Conductive rubber particle, and production method and application thereof

A technology of conductive rubber particles and rubber particles is applied in the preparation of antistatic materials and in the field of electrical conductivity, which can solve the problems of uneven dispersion, strong intermolecular interaction, and easy agglomeration of nanoparticles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

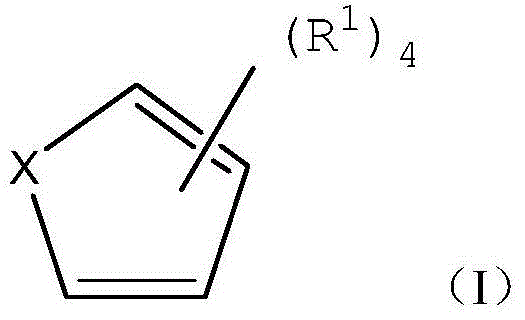

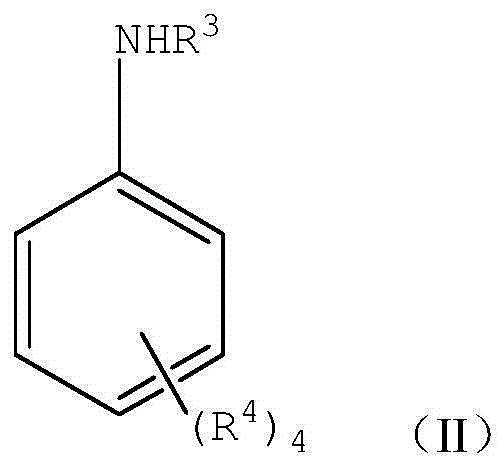

Method used

Image

Examples

Embodiment 1

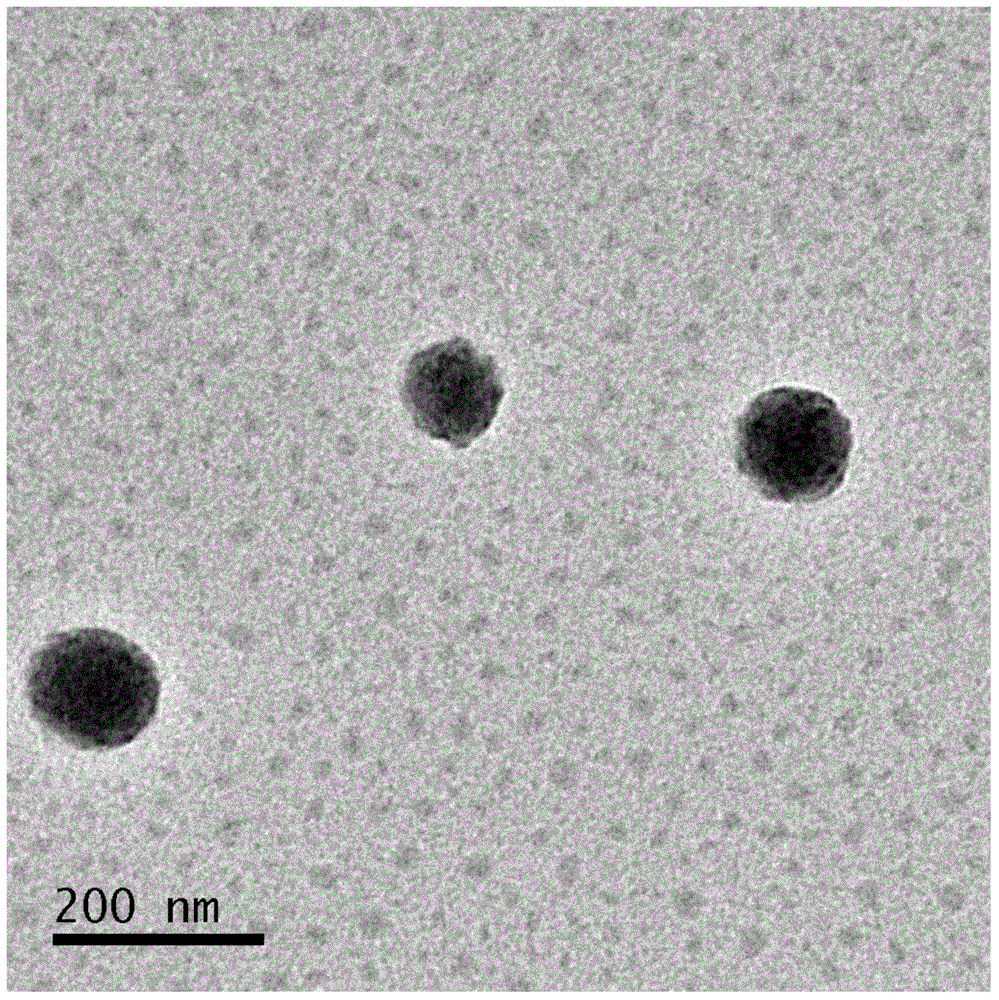

[0055] Take 30 g of radiation cross-linked nitrile latex and add it into a reactor equipped with mechanical stirring, and add pyrrole monomer and start to swell for 1 hour while stirring. Then 50ml of polyvinylpyrrolidone (K30, Xilong Chemical Co., Ltd.) aqueous solution was added to the nitrile latex, and after stirring for 10 minutes, ferric chloride and p-toluenesulfonic acid aqueous solution were simultaneously added dropwise. After the dropwise addition is completed, the reaction system is cooled in an ice-water bath, and then 30wt% hydrogen peroxide solution is added to start the reaction to ensure that pyrrole, polyvinylpyrrolidone (repeating unit), ferric chloride, p-toluenesulfonic acid and peroxide The concentrations of hydrogen were 0.066M, 0.057M, 0.0001M, 0.033M and 0.079M, respectively. After 48 hours of reaction, stop to obtain nitrile / polypyrrole conductive rubber emulsion. The z-average particle diameter of the nitrile / polypyrrole conductive rubber latex part...

Embodiment 2

[0057] Method is the same as embodiment 1, but the nitrile latex in embodiment 1 is replaced by carboxylated nitrile latex, and in the reaction system, pyrrole, polyvinylpyrrolidone (repeating unit), ferric chloride, p-toluenesulfonic acid and hydrogen peroxide The concentrations are 0.066M, 0.057M, 0.0001M, 0.0132M and 0.132M, respectively. After 48 hours of reaction, carboxylated nitrile / polypyrrole conductive rubber emulsion was obtained. The z-average particle diameter of the carboxylated nitrile / polypyrrole conductive rubber latex particles is 180nm. The emulsion is spray-dried to obtain carboxylated nitrile / polypyrrole conductive rubber nanoparticles. The surface resistance of the product is about 8.9×10 5 Ω / □.

Embodiment 3

[0059] The method is the same as in Example 1, but the concentrations of pyrrole, polyvinylpyrrolidone (repeating unit), ferric chloride, p-toluenesulfonic acid and hydrogen peroxide in the reaction system are respectively 0.066M, 0.057M, 0.0001M, 0.132M and 0.033 M, and the reaction was carried out at 23°C instead of in an ice-water bath, and the reaction was stopped after 32 hours to obtain a nitrile / polypyrrole conductive rubber emulsion. The z-average particle diameter of the nitrile / polypyrrole conductive rubber latex particles is 65nm. The emulsion is spray-dried to obtain nitrile / polypyrrole conductive rubber nanoparticles. The surface resistance of the product is about 5.6×10 3 Ω / □.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com