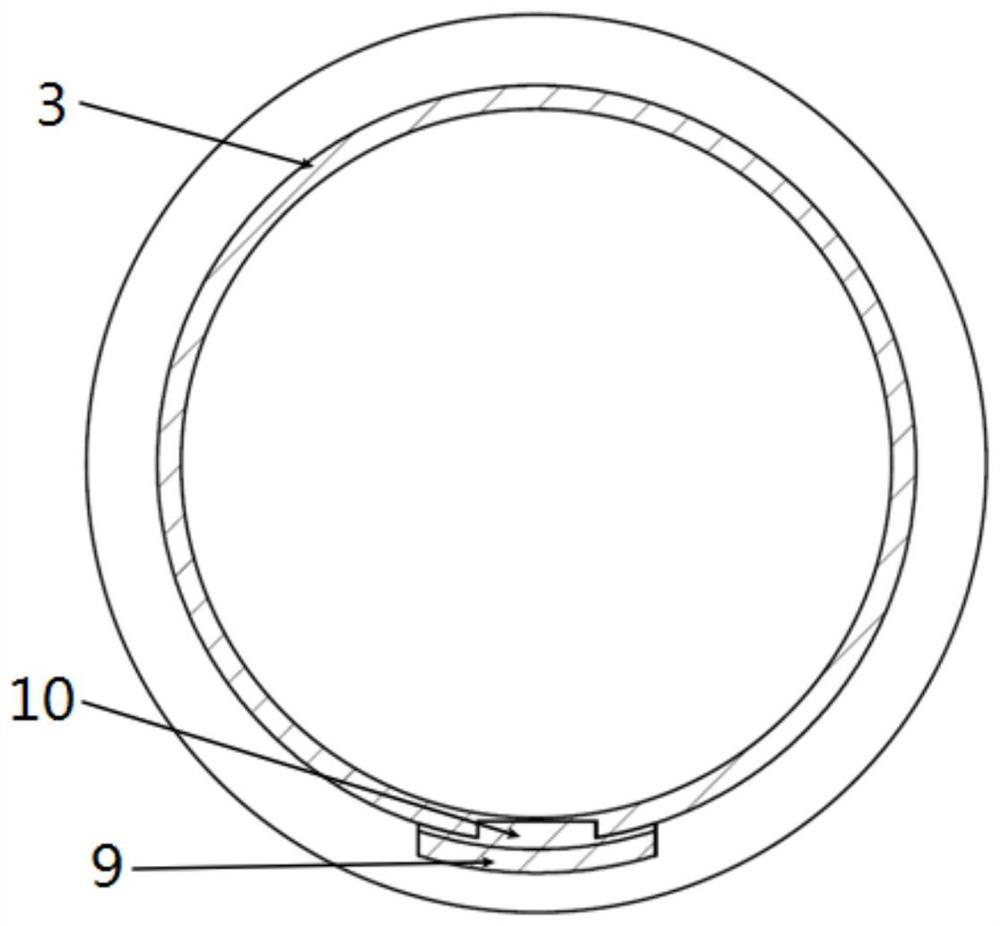

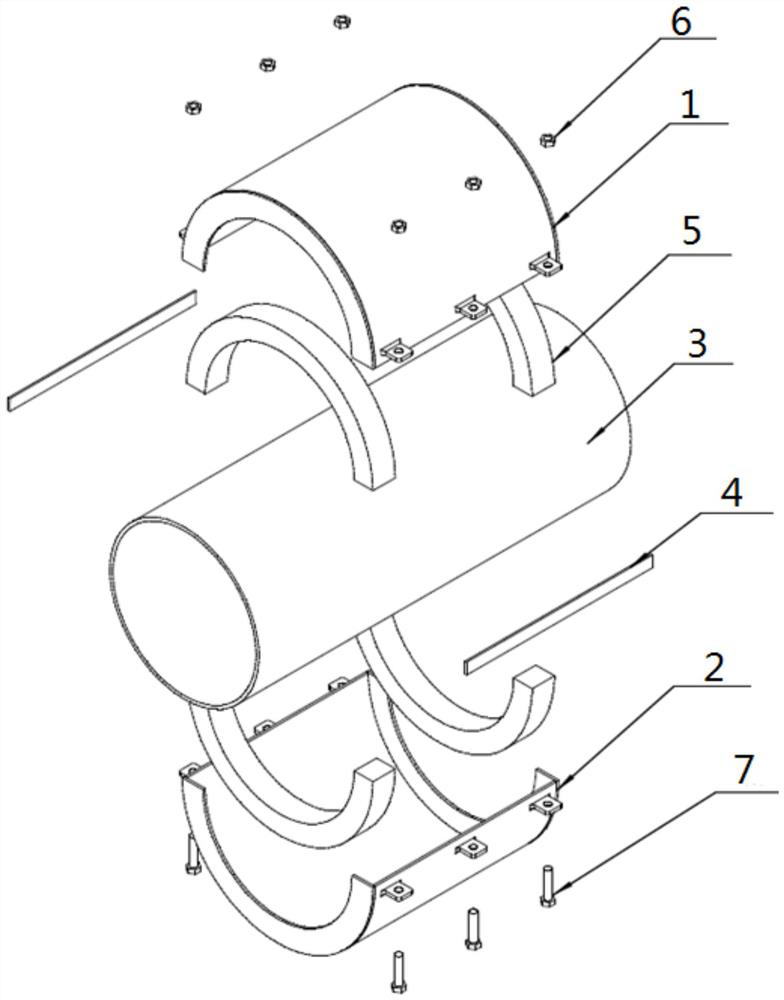

[0039] In a typical implementation of the present application, such as Figure 1-Figure 4 As shown, a corrosion reinforcement and protection method for GIS through-wall busbar shell is proposed.

[0040] A method for reinforcing and preventing corrosion of a GIS through-wall busbar housing, comprising the following steps:

[0041] Clean up the rust around the leak point, polish the corroded area of the shell 3, and form the area to be repaired;

[0042] Make a repairing steel plate 9 according to the area to be repaired, and apply an adhesive 10 on the area to be repaired and the repairing steel plate;

[0043] Adhere the corresponding steel plate to the area to be repaired, and complete the repair after drying;

[0044] The protective sleeve is sleeved on the outside of the shell corresponding to the repair area, and an annular cavity is formed between the inner wall of the protective sleeve and the outer wall of the shell;

[0045] The axial two ends of the annular cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com