A nuclear power plant generator three-flow ring sealing oil system and its airside sealing oil circuit

A technology for sealing oil and generators, applied in electromechanical devices, electrical components, electric components, etc., can solve problems such as high response speed, unfavorable oil-hydrogen pressure difference stability, etc., to ensure safe, economical and stable operation, and eliminate hidden dangers of hydrogen leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

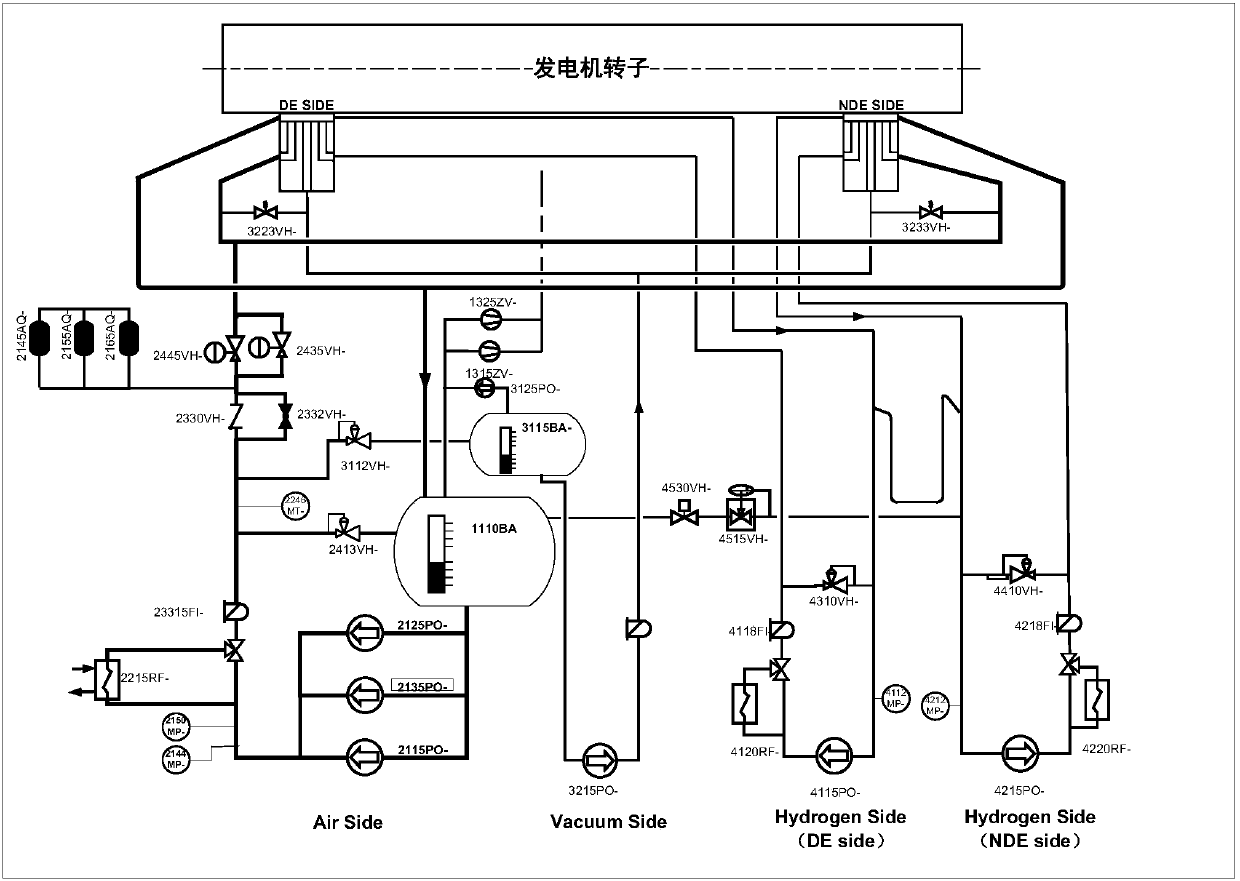

[0044] The embodiment of the present invention provides a three-flow ring sealing oil system for nuclear power plant generators, see figure 1 , the three-flow ring seal oil system may include: the air side seal oil circuit (i.e. Air Side) and the hydrogen side seal oil circuit (i.e. Hydrogen Side) connected to the seal tile of the nuclear power plant generator, and the air side seal oil circuit and the hydrogen side seal oil circuit respectively. The side seal oil circuit is connected to the vacuum side seal oil circuit (Vacuum Side), wherein the hydrogen side seal oil circuit is also connected to the driving end (DESIDE) and the non-driving end (NDE SIDE) of the generator bearing respectively.

[0045] Among them, see figure 1 , the airside sealing oil circuit may include: the main pipeline connected with the sealing tile of the generator of the nuclear power plant, the airside main oil tanks (i.e. figure 1 1110BA in), air side oil pump (ie figure 1 2115PO in), oil cooler (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com