Bolt fastened type ocean high-pressure reinforced thermoplastic pipe (RTP) connector and assembling method thereof

A fastening and fastening flange technology, applied in the direction of pipes/pipe joints/fittings, pipe connection layout, mechanical equipment, etc., can solve the problems of non-recyclable, inconvenient use, boundary damage, etc., and achieve simple and fast construction , Easy disassembly and assembly, enhance the effect of connection force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

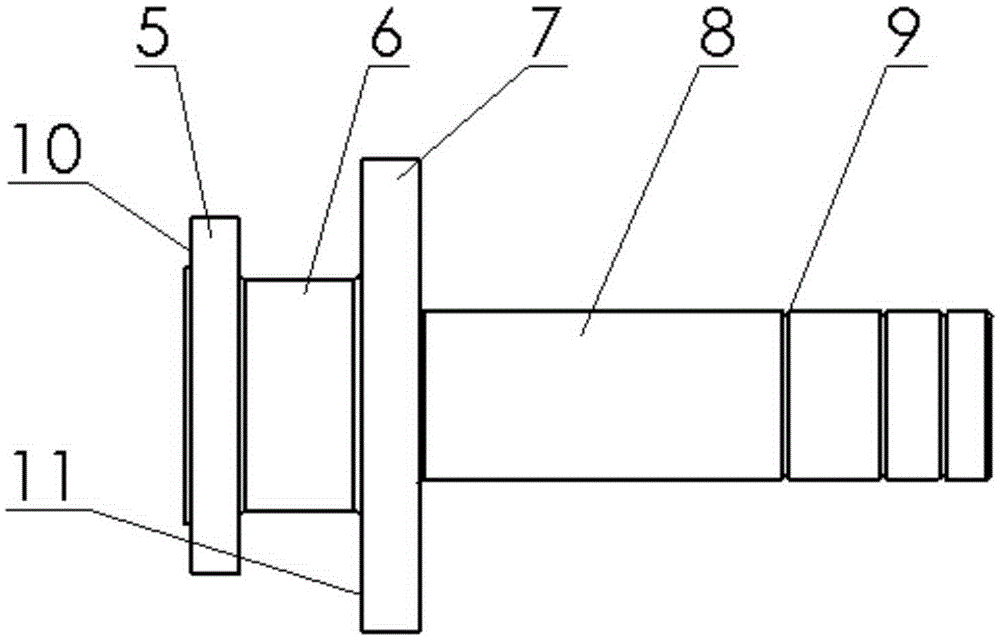

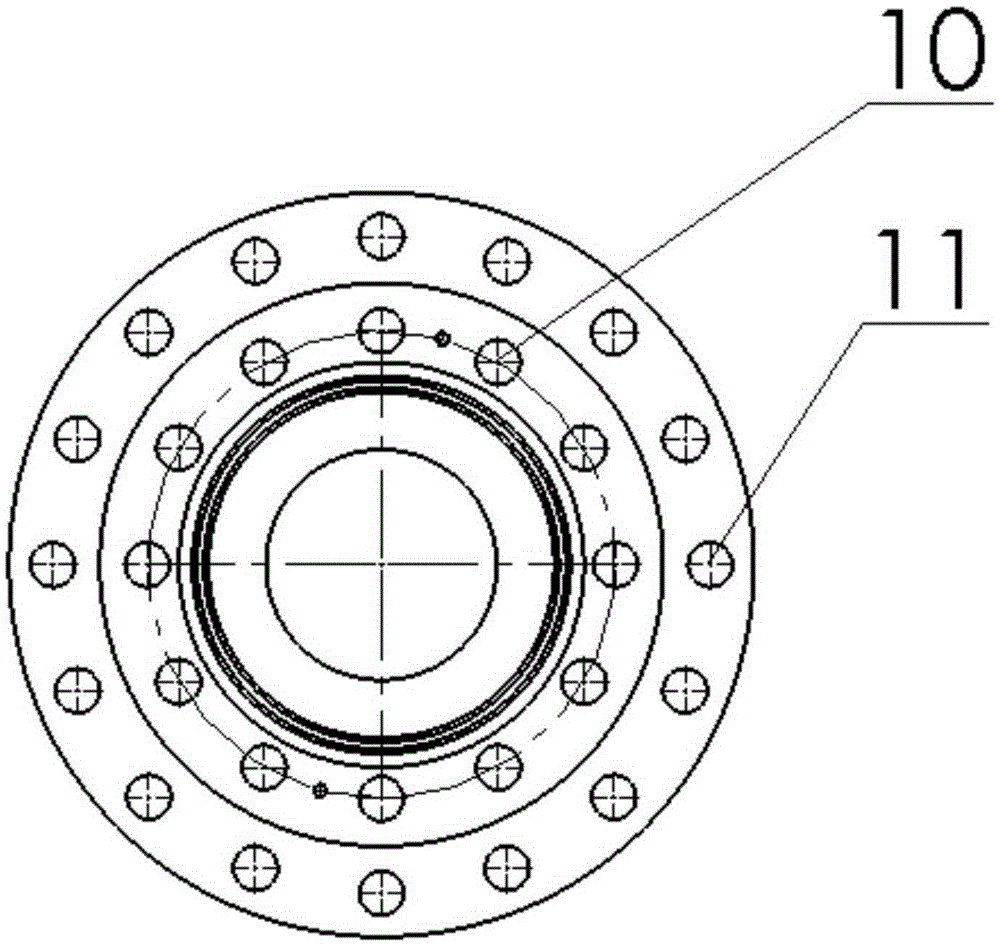

[0041] The bolt-fastened marine high-pressure RTP joint of this embodiment has a structure such as figure 1 As shown, it is mainly composed of an inner mandrel 1, an outer fastening sleeve 3, and a taper locking sleeve 2 arranged between the inner mandrel 1 and the outer fastening sleeve 3. Such as figure 2 As shown, the inner mandrel 1 includes a sealing flange 5, a connecting journal 6, a first fastening flange 7 and a steel inner pipe sleeve 8, a sealing flange 5, a connecting journal 6, and a first fastening flange 7. It is connected with the inner pipe sleeve 8 in turn to form an integrated hollow sleeve-like structure. The sealing flange 5 is a pipe connection sealing flange, which adopts a national standard flange. The connection surface can be selected according to the pressure level. Different sealing forms can be used to connect the journal 6 The size of the connecting sealing flange 5 and the first fastening flange 7 is determined by the size of the flanges at both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com