Assembly type stair

An assembled, stair technology, applied in the direction of stairs, treads, treads and vertical plate units, can solve the problems of difficult disassembly and maintenance, inconvenient use, heavy weight, etc., and achieve the effect of easy disassembly and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

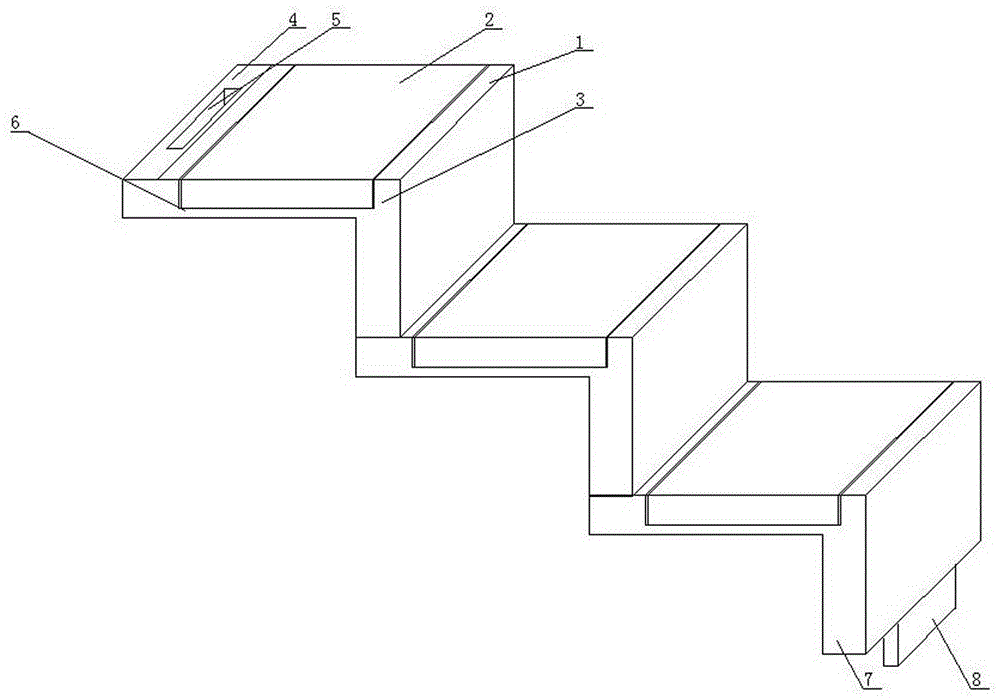

[0013] An assembled staircase, including a tread 1 and a PVC plastic floor 2 for assembling the staircase, characterized in that: the tread 1 is a specific right-angle steel plate 3, and the top surface 4 of the right-angle steel plate 3 is equipped with a rectangular hollow groove at the left end 5. The right end is equipped with a rectangular slot 6, and the bottom end of the vertical surface 7 of the right-angle steel plate 3 is equipped with a rectangular insert 8 that can be inserted into the rectangular hollow slot 5.

Embodiment 2

[0015] An assembled staircase is characterized in that: the PVC plastic floor 2 is installed in a rectangular groove.

Embodiment 3

[0017] An assembled staircase is characterized in that: the rectangular insert 8 can be inserted into the rectangular hollow groove 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com